System and method for online monitoring of lubricating grease decay degree by infrared point laser transmitter

A technology of laser transmitter and grease, applied in scattering characteristic measurement, instrument, measurement device, etc., can solve the problem of low effective information rate, and achieve the effect of high information utilization rate, clear monitoring principle and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with accompanying drawing.

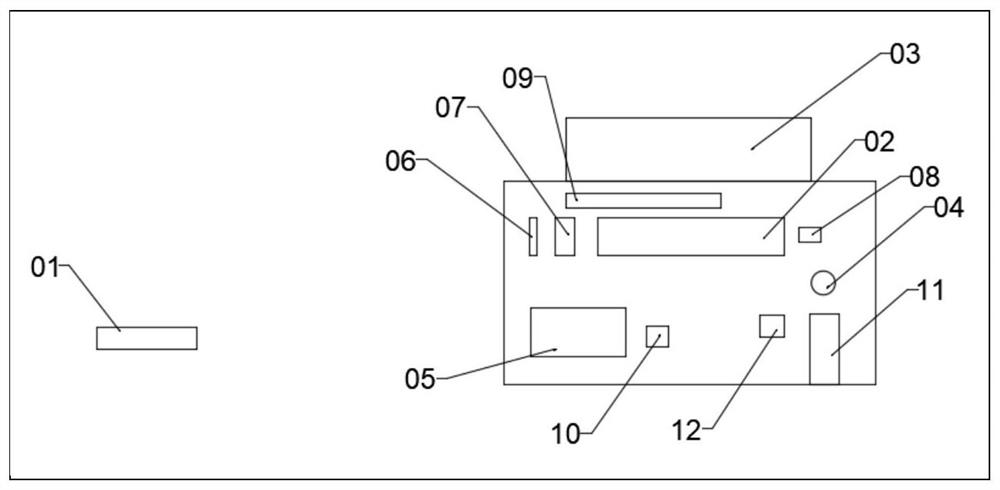

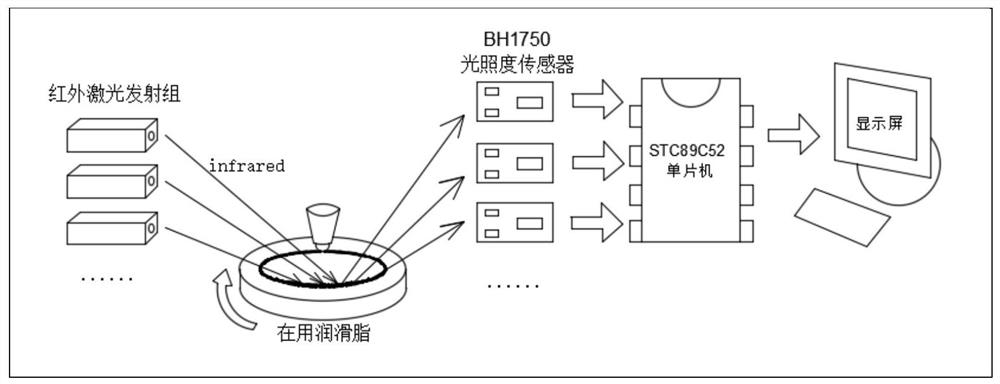

[0031] see figure 1 , Infrared point laser transmitter online monitoring grease decay degree system, including transmitters, receivers, processors and display devices.

[0032] The emission device is composed of a plurality of infrared point-like laser emitters 01 of different bands, and different bands correspond to the monitoring of different functional groups, such as the band 1200-1600cm -1 Corresponding to the monitoring of methyl groups, the wave band is 1600-2000cm -1 Corresponding to carbonyl monitoring, band 3200-3600cm -1 Corresponding hydroxyl monitoring;

[0033] The receiving device includes a BH1750 illuminance sensor 05 and a reset button 10. The BH1750 illuminance sensor 05 detects the light intensity of the received reflected light, and the reset button 10 is used to reset the illuminance data;

[0034] The processor includes STC89C52 single-chip microcomp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com