Non-contact transmission indicating mechanism for screw pitch feedback of ship controllable-pitch propeller

A non-contact, indicating mechanism technology, applied in ship propulsion, ship parts, ship construction, etc., can solve problems such as structural wear and tear, achieve long service life, convenient installation and debugging, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

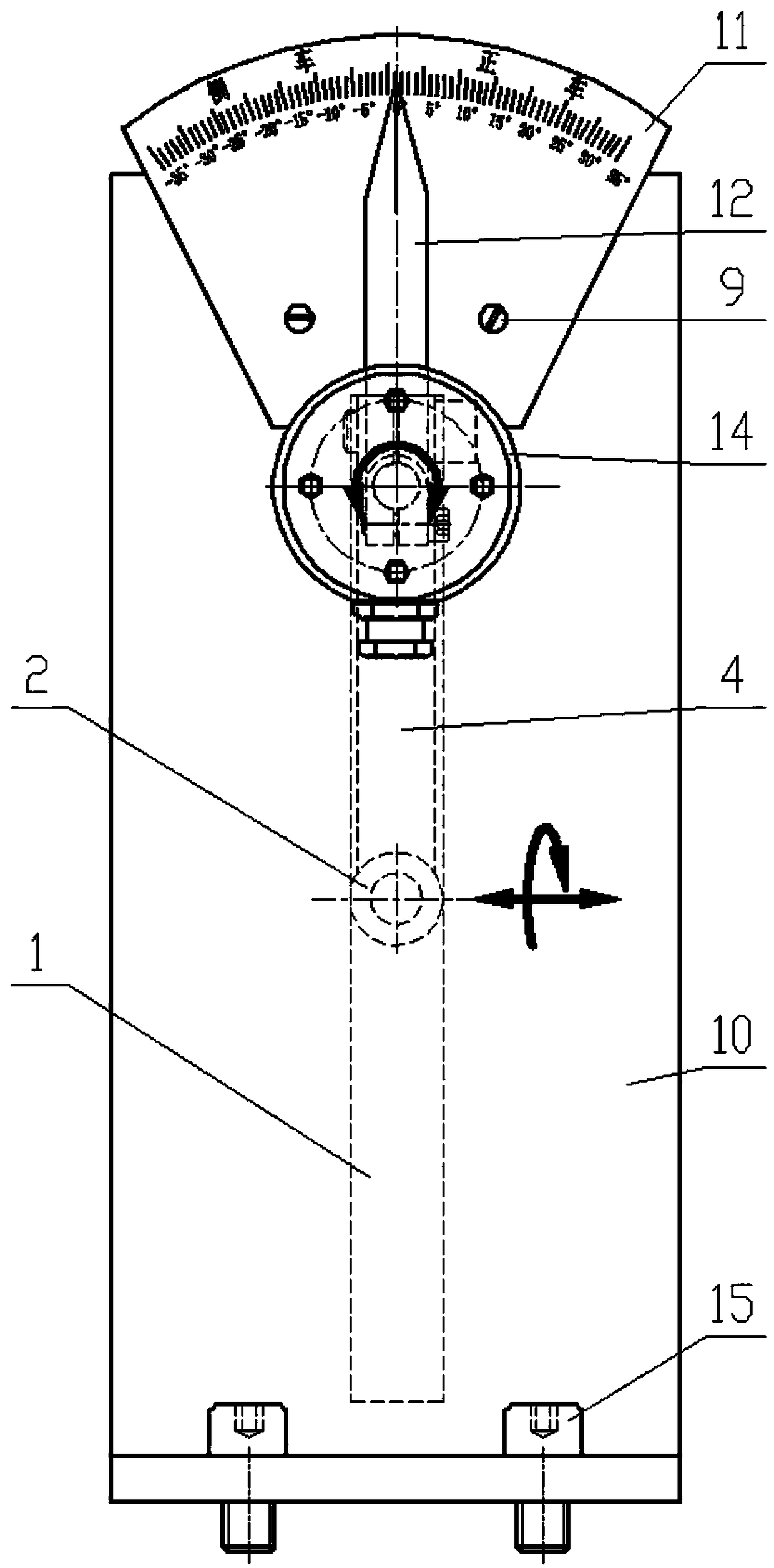

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

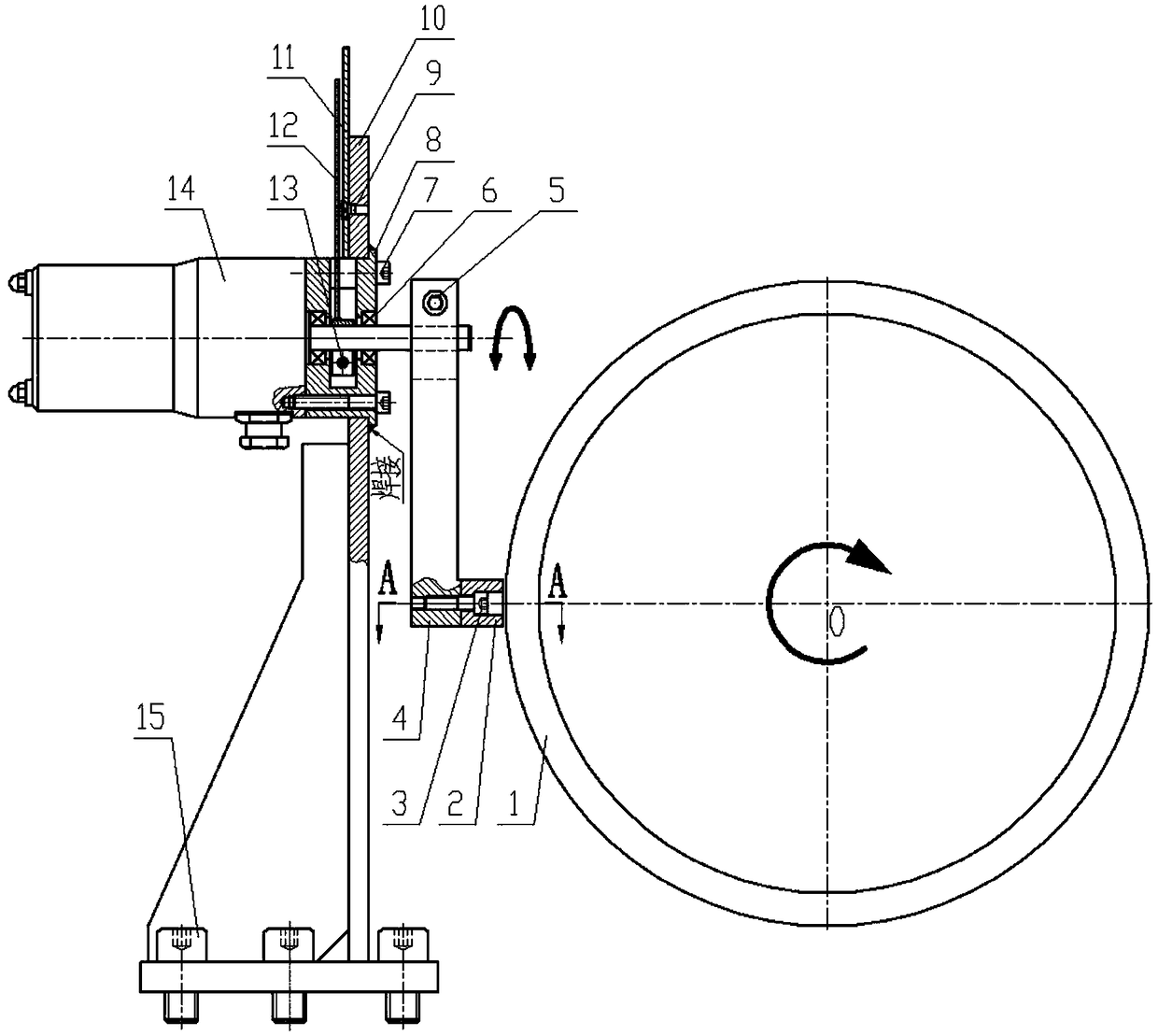

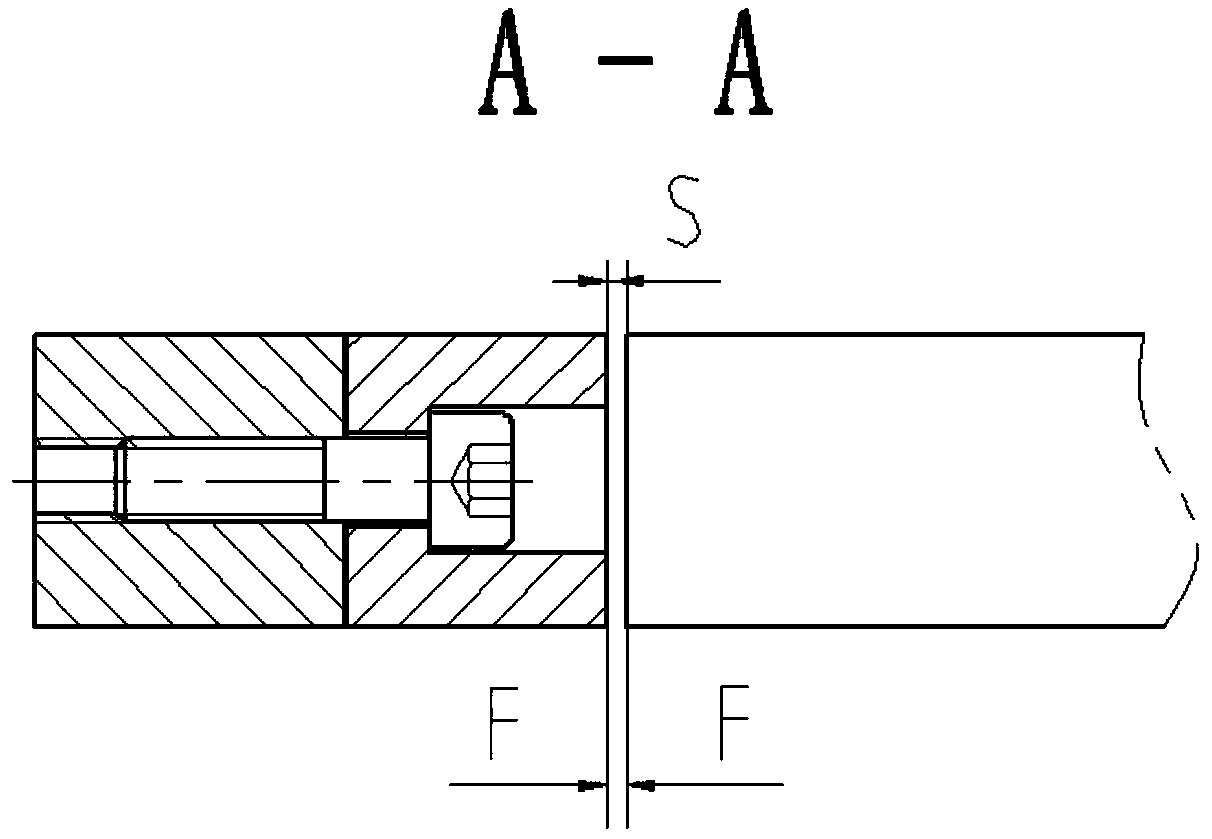

[0017] Please refer to the attached Figures 1 to 5 , the embodiment of the present invention includes:

[0018] A non-contact transmission indicating mechanism for the pitch feedback of ship controllable propellers, such as figure 1 with figure 2 As shown, the feedback loop 1 is installed on the pitch control propeller shaft system, and is rigidly connected with the axially movable parts inside the shaft system. The axial moving parts inside the system make translational movement in the axial direction.

[0019] The non-contact transmission indicating mechanism fixes the mounting support 10 on the hull plate through bolts 15. When installing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com