Closed loop type conveying system for building concrete wallboard prefabricated part production line

A technology of prefabricated components and conveying systems, applied in conveyors, mechanical conveyors, manufacturing tools, etc., can solve the problems of low production efficiency of production lines, no organic connection, large space occupation, etc., to improve production efficiency, reduce engineering costs, The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to clearly illustrate the design concept of the present invention, the present invention will be described below in conjunction with examples.

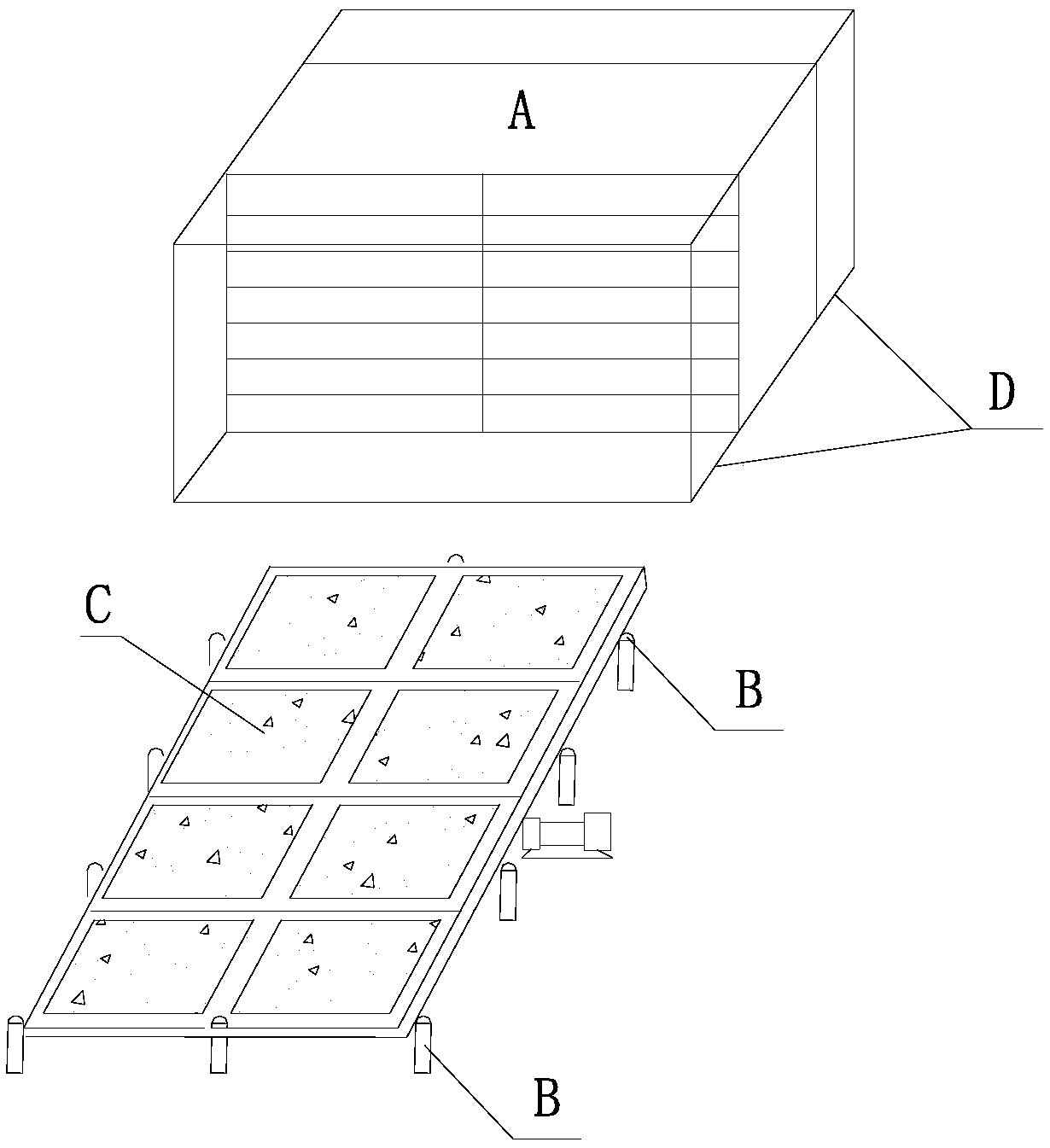

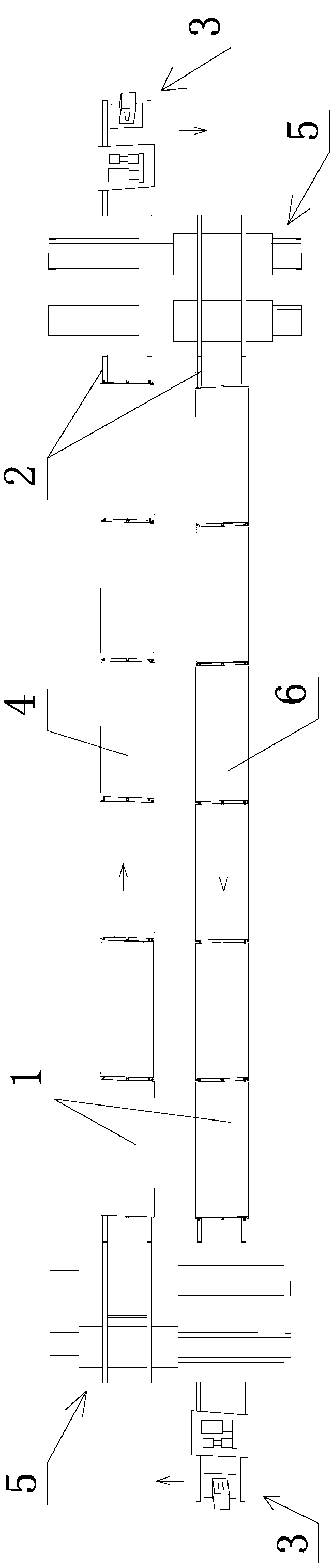

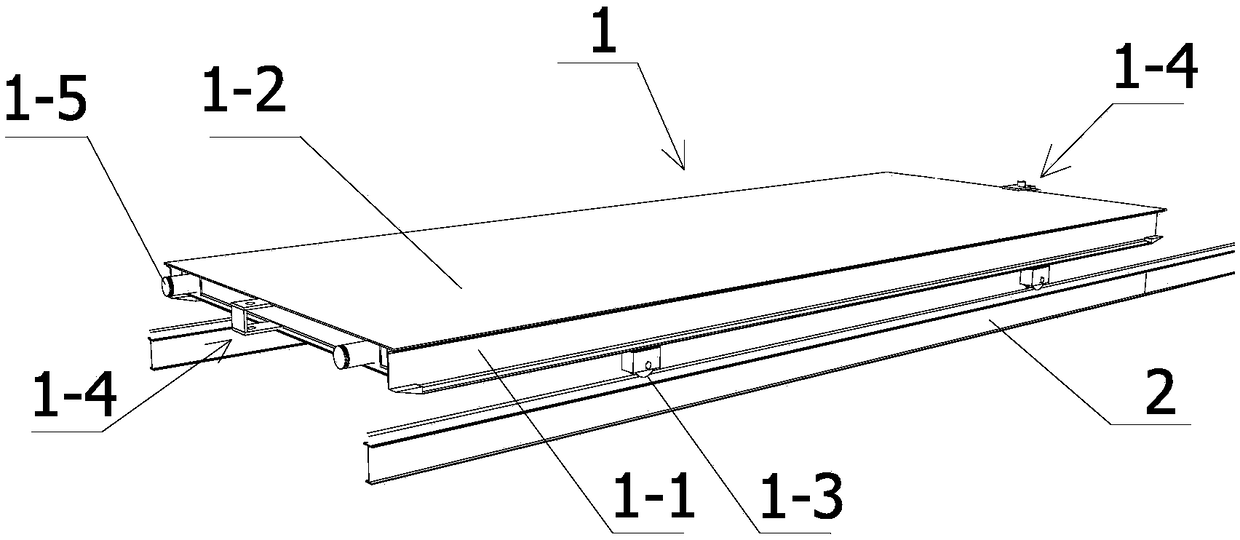

[0028] Such as figure 2 In the example shown, the closed-loop conveying system for the production line of prefabricated concrete wall panels of the present invention includes a table formwork vehicle 1 , a walking track 2 extending along a straight line, a traction device 3 and a ferry device 5 . The walking track 2 includes two groups arranged in parallel, one end of each group of walking track 2 is provided with a traction device 3, and two sets of ferry devices 5 are respectively located at both ends of the walking track 2, and a plurality of table formwork vehicles 1 follow the production process of prefabricated components Arranged in sequence along the walking track 2 and connected to each other to form a set of table form trains, which are pulled by the traction device 3 at one end of the set of walking tracks ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com