Stator assembly and hybrid excitation motor

A component and stator technology, applied in the direction of electric components, windings, electrical components, etc., can solve the problem that the motor cannot play the best performance, and achieve the effect of improving the weak magnetic performance, reducing the amount of materials, and reducing the volume of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

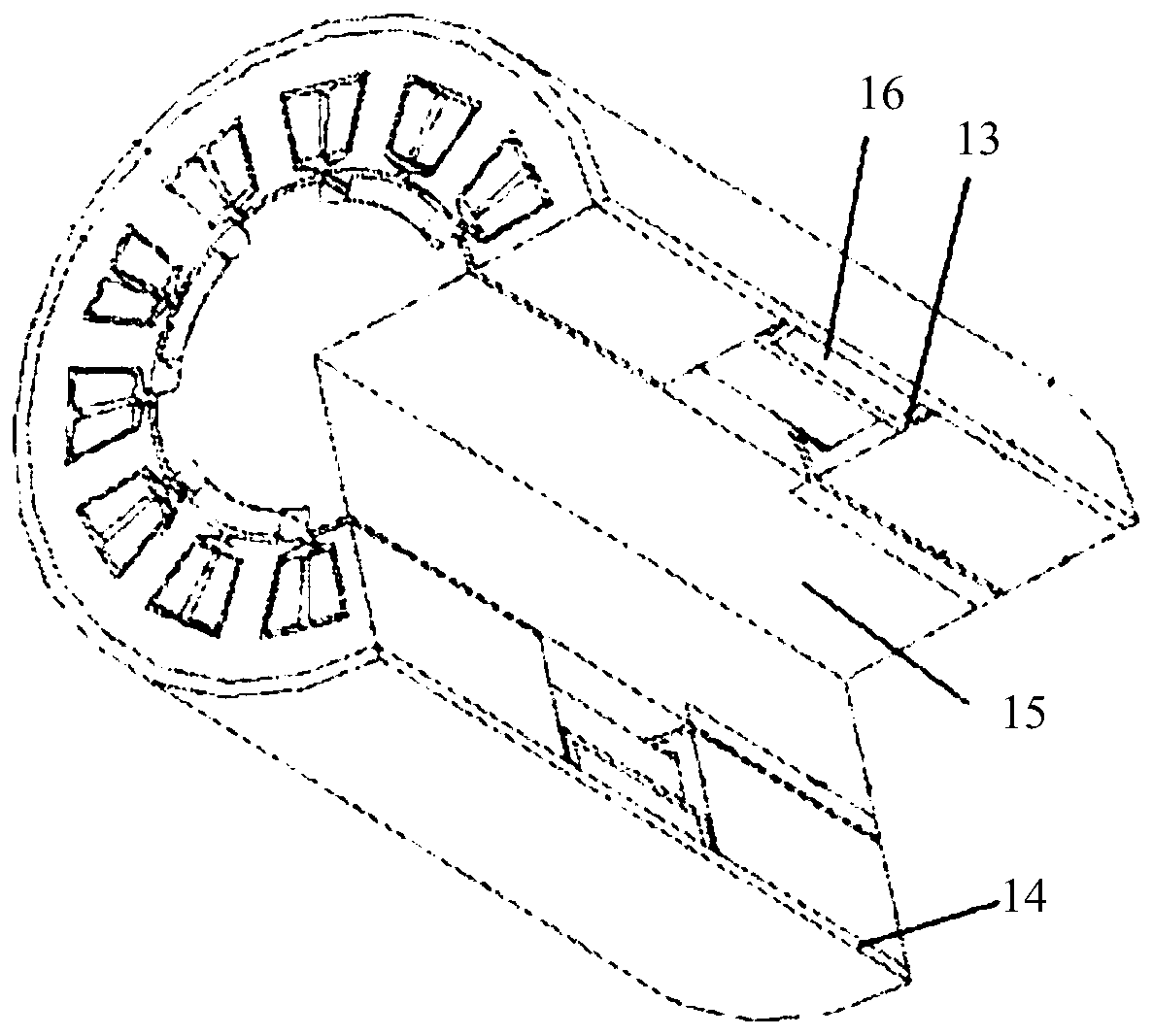

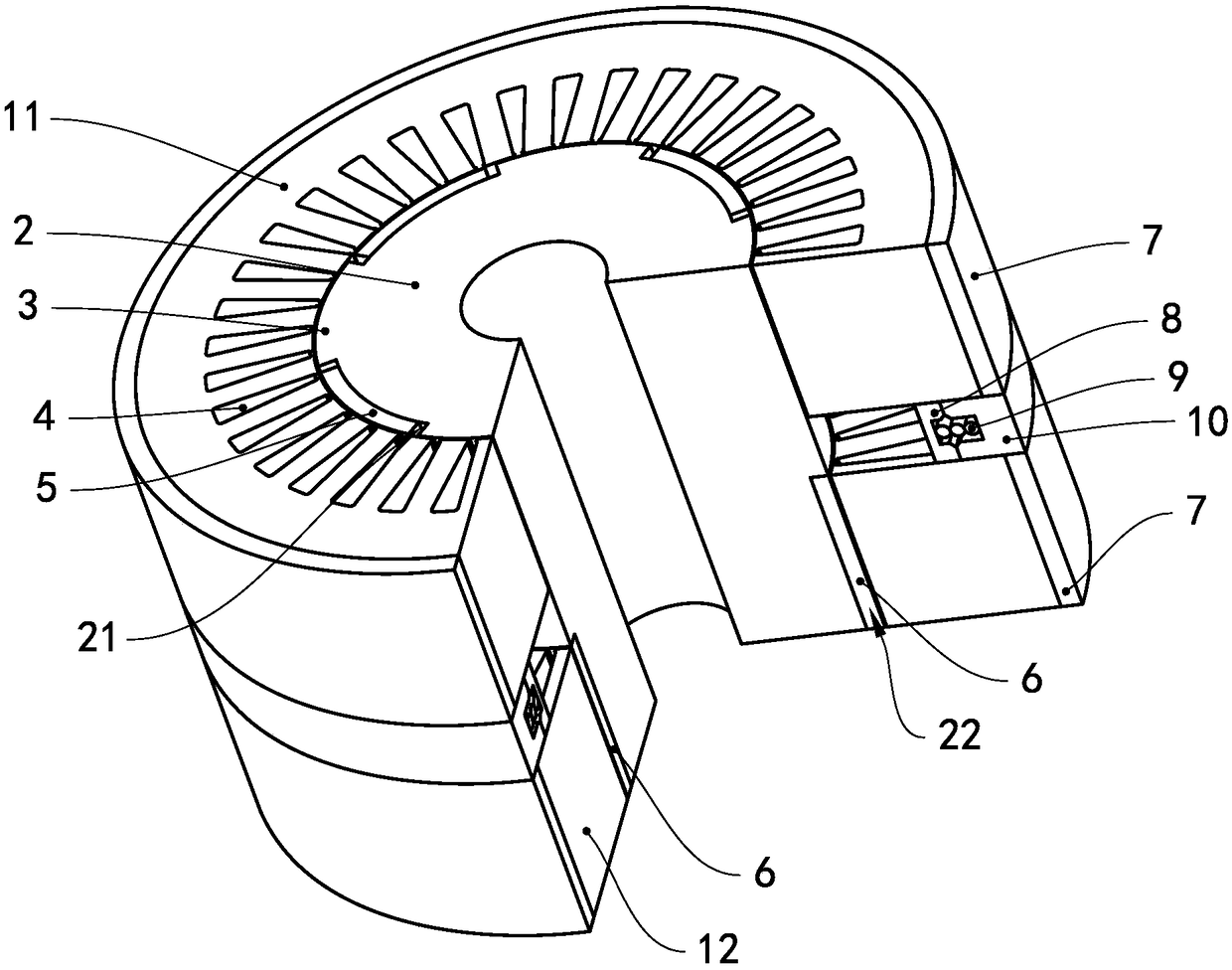

[0026] Stator Assembly and Hybrid Excitation Motor First Embodiment

[0027] see image 3 and Figure 4 , the hybrid excitation motor of this embodiment can be applied to new energy vehicles. The hybrid excitation motor includes a rotor assembly and a stator assembly. The stator core 11, stator core 12, winding ring 8, magnetic permeable bracket 10, field winding 9, magnetic permeable ring 7, armature winding 4 and, the size and groove type of stator core 11 and stator core 12 They are exactly the same, and the stator core 11 and the stator core 12 are arranged along the axial direction of the stator assembly. Armature winding 4 is wound on stator core 11 and stator core 12 . The rotor assembly passes through the stator core 11 and the stator core 12 in sequence.

[0028] The strength of the magnetically permeable support 10 and the winding ring 8 is higher than that of the stator core 11 and the stator core 12 . The magnetically conductive support 10 is sleeved outside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com