Friction reduction bearing and preparation method thereof

An anti-friction bearing and blind hole technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as weak adhesion, affecting performance, and stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

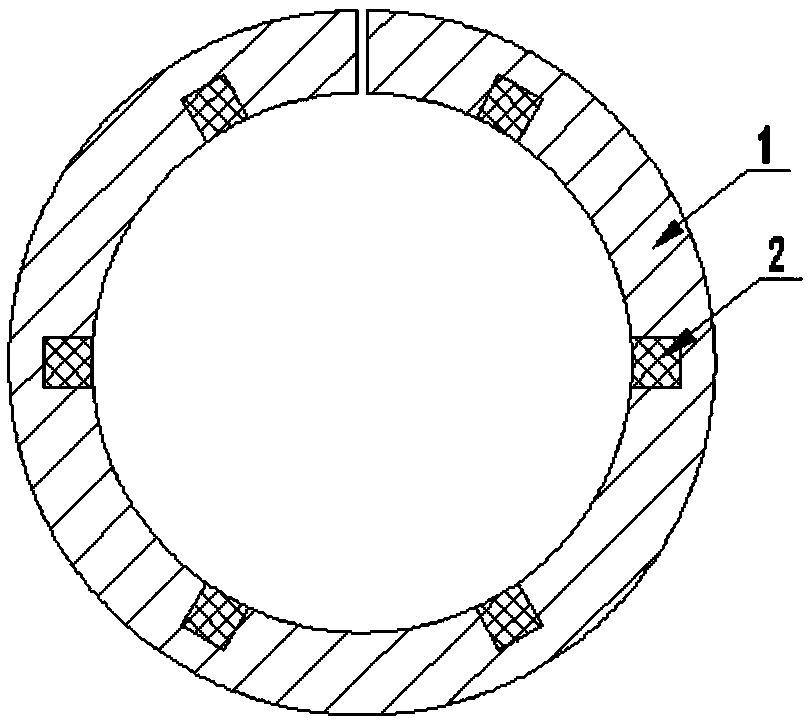

[0027] An antifriction bearing such as figure 1 and figure 2 As shown, it includes a matrix 1 and a lubricant, the lubricant is a solid lubricant, the matrix 1 is a hollow cylinder, the inner wall of the matrix 1 is radially provided with a blind hole 2, and the lubricant is arranged in the blind hole 2 Inside, the bottom area of the blind hole 2 is larger than the opening area, and there is interference fit and clearance fit between the lubricant and the blind hole 2 .

[0028] The material of the plate in the embodiment of the present invention is iron, copper or aluminum. The lubricant is made of graphite grains or modified PTFE.

[0029] The antifriction bearing of the present invention, the preparation process comprises the following steps,

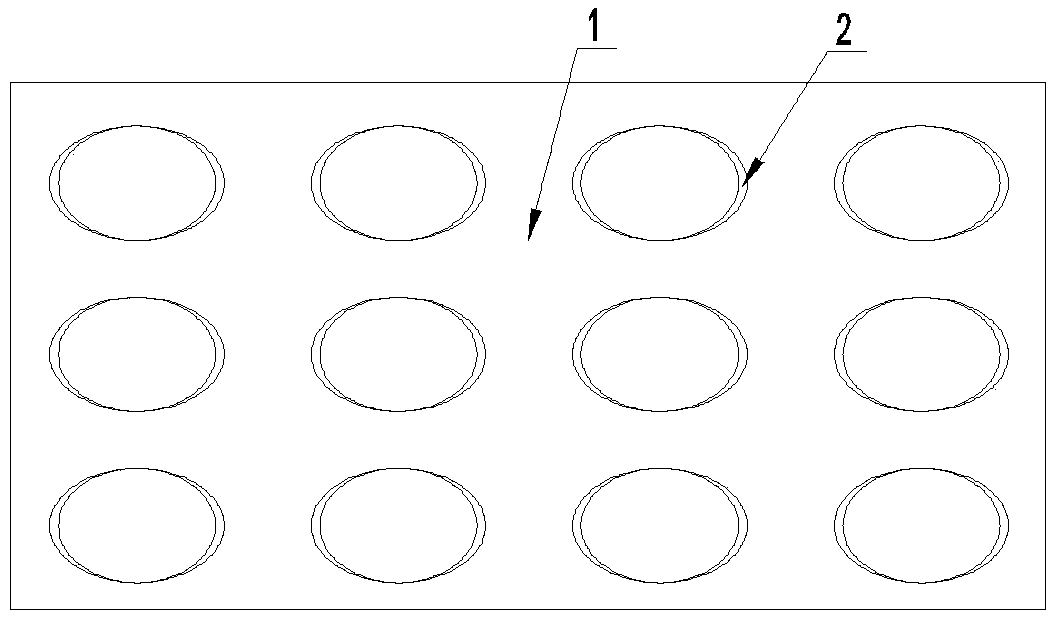

[0030] S10. Preparing the substrate: preparing the plate used in the substrate 1;

[0031] S20, making a blind hole: machining a blind hole 2 on one side of the plate;

[0032] S30, cleaning debris: removing debris in the bli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com