Lithium-ion battery non-aqueous electrolyte and lithium-ion battery

A non-aqueous electrolyte and lithium-ion battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low-temperature discharge performance, high-temperature performance, and low impedance, and achieve improved high-temperature cycle performance and good high-temperature performance, the effect of improving high-temperature storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

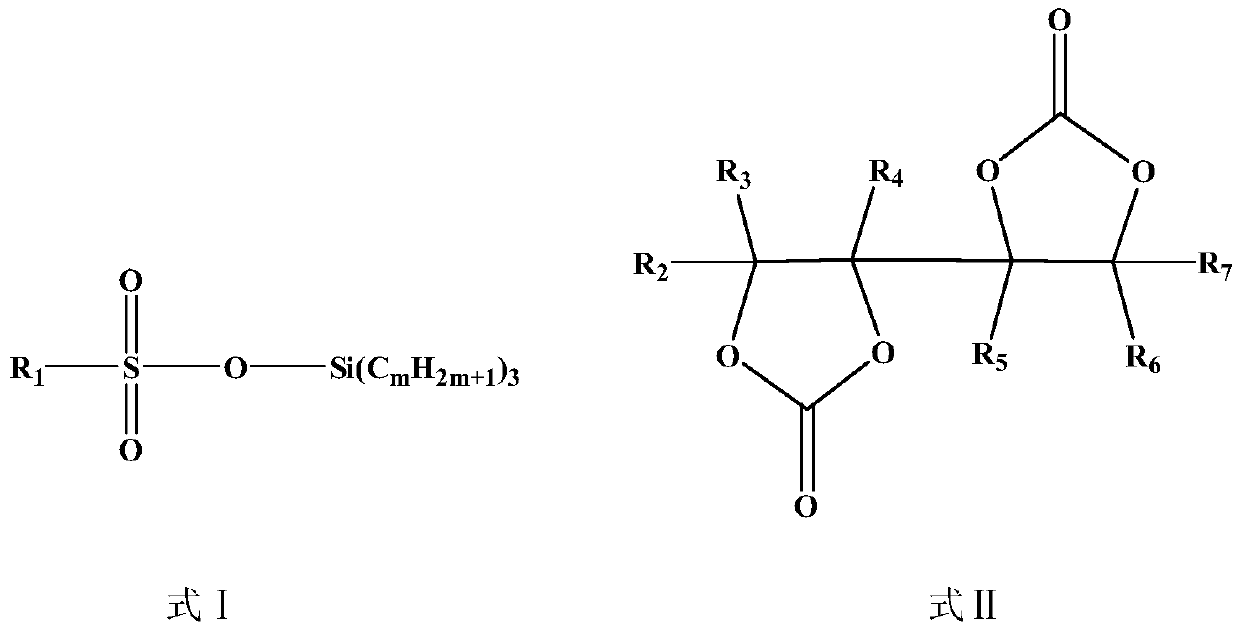

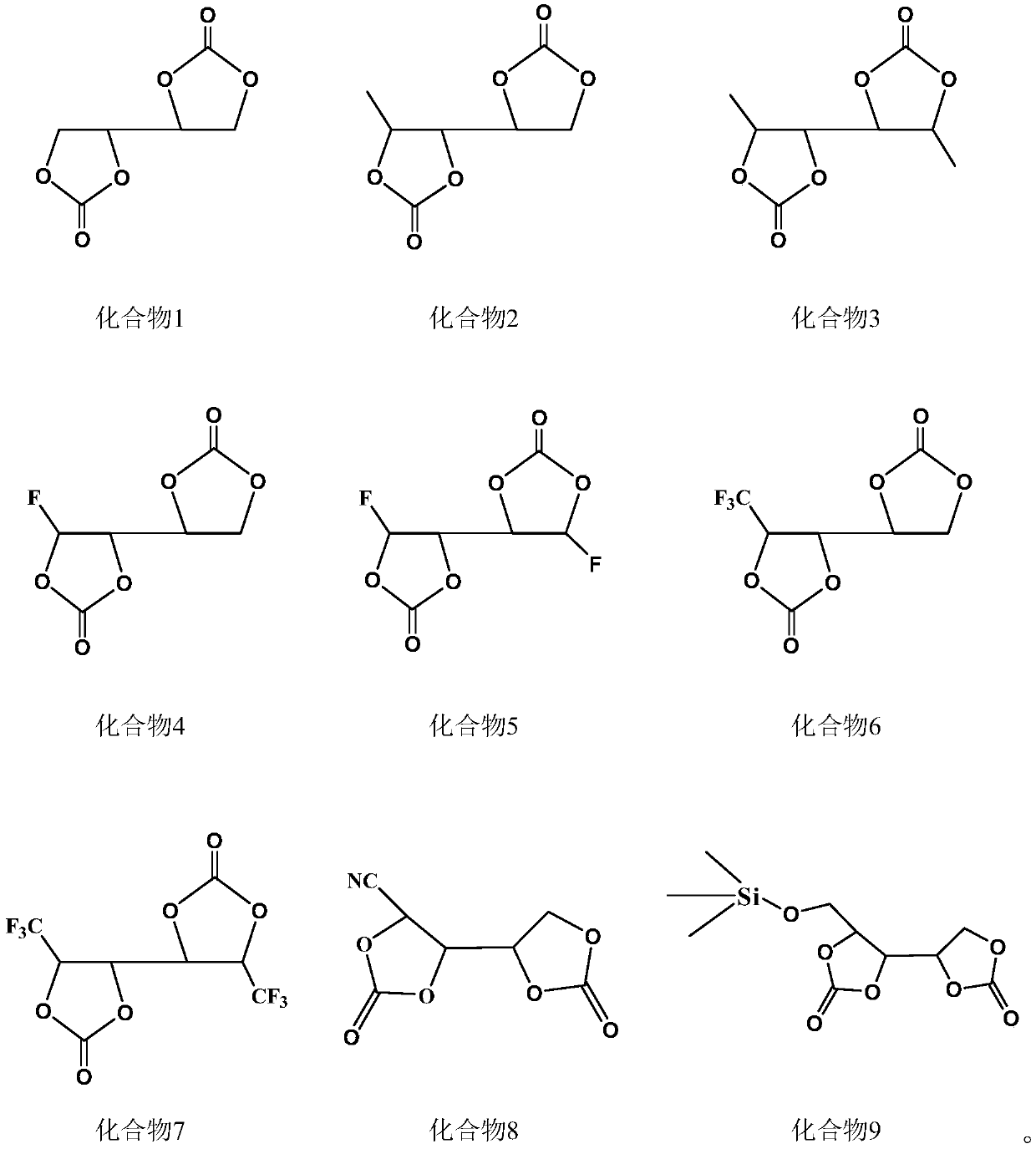

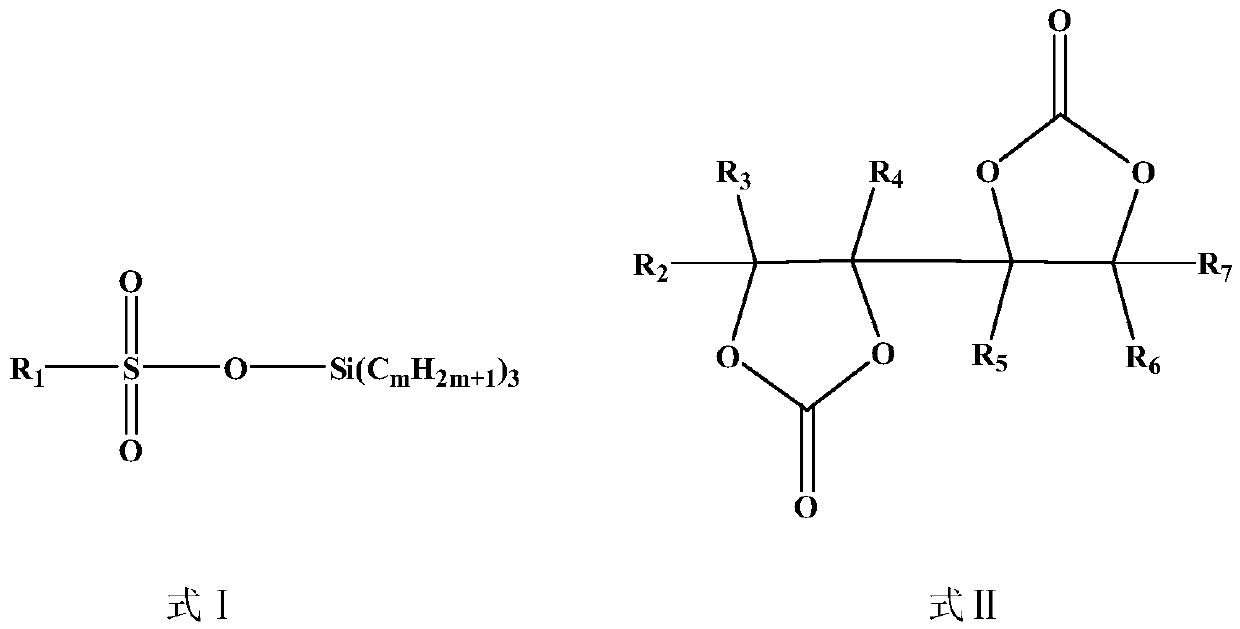

[0044] The preparation of fluorine-containing compound in compound B adopts corresponding carbonate and F 2 / N 2 After fluorination of the mixed gas, it can be purified by recrystallization or column chromatography. An example of its synthetic route is as follows:

[0045]

[0046] The cyano-containing compound in compound B is prepared by chlorinating the corresponding carbonate with sulfonyl chloride, then reacting with NaCN or KCN, and obtaining it through recrystallization or column chromatography purification. An example of its synthetic route is as follows:

[0047]

[0048] The trimethylsiloxy-containing compound in compound B is prepared by the substitution reaction between the corresponding hydroxycarbonate and nitrogen silane, and then purified by recrystallization or column chromatography. An example of its synthetic route is as follows:

[0049]

[0050] Further preferably, based on 100% of the total mass of the lithium-ion battery non-aqueous electrol...

Embodiment 1-16

[0066] Embodiment 1-16, comparative example 1-5

[0067] A 4.2V LiNi 0.5 co 0.2 mn 0.3 o 2 / artificial graphite battery, comprising a positive pole, a negative pole, a diaphragm arranged between the positive pole and the negative pole, and an electrolyte, wherein the electrolyte is a non-aqueous electrolyte, and the total amount of the non-aqueous electrolyte is The components and their contents in Examples 1-16 and Comparative Examples 1-5 are shown in Table 1 on a weight basis of 100%.

Embodiment 17-21, comparative example 6

[0069] A 4.4V LiCoO 2 / artificial graphite battery, comprising a positive pole, a negative pole, a diaphragm arranged between the positive pole and the negative pole, and an electrolyte, wherein the electrolyte is a non-aqueous electrolyte, and the total amount of the non-aqueous electrolyte is The weight is 100%, and the components and their contents in Examples 17-21 and Comparative Example 6 are shown in Table 2.

[0070] The LiNi of embodiment 1-16 of the present invention, comparative example 1-5 0.5 co0.2 mn 0.3 o 2 / artificial graphite battery, and the LiCoO of embodiment 17-21, comparative example 6 2 / Artificial graphite battery for performance testing, the test indicators and test methods are as follows:

[0071] (1) High-temperature cycle performance, which is reflected by testing the capacity retention rate after N cycles of 1C at 45°C. The specific method is: at 45°C, charge the formed battery to 4.2V with 1C constant current and constant voltage (Example 1- ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com