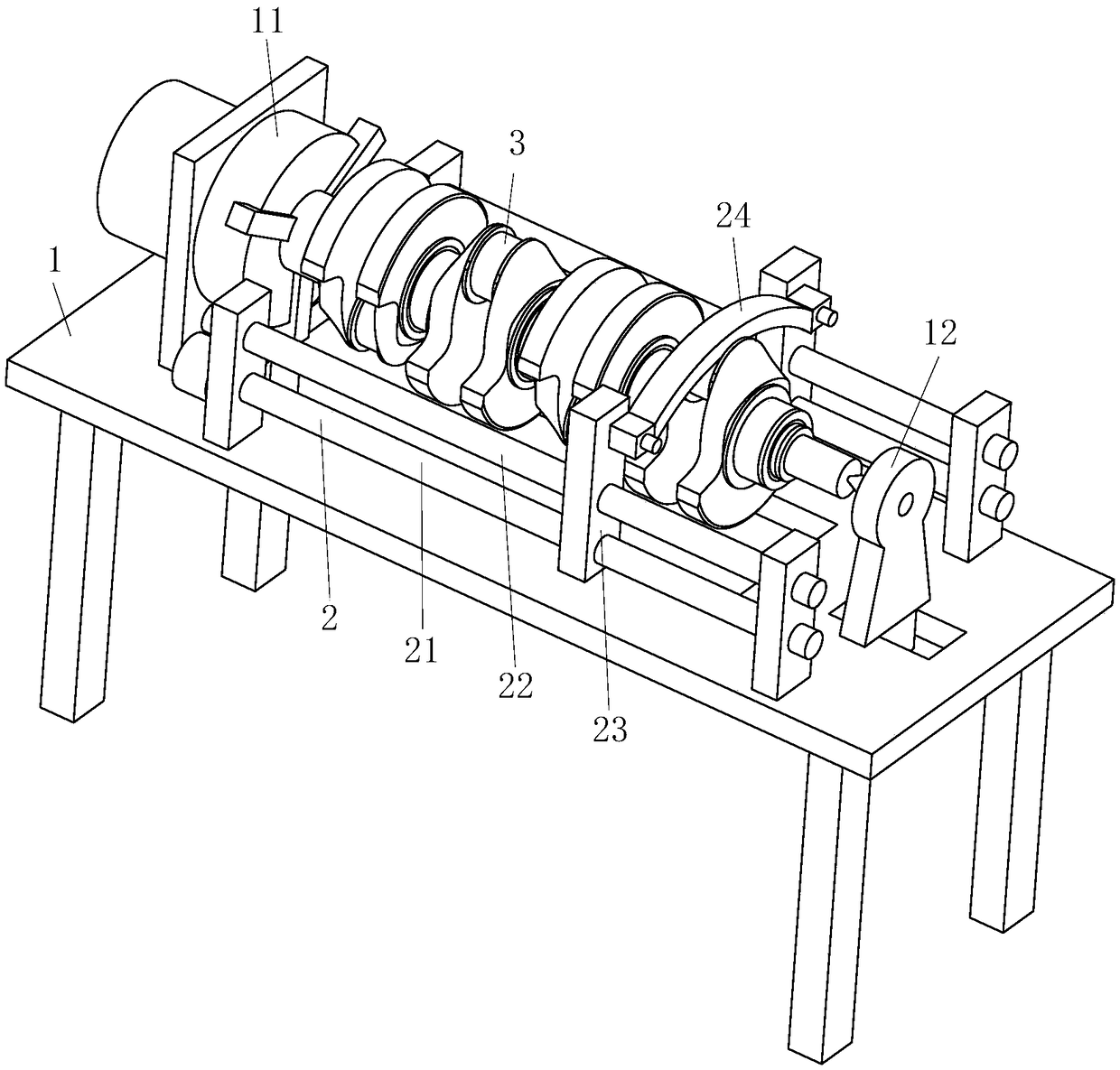

Electro-brush plating repairing machine tool for automobile engine crankshaft

An automobile engine and electric brush plating technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems affecting the whole machine work, uneven brush plating, low efficiency, etc., to improve repair efficiency, improve brush plating efficiency, The effect of shortening the drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

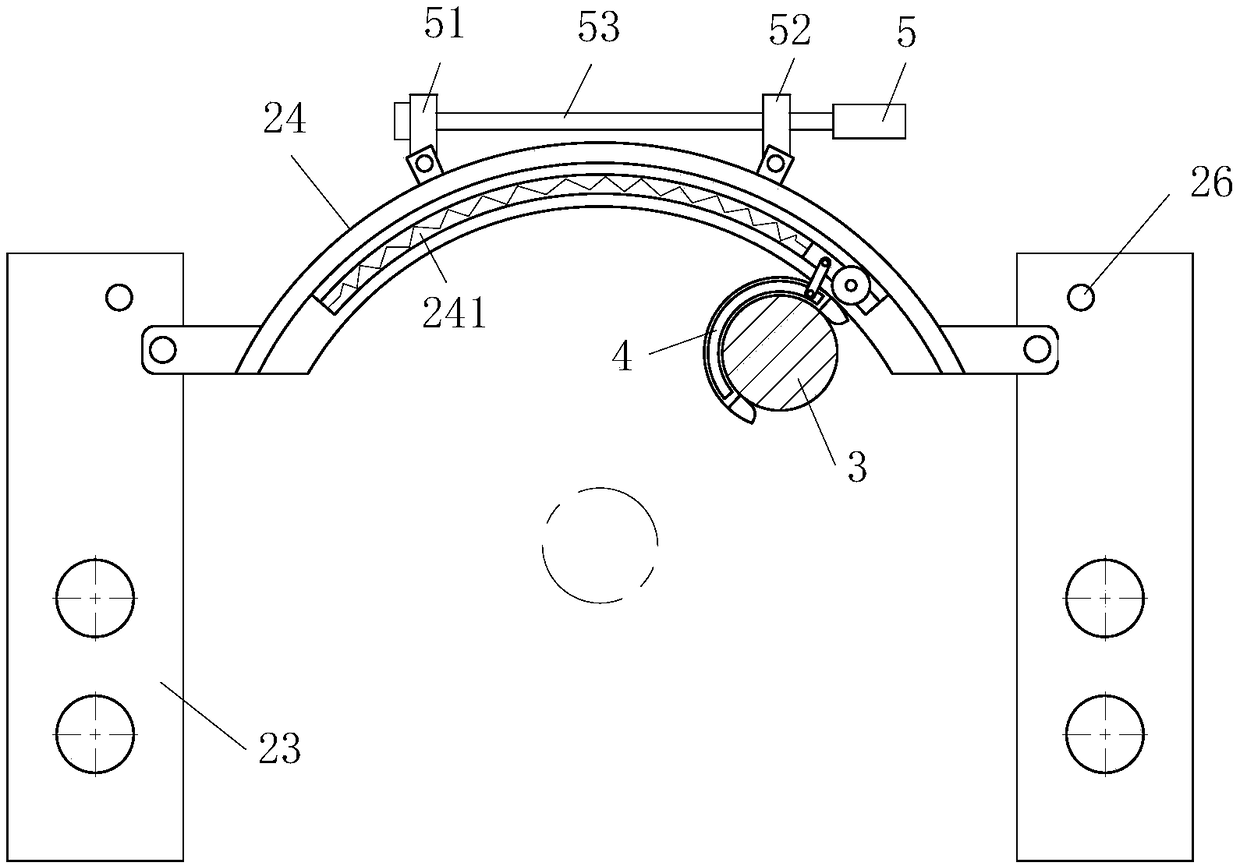

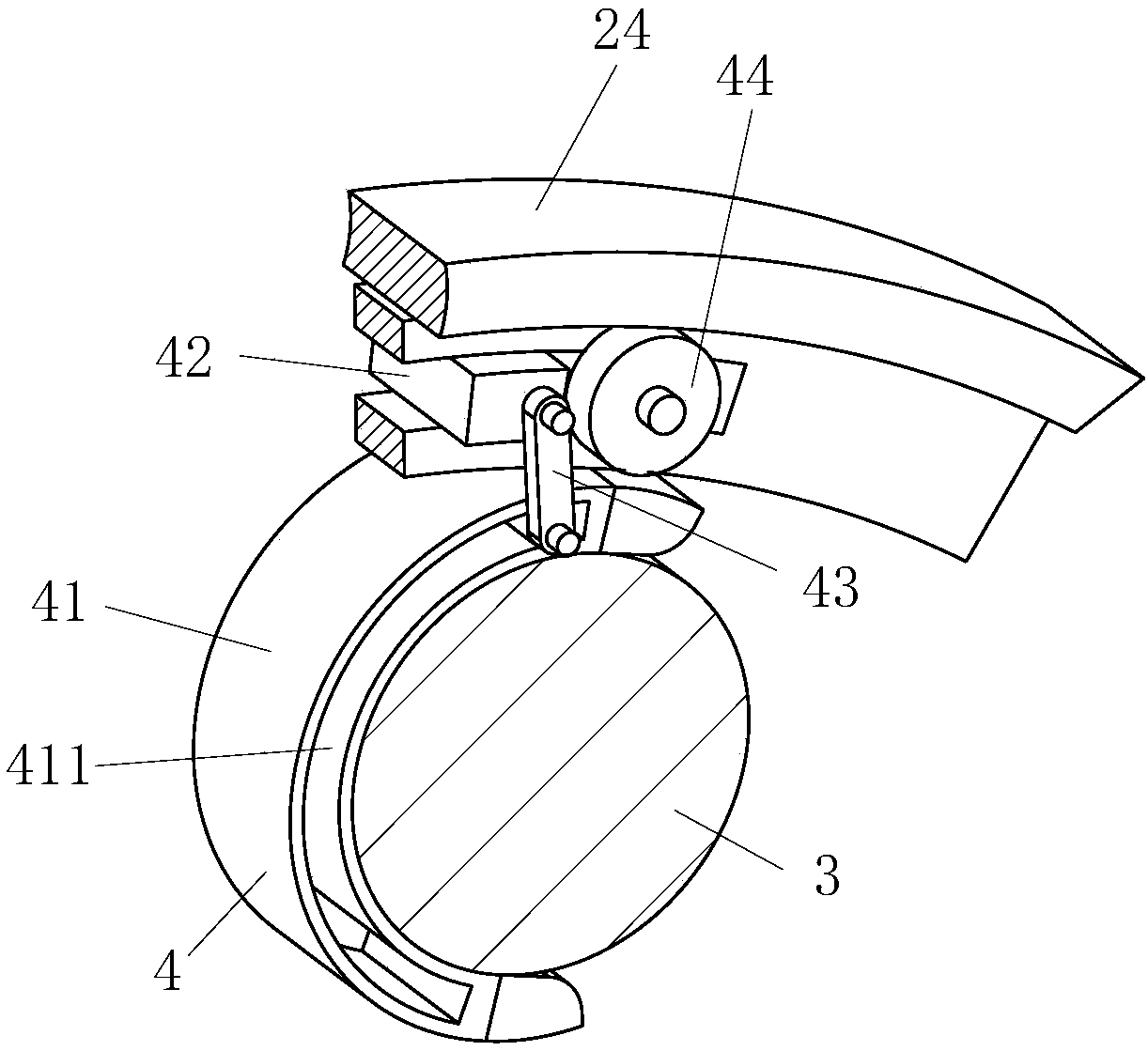

[0023] As an embodiment of the present invention, the brush plating device 4 includes a brush ring 41, a second slider 42, a support plate 43 and a gear 44; the brush ring 41 is semicircular; the brush ring 41 The inner ring is provided with hair bundles; the brush ring 41 is provided with a through first chute 411, and the arc plate 24 is provided with a second chute 241, and a second slider is slidably installed in the second chute 241 42, the second slider 42 is connected to one end of the second chute 241 through a spring; a support plate 43 is provided on both sides of the second slider 42; a sliding installation is provided between the two support plates 43 on the first chute 411 The inner roller shaft; one side of the support plate 43 is provided with a gear 44 that is rotatably installed on the second slider 42; groove; the outer ring of the brush ring 41 is provided with a tooth groove meshing with the gear 44; when the second slider 42 slides along the arc plate 24, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com