Creep-resistant polypropylene composite material

A technology of composite materials and polypropylene, which is applied in the field of processing and modification of polymer materials, can solve the problems of loose assembly of functional parts, poor creep resistance, and large assembly gaps, etc., to increase thermal deformation temperature and improve creep resistance performance, effect of small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

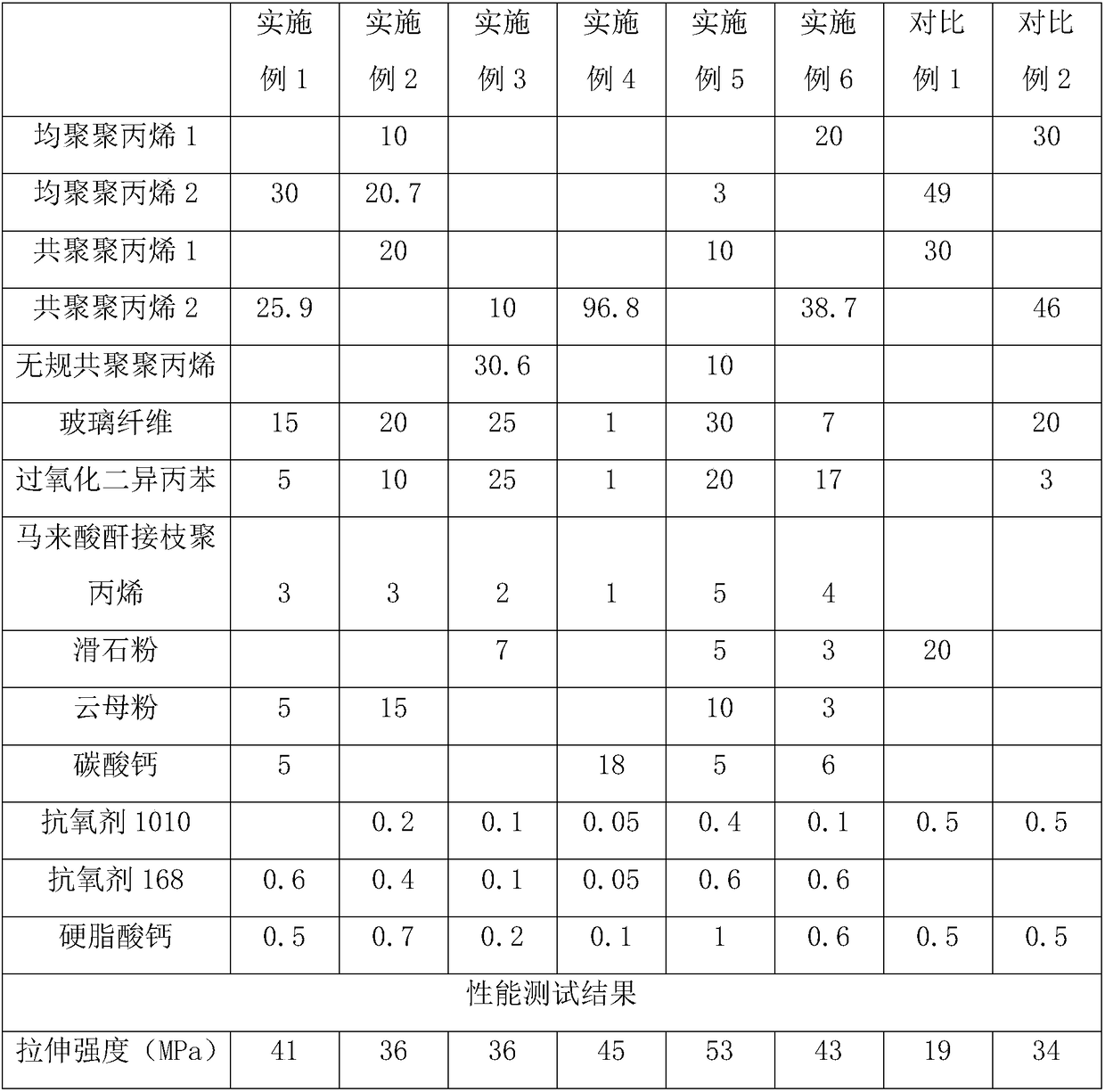

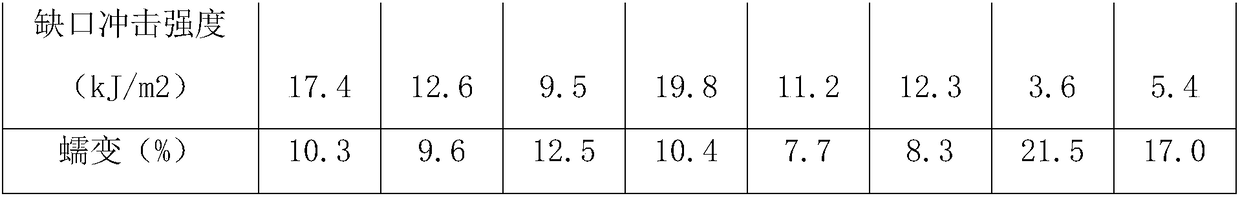

[0021] The present invention is described in detail in conjunction with specific examples. The raw materials selected in the following specific examples are as follows, but the raw materials selected for each component in this application are not limited to the raw materials of the following specifications.

[0022] Homopolypropylene 1 (homopolymer PP1): melt flow rate is 60g / 10min (230℃ / 2.16kg), density is 0.9g / cm 3 .

[0023] Homopolypropylene 2 (homopolymer PP2): melt flow rate is 20g / 10min (230℃ / 2.16kg), density is 0.9g / cm 3 .

[0024] Copolymerized polypropylene 1 (homopolymerized PP1): melt flow rate is 15g / 10min (230℃ / 2.16kg), density is 0.89g / cm 3 .

[0025] Copolymerized polypropylene 2 (homopolymerized PP2): melt flow rate is 40g / 10min (230℃ / 2.16kg), density is 0.89g / cm 3 .

[0026] Random copolymerized polypropylene: Melt flow rate (MFR) is 5g / 10min (230°C / 2.16kg).

[0027] Glass fiber: Chopped glass fiber with a diameter of 5-20 microns, produced by Shandong ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com