Manufacturing method of string lamp wire

A production method and lamp stringing technology, which are applied in the direction of lighting devices, electric light sources, lighting and heating equipment, etc., can solve the problems of complex realization process and weak connection, achieve the level of firm installation, improve safe use, and simple steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

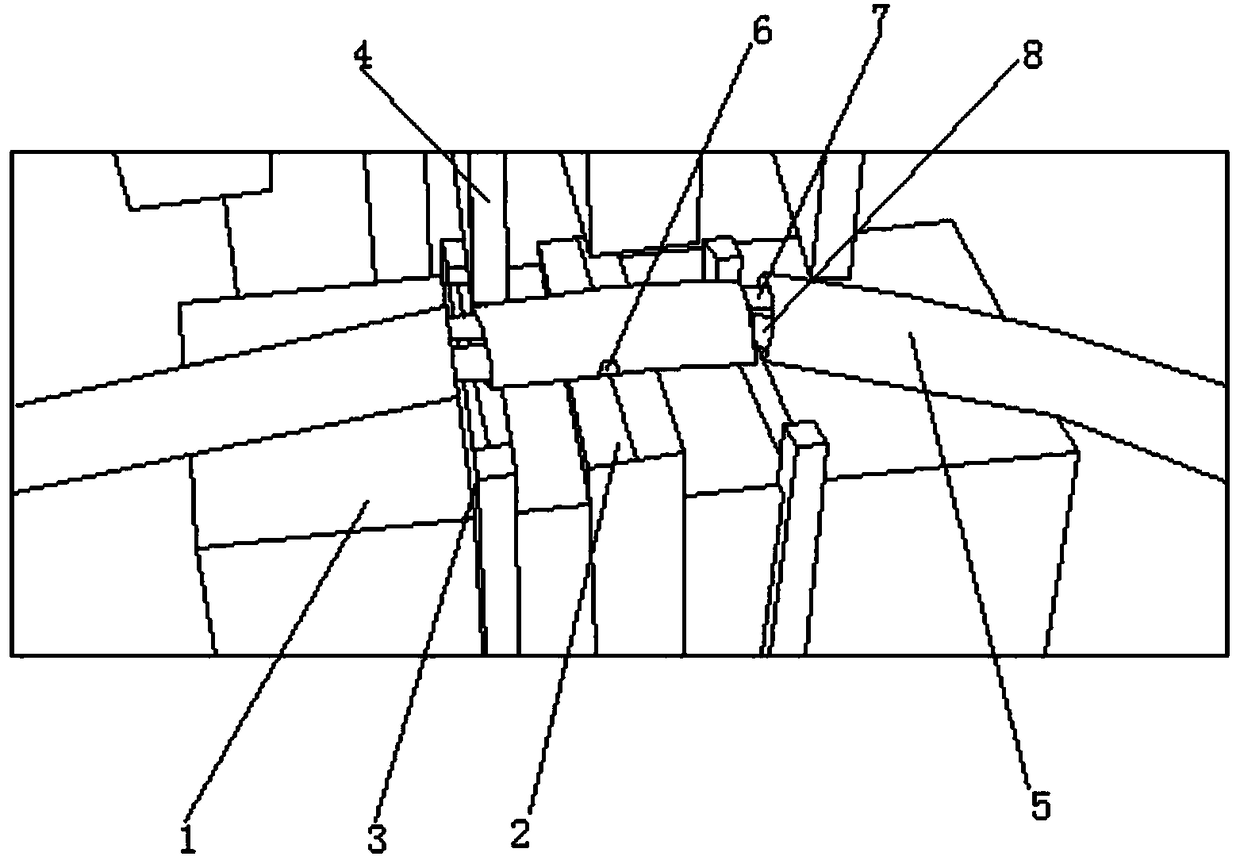

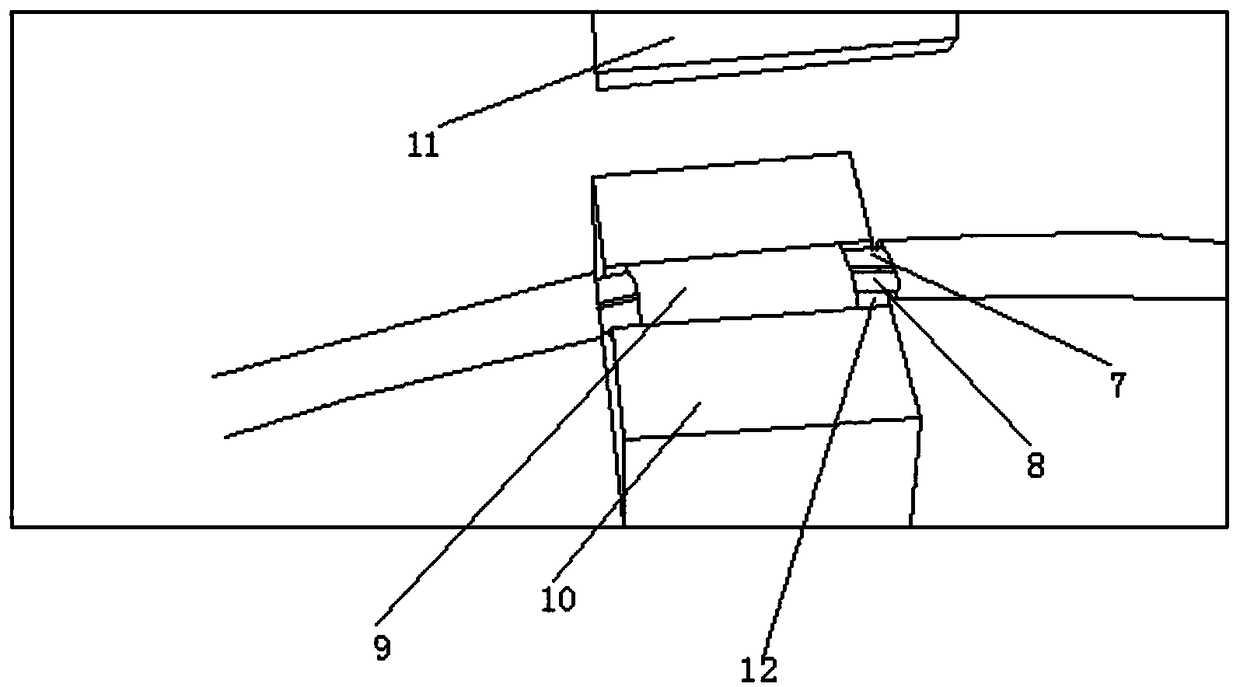

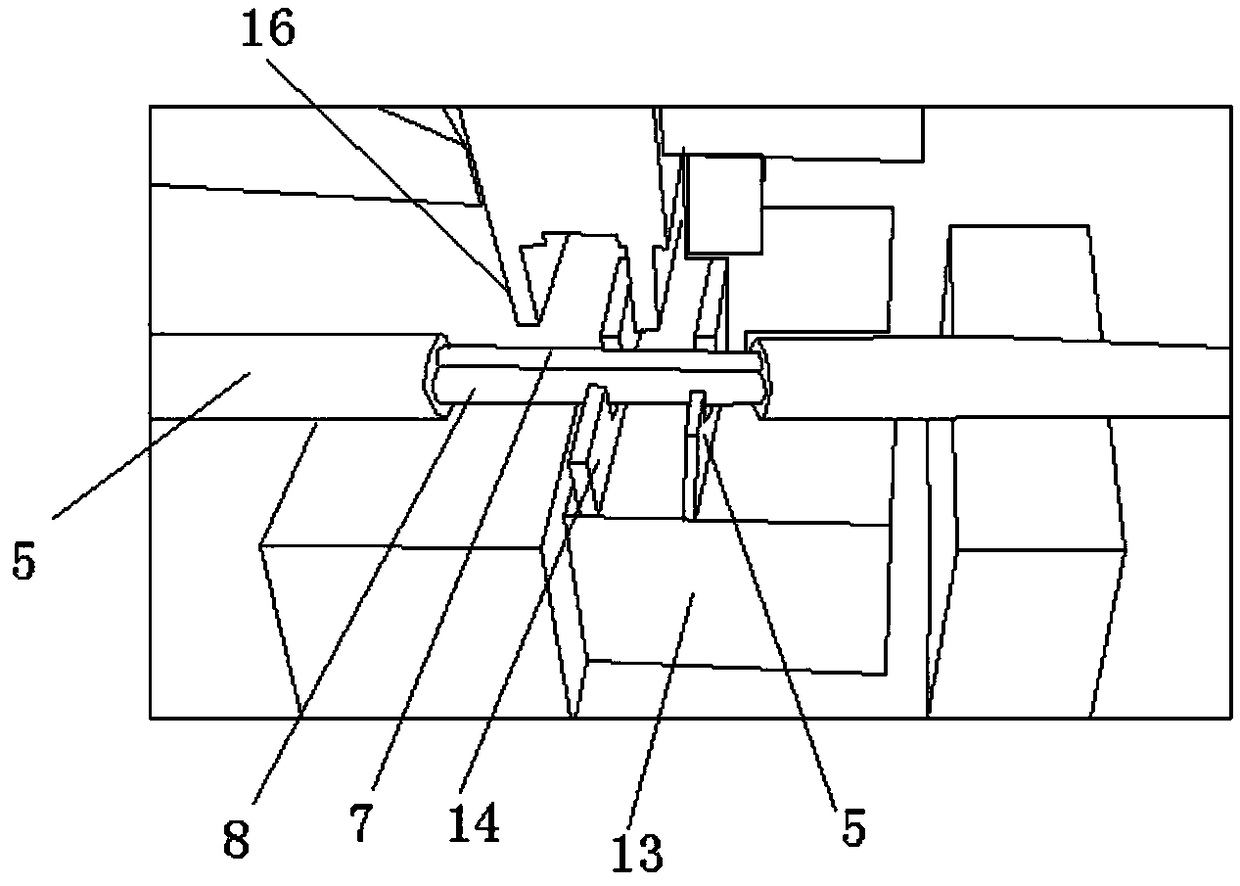

[0036] Such as Figure 1 ~ Figure 4 As shown, a method for making a string of lights includes the following steps:

[0037] S1) Winding and marking lines; use a wire winder with a set distance, and wind the light string wire back and forth on the wire winder according to the fixed winding direction. After the light string wire is wound, put the head and tail of the light string wire first After fixing it, tie it tightly with a cable tie before starting to draw the line;

[0038] S2) Stripping of the lamp strings; use a peeling machine to remove the skin of the lamp strings. The peeling machine has a peeling platform 1, and the middle part of the peeling platform 1 is provided with a middle boss 2. The left and right sides of the middle boss 2 are respectively There is a lower skin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com