Sea horse type vibration damper assembling and disassembling device and method

An anti-vibration hammer and hippocampus technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of hidden dangers, manual disassembly, power failure, etc., to ensure safety, reliability, convenient operation, and space requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

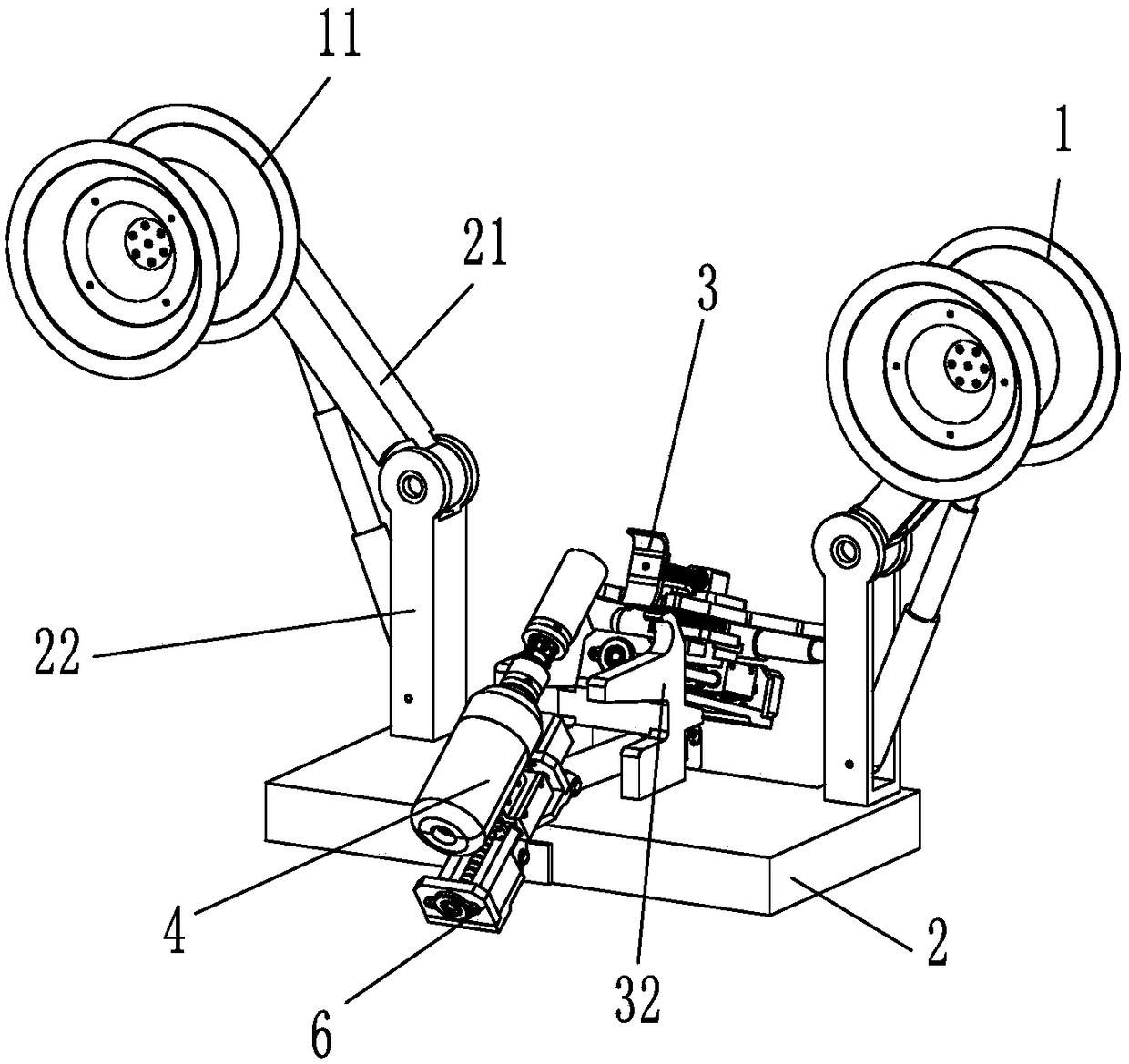

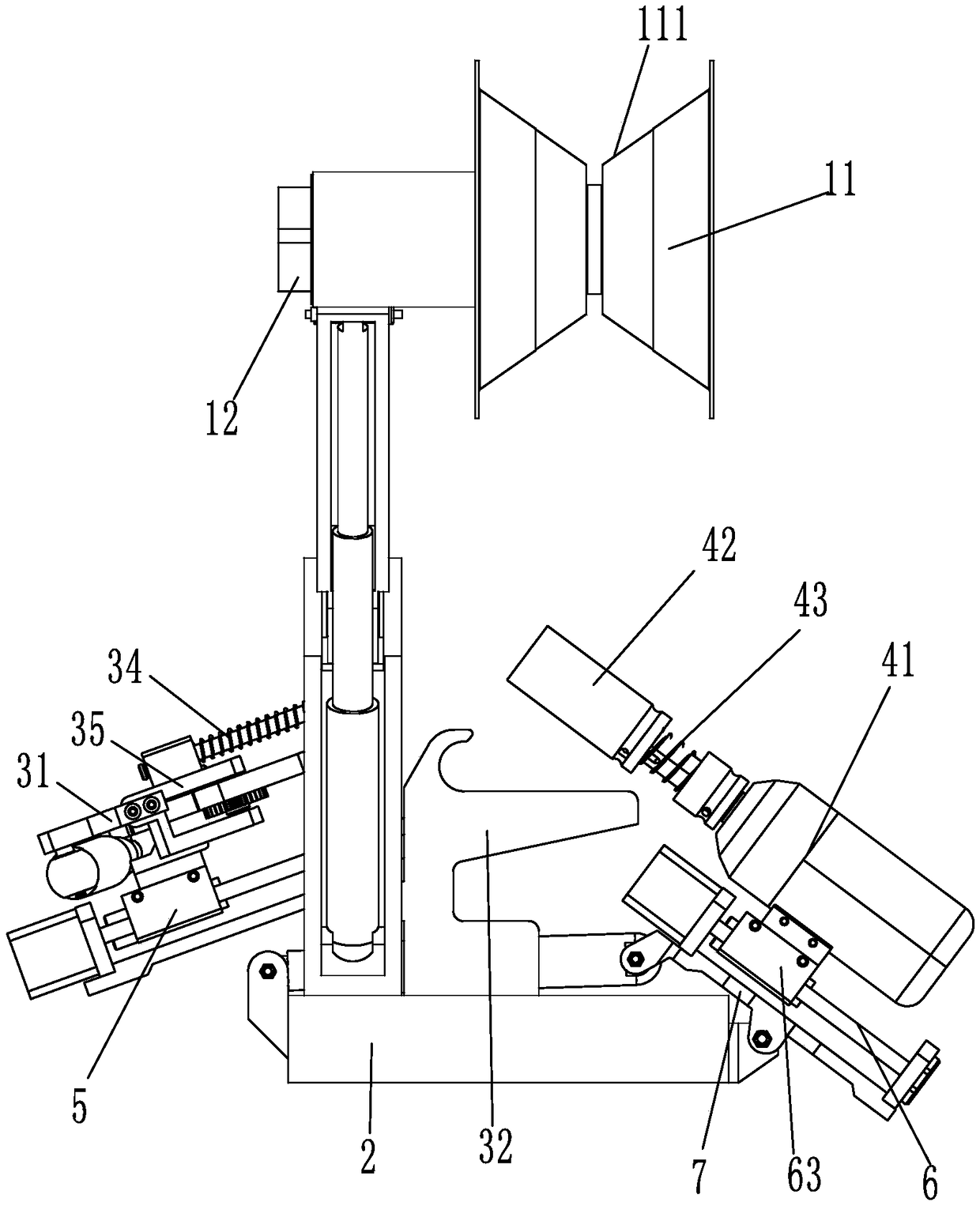

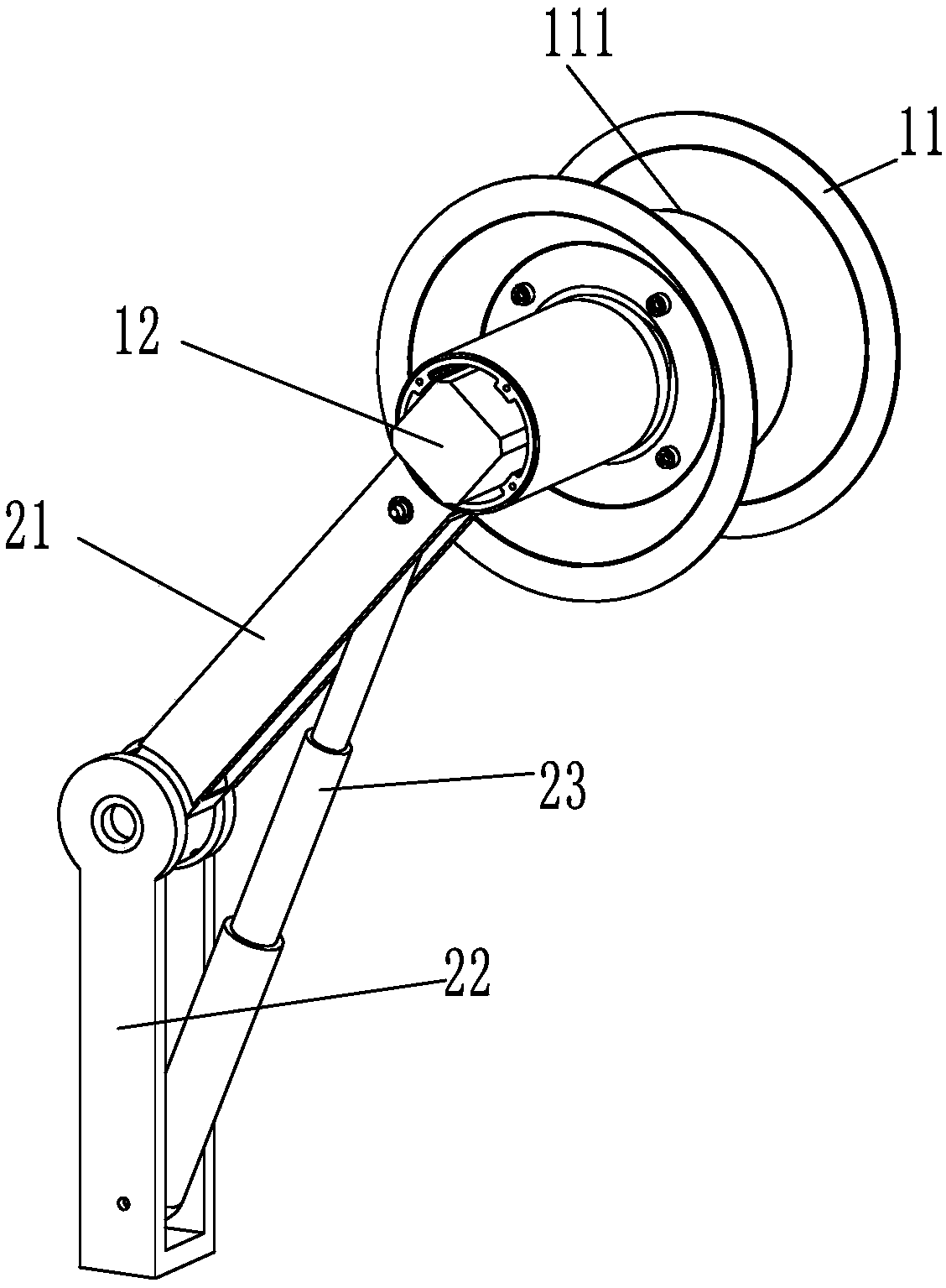

[0034] figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Among them, a seahorse type anti-vibration hammer disassembly device, including a clamping and positioning component 3, a wrench component 4, a walking and lifting component 1, and a base 2; the clamping and positioning component 3 and the wrench component 4 are located on the base 2, and the clamping and positioning The assembly 3 and the wrench assembly 4 are arranged oppositely. The clamping and positioning assembly 3 includes a clamping positioning seat 32 and two clamping jaws 31 that can be expanded and tightened. The clamping positioning base 32 is used to position the anti-vibration hammer, and the clamping jaws 31 For the clamping and positioning of the anti-vibration hammer; the side of the clamping positioning seat 32 facing the wrench assembly 4 is provided with tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com