Sintering machine air volume control method and system based on sound source characteristics

A control method and sintering machine technology, applied to the furnace control device, furnace type, furnace, etc., can solve the problems of increasing the air volume of the sintering main exhaust fan, excessive combustion of sinter, and energy waste of the main exhaust fan, etc., to reduce redundancy Air volume, reduce production energy consumption, improve the effect of sinter quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

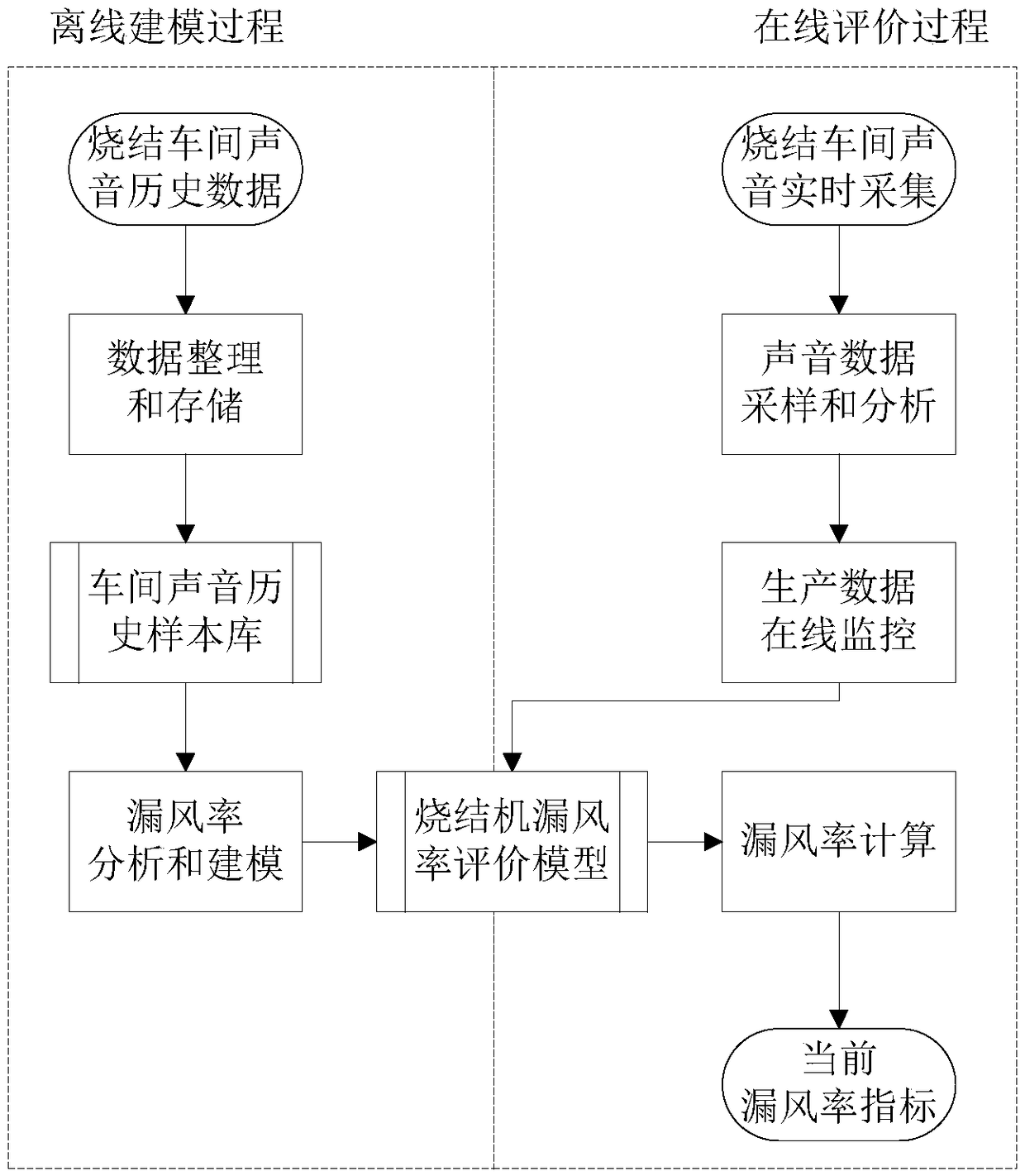

[0035] combine figure 1 , this embodiment provides a sintering machine air volume control method based on sound source characteristics,

[0036] The workshop where the sintering machine is located is provided with several sound signal collectors, and the outlet of the main exhaust fan is provided with an air volume detector. The method includes the following steps:

[0037] Step 1: Collect the sound data of the sintering workshop under normal working conditions and fault conditions respectively; reconstruct the source of the sound data of the sintering workshop to obtain the reconstruction sample set of the normal working source and the source reconstruction sample set of the air leakage fault; use Obtain the reconstruction sample set of the normal working signal source and the reconstruction sample set of the air leakage fault signal source to construct the evaluation model of the air leakage rate of the sintering machine based on the characteristics of the sound source;

[...

Embodiment 2

[0042] combine figure 2 As the specific scheme of embodiment 1, the specific method of constructing the air leakage rate evaluation model of the sintering machine based on the characteristics of the sound source in the above step 1 is as follows:

[0043] Step 1.1: Process the collected sound data of the sintering workshop to obtain the normal data set X normal and air leakage fault data set X fault ;

[0044] Step 1.2: The normal data set X normal and air leakage fault data set X fault Mix and proceed independent component analysis to obtain the source reconstruction model of the sound signal of the sintering machine workshop; the specific method is: Step 1.2.1: For the mixed normal data set X normal and air leakage fault data set X fault The data in is zero-meanized and whitened, and the sample Z after whitening is obtained;

[0045] Step 1.2.2: According to the estimation of the number of live sound signal sources, the initialization vector W={w 1 ,w 2 ,...w k}, w...

Embodiment 3

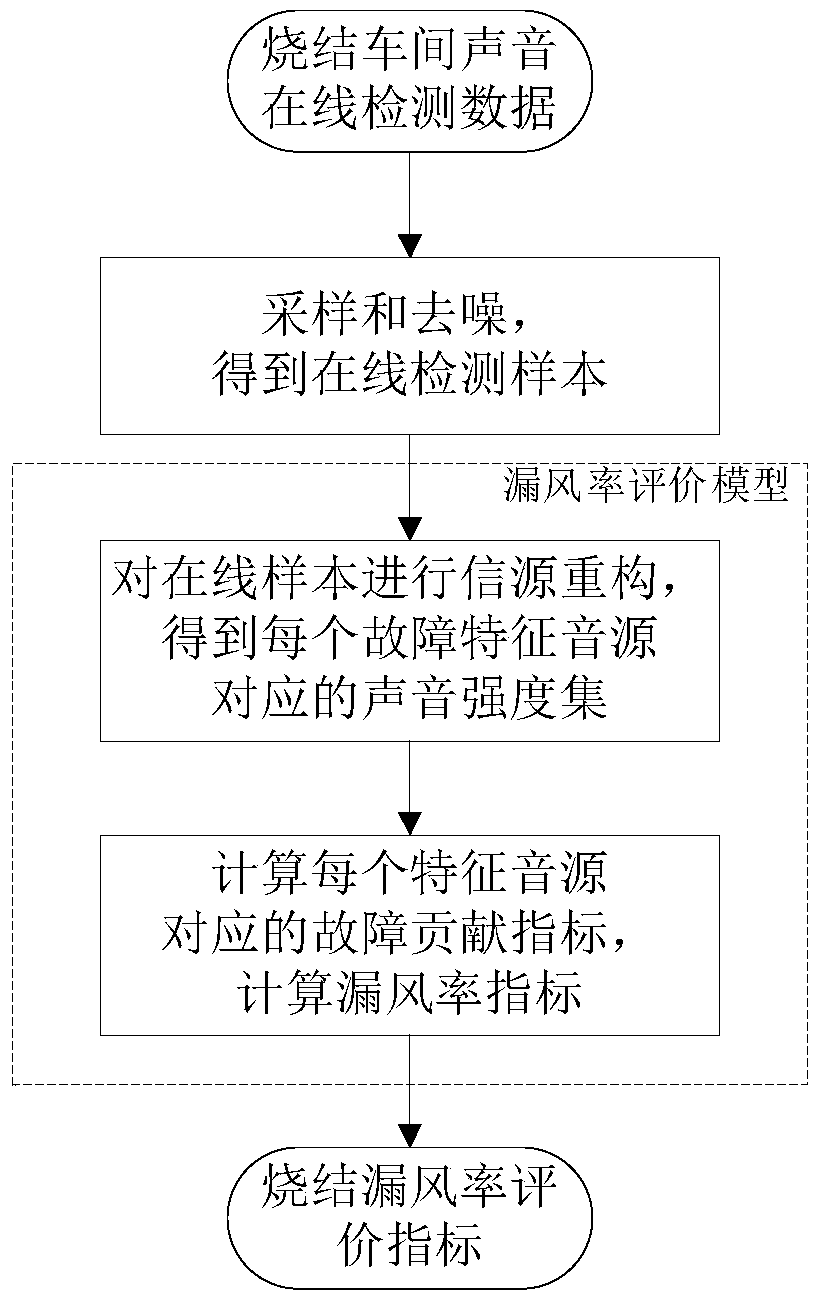

[0054] combine image 3 , as the specific scheme of embodiment 1, the method for obtaining the air leakage rate index of the sintering machine based on the characteristics of the sound source in the above step 2 includes:

[0055] Step 2.1: Sampling and denoising the collected sound data of the sintering workshop to obtain online sound samples;

[0056] Step 2.2: Analyze the sound source of the online samples, and obtain the sound intensity set S corresponding to the online fault characteristic sound source j , S j ={s j1 ,...,s jk}, where j is the serial number of the current sample, i is the serial number of the characteristic sound source, s ji is the sound intensity corresponding to the i-th feature of the current sample;

[0057] Step 2.3: Calculate the online samples at the characteristic frequency f i Air leakage fault contribution index at Accumulate the air leakage fault contribution indicators corresponding to each characteristic frequency to obtain the sinte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com