Double protection device for preventing skip bucket bin door from being automatically opened

A double protection, skip bin technology, applied in transportation and packaging, lifting equipment in mines, elevators, etc., can solve problems such as low safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

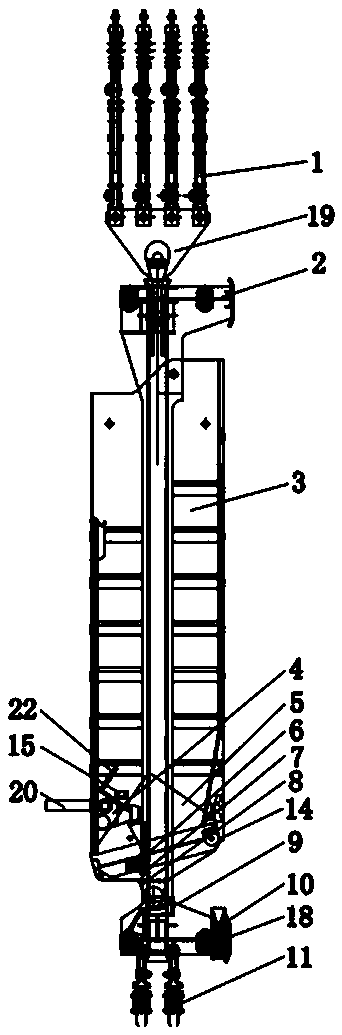

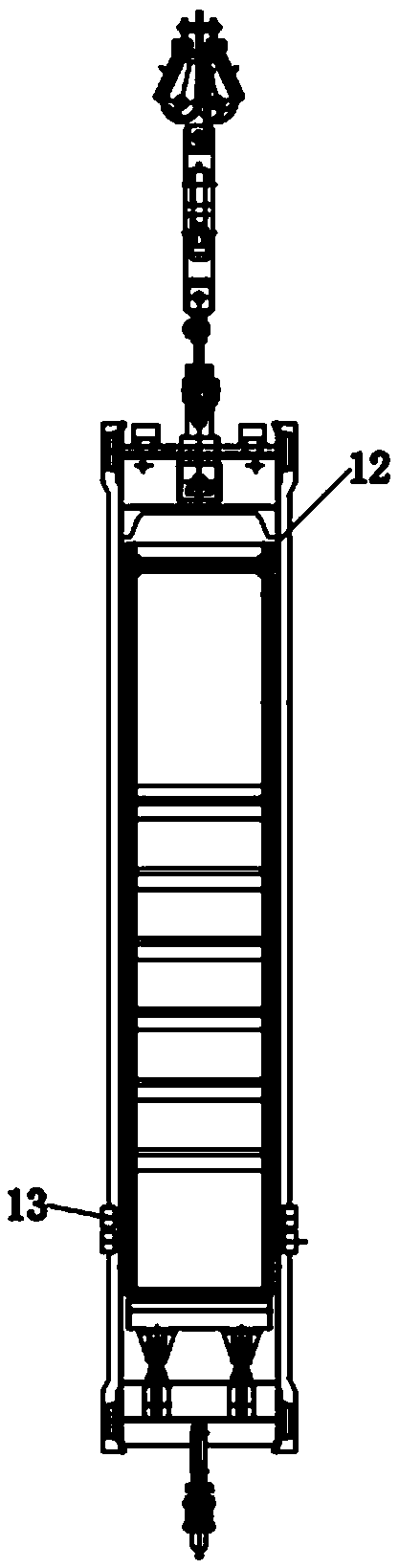

[0027] Please refer to Figure 1-5 , in the first embodiment of the present invention, the double protection device that prevents the skip door from opening by itself includes: a frame 2; a cube suspension device 19, the bottom of the cube suspension device 19 is arranged on the top of the frame 2; Automatic balance suspension device 1, the bottom of described tension automatic balance suspension device 1 is arranged on the top of described cube suspension device 19; Bucket box 3, the back side of described bucket box 3 is arranged on the surface of described framework 2; Movable bucket bottom 5. The back of the movable bucket bottom 5 is set at the bottom of the surface of the frame 2; the supporting wheel 8, the axis of the supporting wheel 8 is set at the bottom of the movable bucket bottom 5; the curved track of the supporting wheel 9 , the curved track 9 of the supporting roller is arranged on the bottom of the surface of the frame 2, and the curved track 9 of the support...

no. 2 example

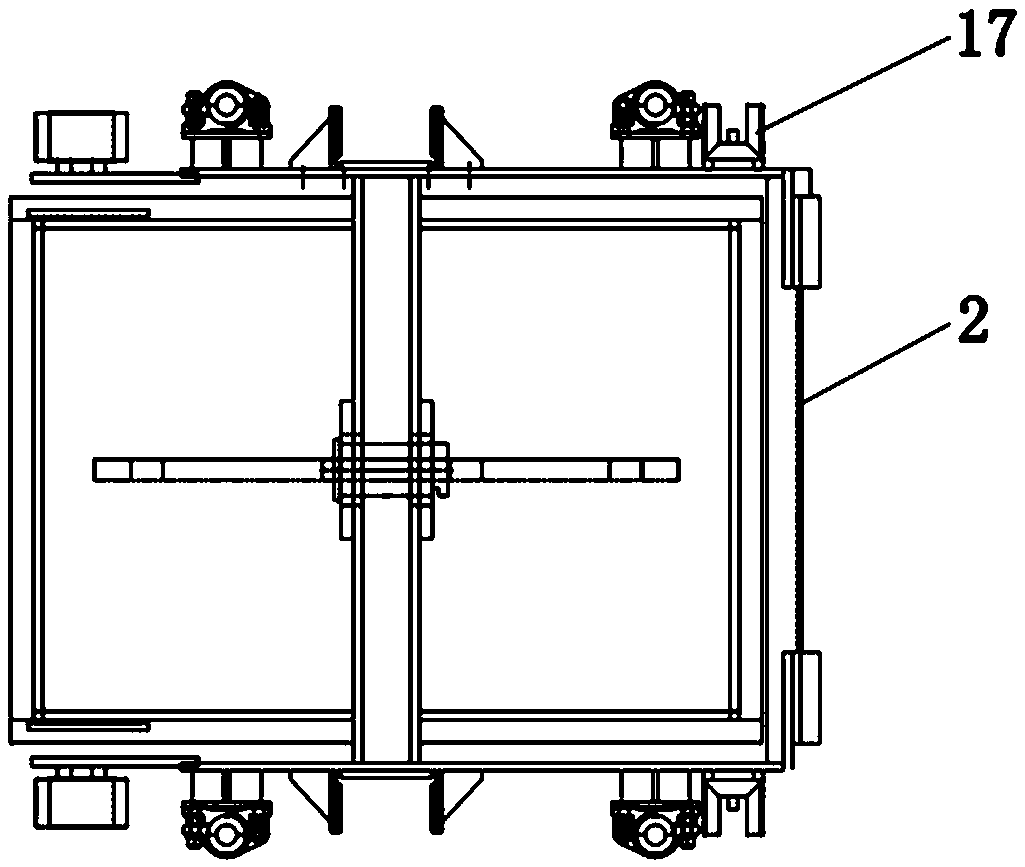

[0037] Please refer to Figure 6-7 , based on the double protection device for preventing the self-opening of the skip bin door provided by the first embodiment of the present invention, the difference in the double protection device for preventing the self-opening of the skip bin door provided by the second embodiment of the present invention is that The right side of the frame 2 is fixedly connected with a fixed frame 23, the surface of the bucket box 3 is fixedly connected with a fixed block 28, and the bottom of the inner wall of the fixed frame 23 is fixedly connected with a motor 24, and the motor 24 is a three-phase asynchronous AC motor , and connected to an external power supply through an external power cord, the output shaft of the motor 24 is fixedly connected with a screw 25, the surface of the screw 25 is threaded with a threaded block 26, one side of the threaded block 26 is connected to the One side of the inner wall of the fixed frame 23 is slidably connected....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com