Stretching limiting spring

A technology of limit springs and limit strips, applied in the direction of springs, springs/shock absorbers, coil springs, etc., can solve the problems of springs with no elasticity and cannot be reset, and achieve the prevention of excessive stretching, simple structure, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

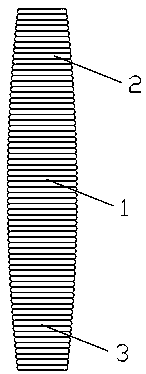

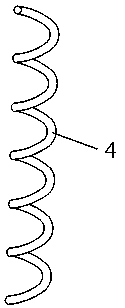

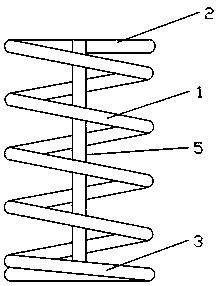

[0021] The embodiment of the present invention provides a stretch limit spring, see figure 1 , figure 2 The stretch limit spring includes a spring body 1, a spring base 2 extending from the spring body 1 to one side, a spring end body 3 extending from the spring body 1 to the other side, and a spring base 2 arranged at the end of the spring base 2. The limit strip 4 between the end of the spring end body 3.

[0022] Specifically, from the end of the spring base 2 to the direction of the spring body 1, the inner diameter gradually increases; from the end of the spring end body 3 to the direction of the spring body 1, the inner diameter gradually increases.

[0023] Specifically, the limit bar 4 is arranged between the end of the spring base 2 and the end of the spring end body 3, so that the spring cannot be stretched infinitely, so as to ensure that the spring body 1 will not be overstretched and cause the elastic force to disappear, and ensure that the spring can Stay stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com