A kind of acid soluble cement slurry and its preparation method and application

A cement slurry and acid-soluble technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor fluidity, unsatisfactory magnesia cement slurry, and incomplete dissolution of cement chips, so as to slow down thickening. Faster curing and hardening speed, long thickening time, and the effect of reducing water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] In a second aspect, the embodiments of the present invention also provide a method for preparing acid-soluble cement slurry, the preparation method comprising the following steps:

[0052] According to the parts by weight of each component, add water, magnesium chloride, retarder, fluid loss reducer, and optional sodium tripolyphosphate into the first batching tank, and stir to obtain a mixed solution; add Dead burnt magnesia, magnesium carbonate, calcium carbonate, and optional superfine silicon dioxide and ammonium phosphate are stirred to obtain a dry mixture; in the third liquid mixing tank, the mixed solution is stirred and reacted with the dry mixture to obtain cement pulp.

[0053] The above-mentioned preparation method is simple, and it is convenient to prepare cement slurry whose fluidity and thickening time meet the requirements of cementing construction, and can be dissolved in acid after the cement slurry is hardened, which is convenient for dredging perfora...

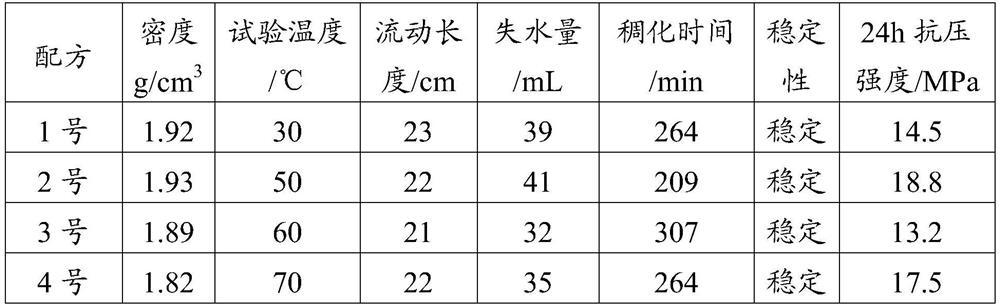

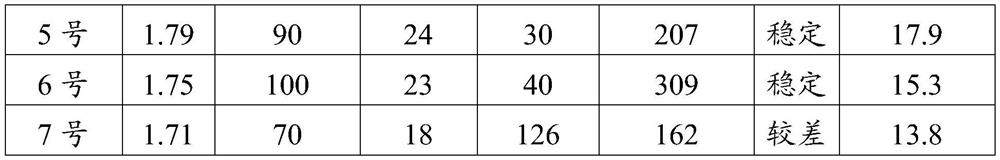

Embodiment 1

[0062] This embodiment provides an acid-soluble cement slurry, which is prepared by the following method: according to the parts by weight of each component, add 0.38 parts of water, 0.5 parts of magnesium chloride, and 0.01 part of organic phosphoric acid in the first batching tank / maleic anhydride copolymer, 0.03 part of acrylic acid / 2-acrylamide-2-methylpropanesulfonic acid / polyvinylpyrrolidone copolymer, 0.01 part of sodium tripolyphosphate, and stirred for 60 minutes to obtain a mixed solution. Add 1 part of dead burnt magnesia, 0.1 part of magnesium carbonate, 0.3 part of calcium carbonate, 0.006 part of ultrafine silica with a particle size of 3 μm, and 0.02 part of ammonium phosphate into the second liquid mixing tank, and stir for 50 minutes to obtain a dry mixture. Finally, in the third liquid mixing tank, the mixed solution and the dry mix are mixed and reacted to obtain the cement slurry provided in Example 1.

Embodiment 2

[0064] This embodiment provides an acid-soluble cement slurry, which is prepared by the following method: according to the parts by weight of each component, add 0.36 parts of water, 0.6 parts of magnesium chloride, and 0.03 parts of organic phosphoric acid in the first batching tank / maleic anhydride copolymer, 0.04 part of acrylic acid / 2-acrylamide-2-methylpropanesulfonic acid / polyvinylpyrrolidone copolymer, 0.03 part of sodium tripolyphosphate, and stirred for 80 minutes to obtain a mixed solution. Add 1 part of dead burnt magnesia, 0.08 part of magnesium carbonate, 0.4 part of calcium carbonate, 0.01 part of ultrafine silica with a particle size of 4 μm, and 0.03 part of ammonium phosphate into the second liquid mixing tank, and stir for 40 minutes to obtain a dry mixture. Finally, in the third liquid mixing tank, the mixed solution is stirred and reacted with the dry mix to obtain the cement slurry provided in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com