Double-head claw pump rotor and its molded line

A rotor profile and claw pump technology, which is applied to rotary piston pumps, pumps, rotary piston/swing piston pump components, etc., can solve the problems of large wear, insufficient space for profile design parameters, and closed suction and exhaust Problems such as volume cannot be eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The present invention will be described in further detail below in conjunction with the accompanying drawings.

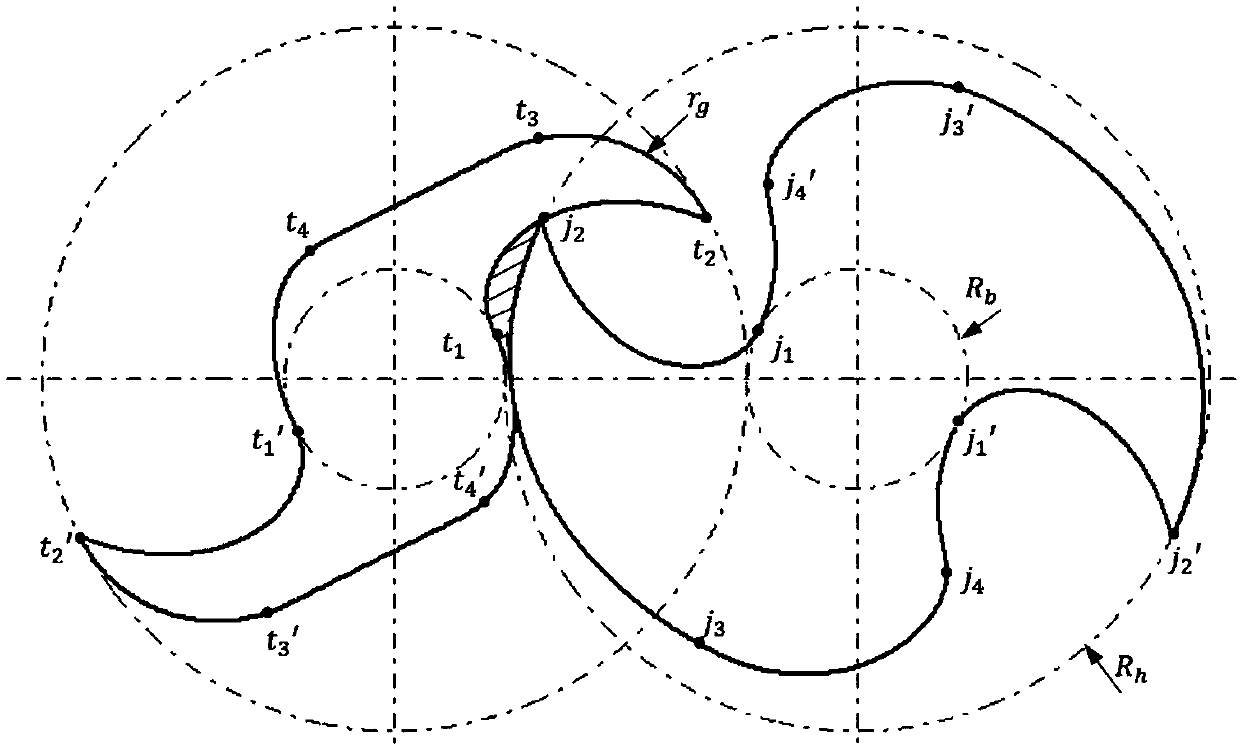

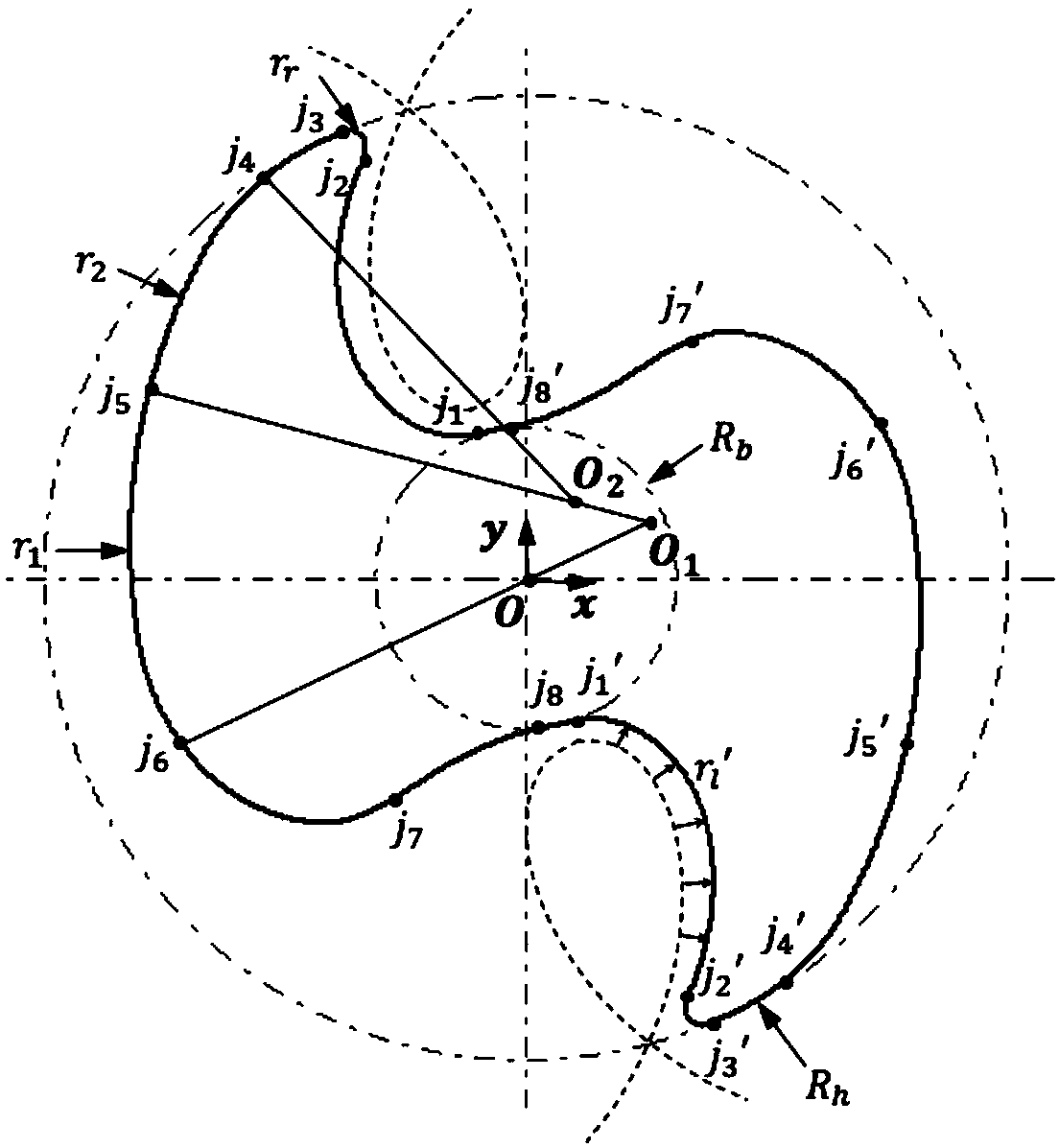

[0090] see figure 1 , in the original rotor profile design, the left rotor consists of cycloid segment t 1 t 2 , arc segment t 2 t 3 , straight line segment t 3 t 4 , special curve t 4 t 1 ’, and with the curve t 1 t 2 t 3 t 4 t 1 'centrosymmetric curve t 1 't2 't 3 't 4 't 1 composition. The right rotor is defined by the cycloid segment j 1 j 2 , special curve t 4 t 1 'Conjugate meshing curve j 2 j 3 , straight line segment t 3 t 4 The conjugate meshing curve j of 3 j 4 , arc segment t 2 t 3 The conjugate meshing curve j 4 j 1 ’ and with curve j 1 j 2 j 3 j 4 j 1 'centrosymmetric curve j 1 'j 2 'j 3 'j 4 'j 1 composition. Among them, the special curve t 4 t 1 The selection of ′ is different, as long as the curve is continuous and the first-order smoothness is satisfied. The type line is defined by the parameter R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com