Piling process of conduit frame pile pipes

A jacket and process technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as increasing costs, continuing to sink until submerged in sea mud, and increasing platform complexity, so as to reduce costs and increase market share Competitiveness and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

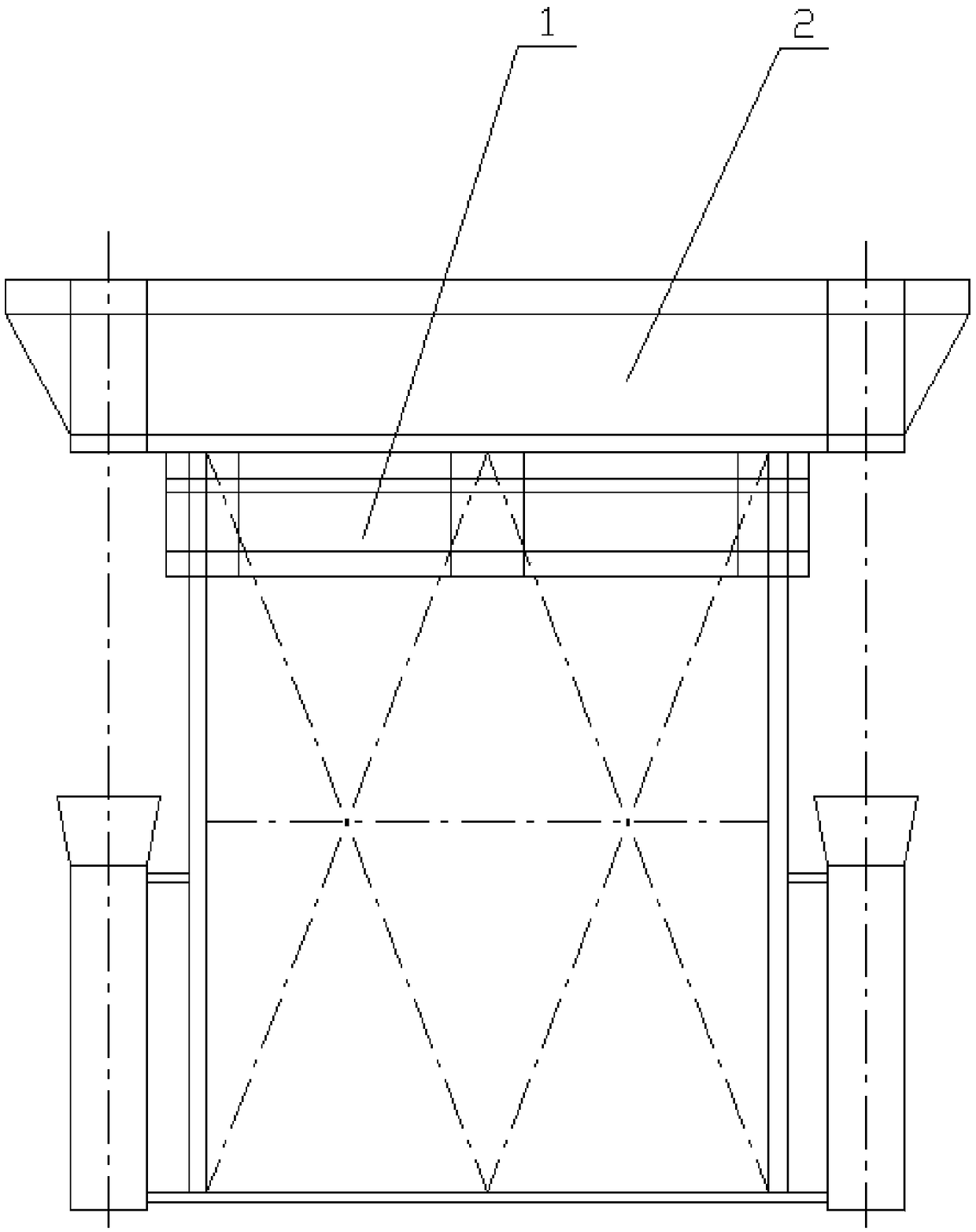

[0027] see Figure 1~4 , a jacket pile pipe piling process that the present invention relates to, said process includes the following steps:

[0028] Step 1. The crane on the construction ship lifts the platform one by one to the target sea surface;

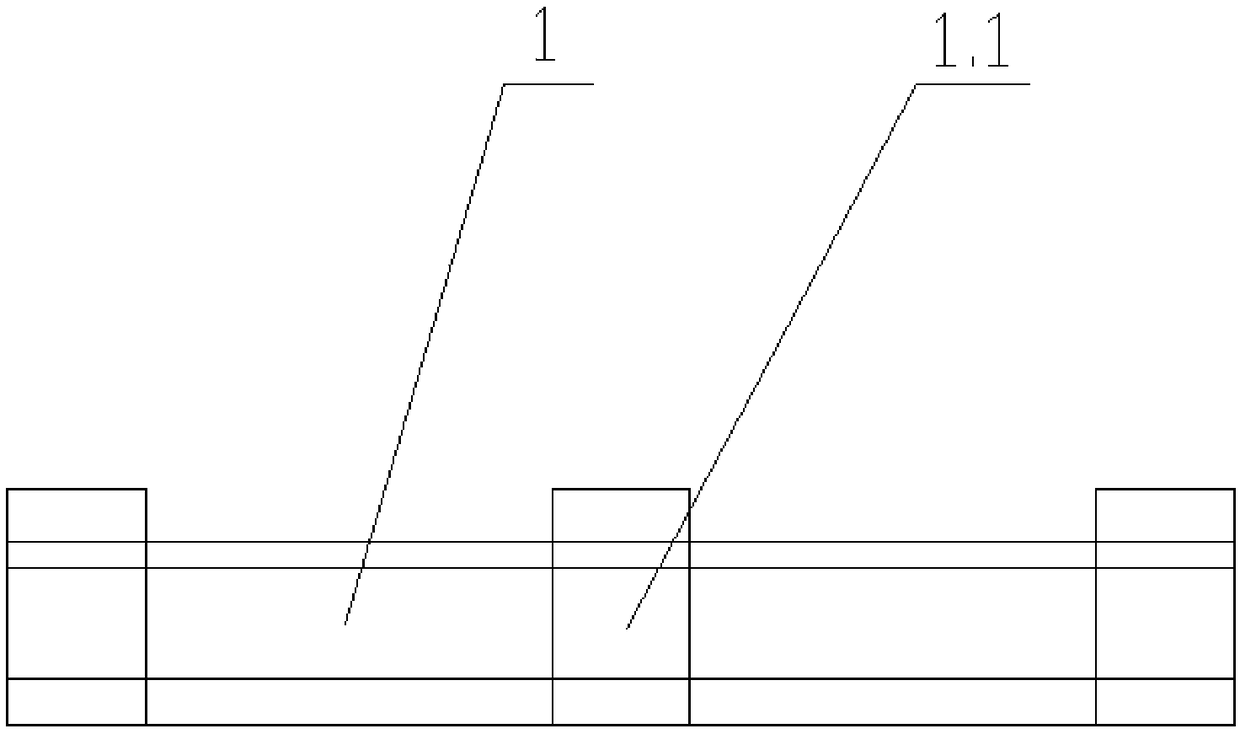

[0029] Step 2, the auxiliary pile inserted into the auxiliary pile hole 1.1 of the platform 1 is inserted on the seabed;

[0030] Step 3, hoist platform two 2 to platform one 1 by the crane, and connect platform one 1 and platform two 2;

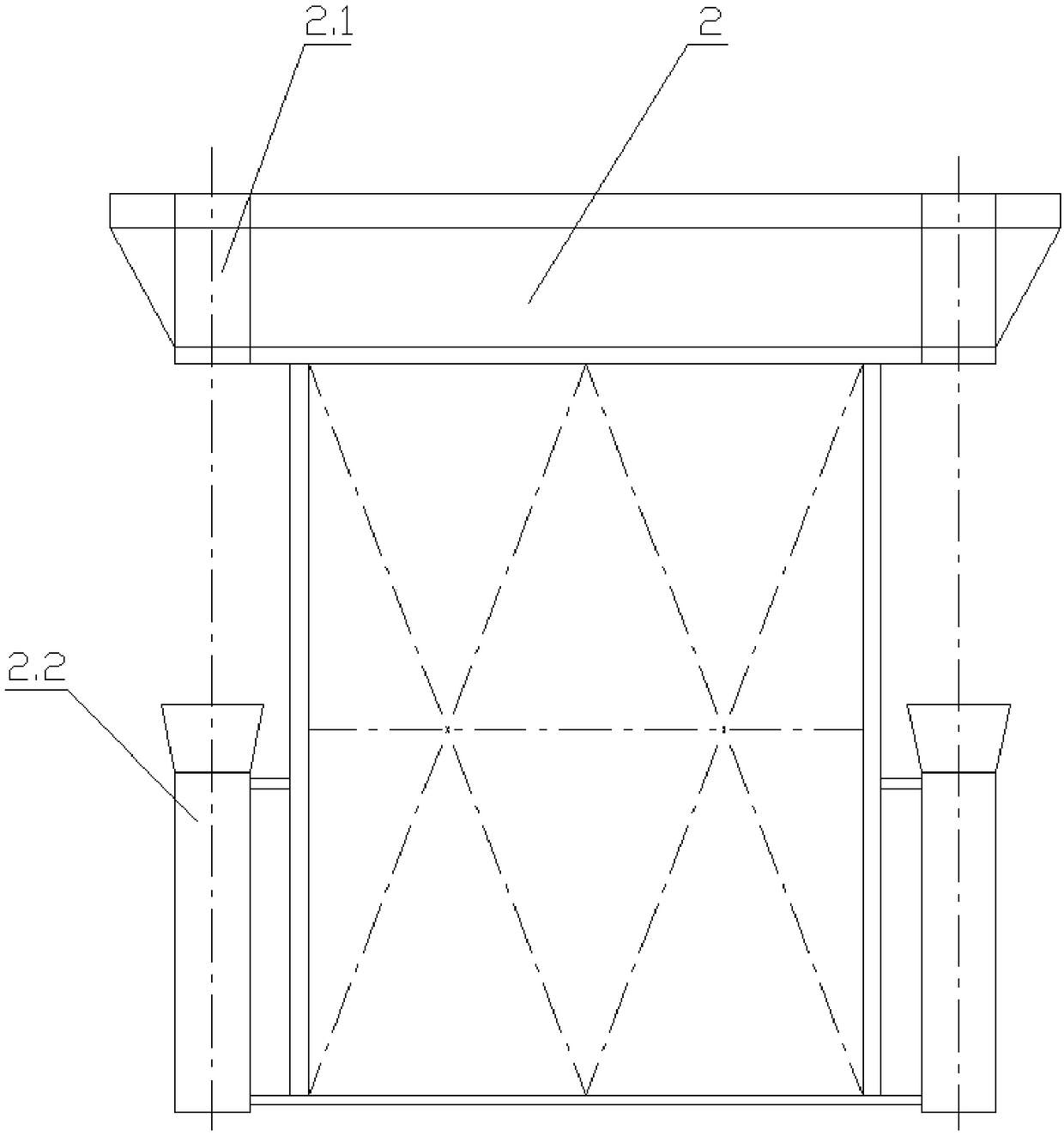

[0031] Step 4, the engineering pile is inserted into the upper guide hole 2.1 of the engineering pile and the lower guide hole 2.2 of the engineering pile of the platform two 2;

[0032] Step 5. After the top of the engineering pile is located below the upper guide hole 2.1 of the engineering pile, insert the connecting pipe into the upper guiding hole 2.1 of the engineering pile, and through the connecting pipe, the engineering pile continues to be inserted downward into the seabed in the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com