Steel belt elevator

A steel belt and elevator technology, applied in the field of elevator equipment, can solve problems such as the influence of guide rail installation cycle, high installation difficulty, inaccurate installation positioning, etc., and achieve the effect of low elevator building shaft requirements, shortening installation time, and reducing connection structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

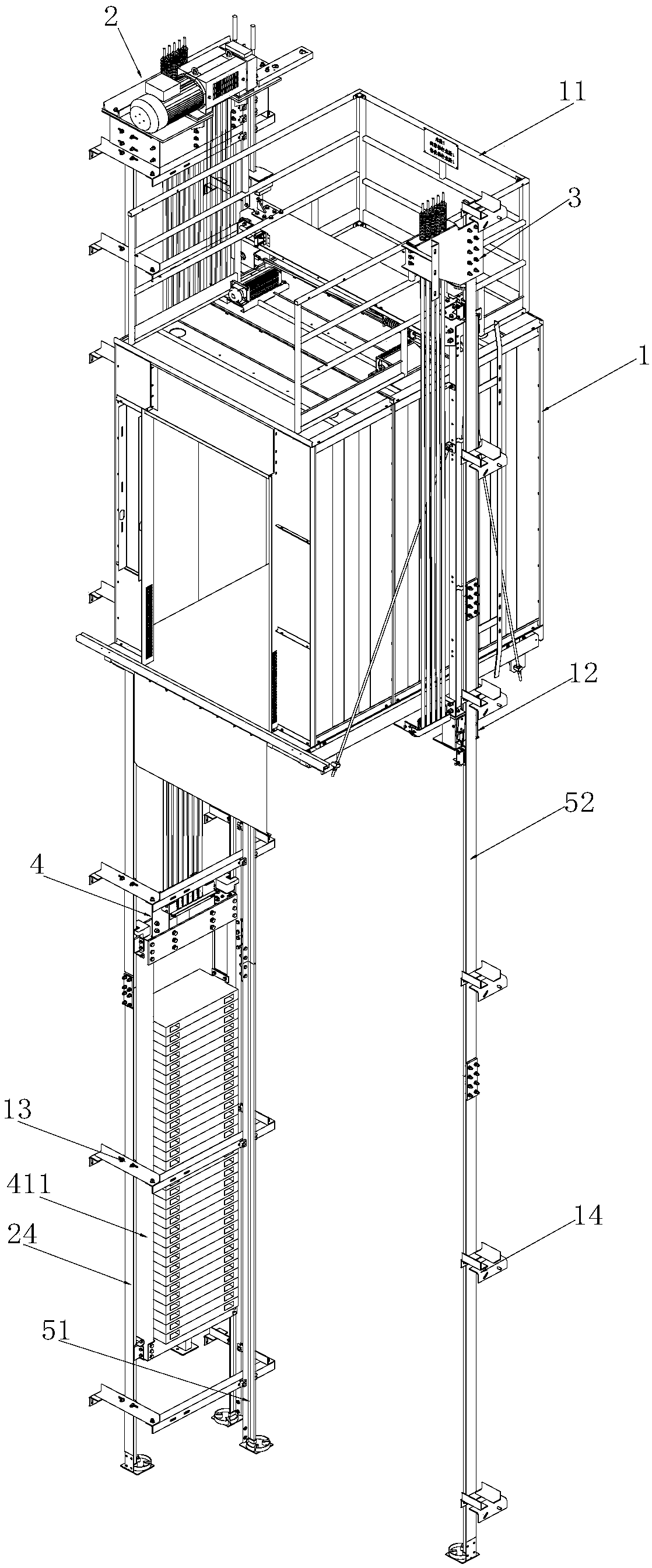

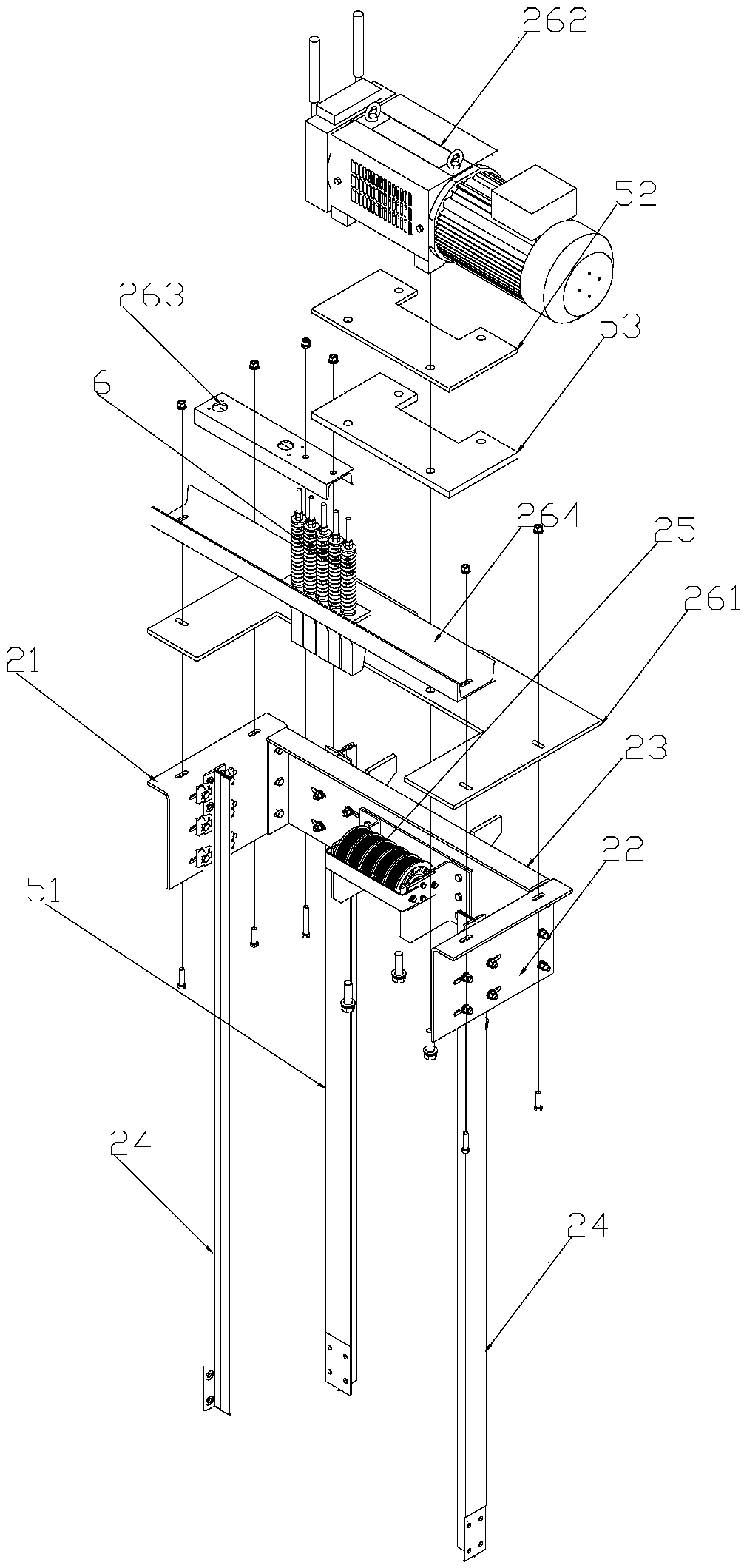

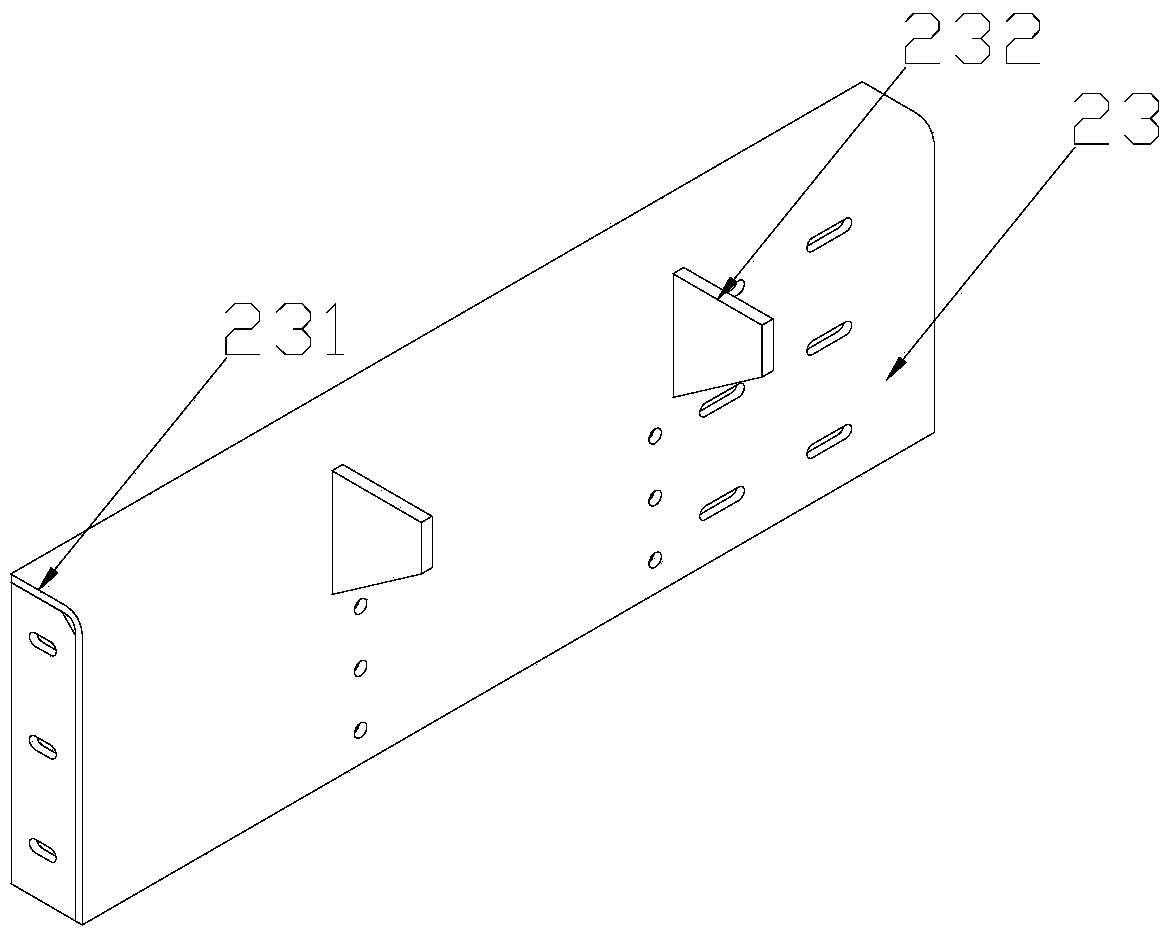

[0023] Such as Figure 1-Figure 4 As shown, the steel belt elevator described in this embodiment includes an elevator car 1 and a load-bearing device 2 used in conjunction with the elevator car 1, a rope head device 3, and a counterweight device 4. The top of the elevator car 1 is provided with The safety guardrail 11 of the side opening of the car door, the upper left and right sides of the safety guardrail 11 on the elevator car 1 are respectively provided with a load-bearing device 2 for carrying the weight of the elevator car and a rope end device 3 for fixing the elevator driving steel belt, The elevator car 1 is provided with a safety tongs 12 used in conjunction with the car guide rails, a counterweight device 4 for balancing the weight of the car is provided below the load-bearing device 2, and the load-bearing device 2 is formed by the first side plate 21 and the second side plate 22 are composed of a bolt structure clamping connecting plate 23, the outer surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com