Straight steel bar storage and transportation rack

A technology for transport racks and steel bars, which is applied in the field of storage transport racks, can solve the problems of no distinction between steel bar diameters, chaotic factory management, time-consuming and labor-intensive material collection, etc., to achieve the effects of reducing manual operations, solving messy stacking, and neat management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

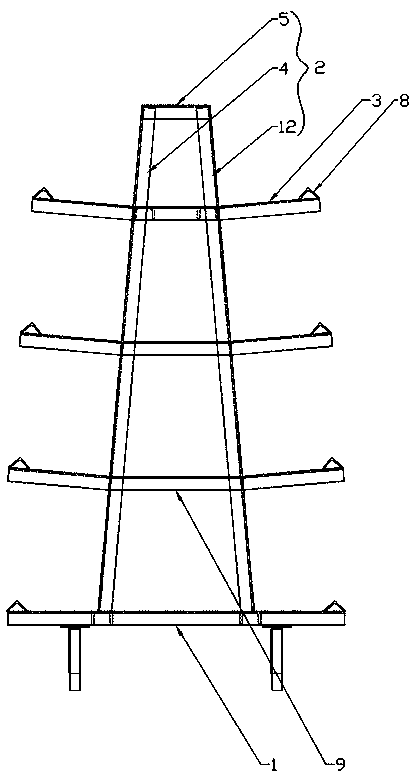

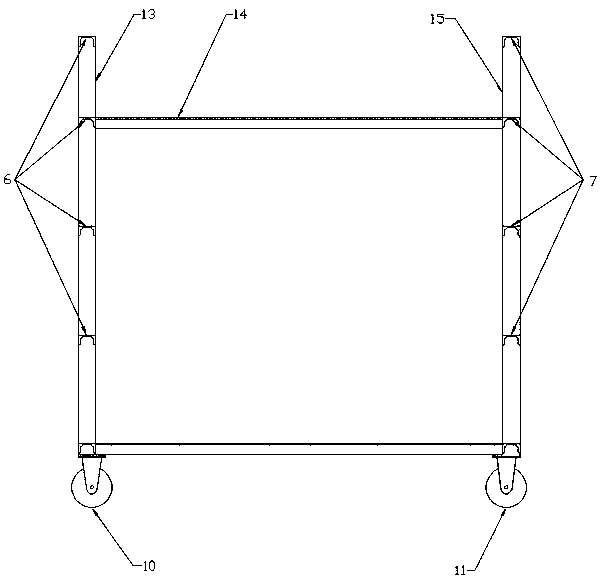

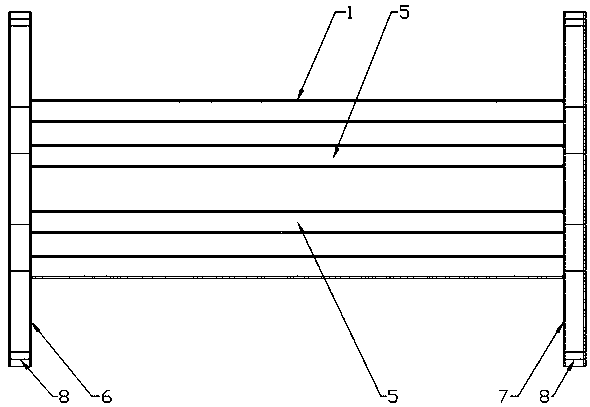

[0022] Such as Figure 1 to Figure 3 As shown, in this embodiment, the present invention includes an underframe structure 1 and a vertical support frame 2 arranged on the underframe structure 1, and the front and rear sides of the vertical support frame 2 are arranged in parallel from top to bottom. Several groups of support arms 3 are arranged, and the support arms 3 are arranged inclined upwards.

[0023] In this embodiment, the vertical support frame 2 includes a front frame structure 12, a rear frame structure 4 and an upper connection structure 5, and the bottom of the front frame structure 12 and the bottom of the rear frame structure 4 are connected to the The underframe structure 1 is connected, and the upper part of the front frame structure 12 and the upper part of the rear frame structure 4 are connected through the upper connection structure 5 .

[0024] In this embodiment, the support arm 3 includes a left arm 6 and a right arm 7, and the left arm 6 and the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com