Shaft sleeve wear test device

A technology of wear test and shaft sleeve, which is applied in the direction of testing wear resistance, testing of mechanical components, testing of machine/structural components, etc. It can solve the problems that the sleeve wear test cannot simulate the real working state and the test data is inaccurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

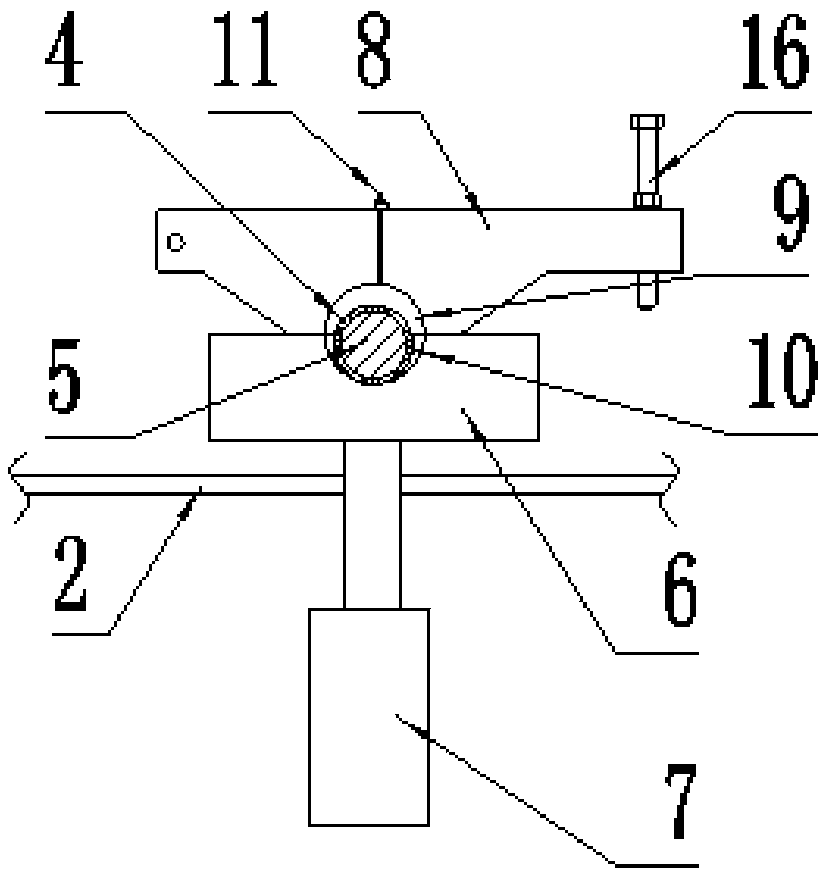

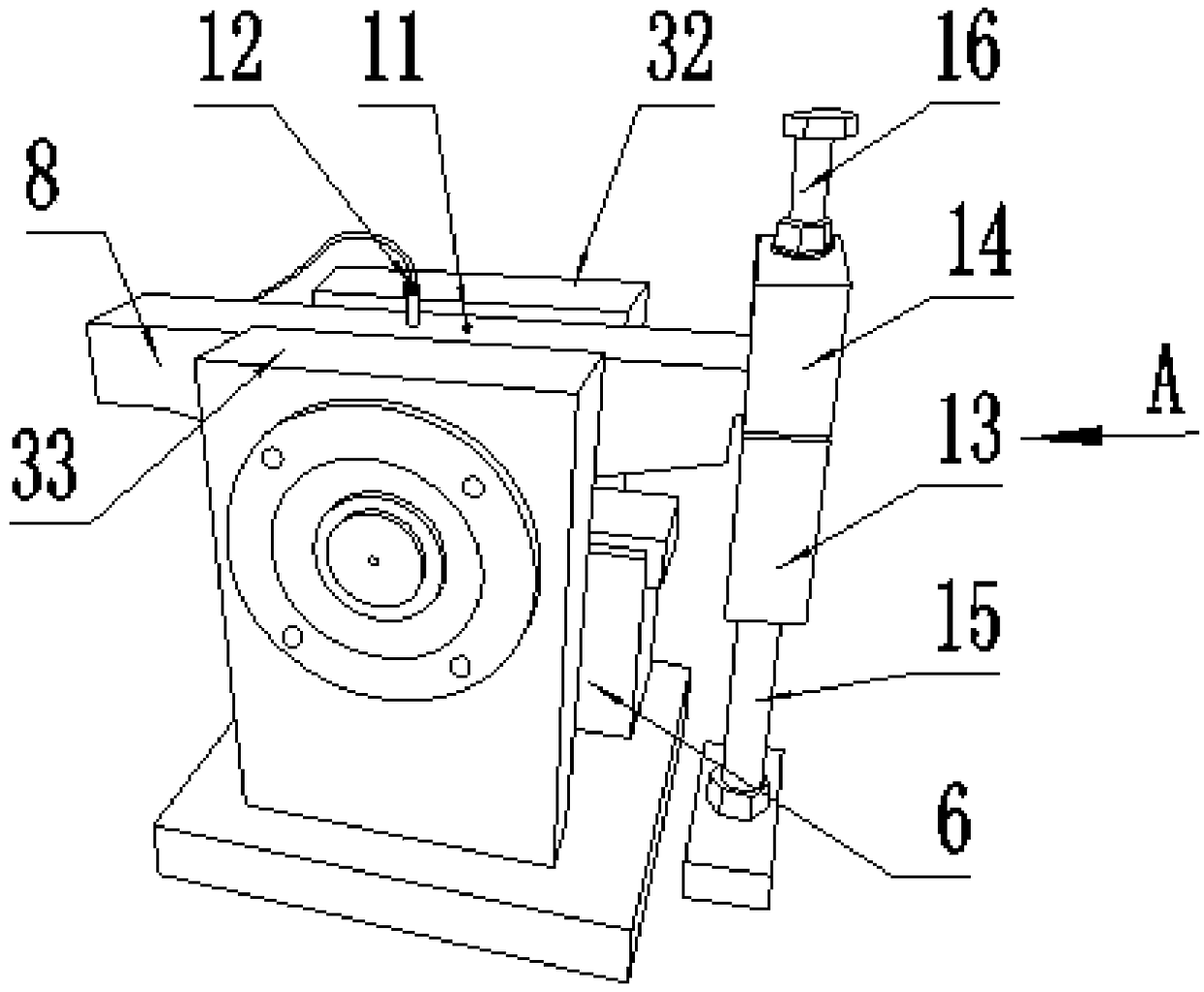

[0030] Further, see figure 1 , 2 , as a specific embodiment of the sleeve wear test equipment provided by the present invention, the frame 3 includes a first support base 31, a second support base 32 and a third support base 33, and one end of the transmission shaft 5 runs through The first support base 31 is connected with the yaw mechanism, the other end of the transmission shaft 5 is set through the second support base 32 and the third support base 33, and the sleeve 4 is arranged on the second support base 32 and the third support seat 33, the transmission shaft 5 is respectively rotatably matched with the first support seat 31, the second support seat 32 and the third support seat 33; the force applying mechanism is arranged on the shaft sleeve 4 below. Utilize the first supporting seat 31, the second supporting seat 32 and the third supporting seat 33 to play a supporting role to the transmission shaft, the transmission shaft drives it to make a yaw movement through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com