Flexible microwave directional coupler with controllable coupling degree

A directional coupler and coupler technology, applied in the field of radio frequency and microwave, can solve the problems of inflexibility of couplers, inflexible and simple coupling design, etc., and achieve the effect of good bendability, flexible design, and reliable and flexible characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, a flexible microwave directional coupler working at 6-10 GHz to realize strong coupling.

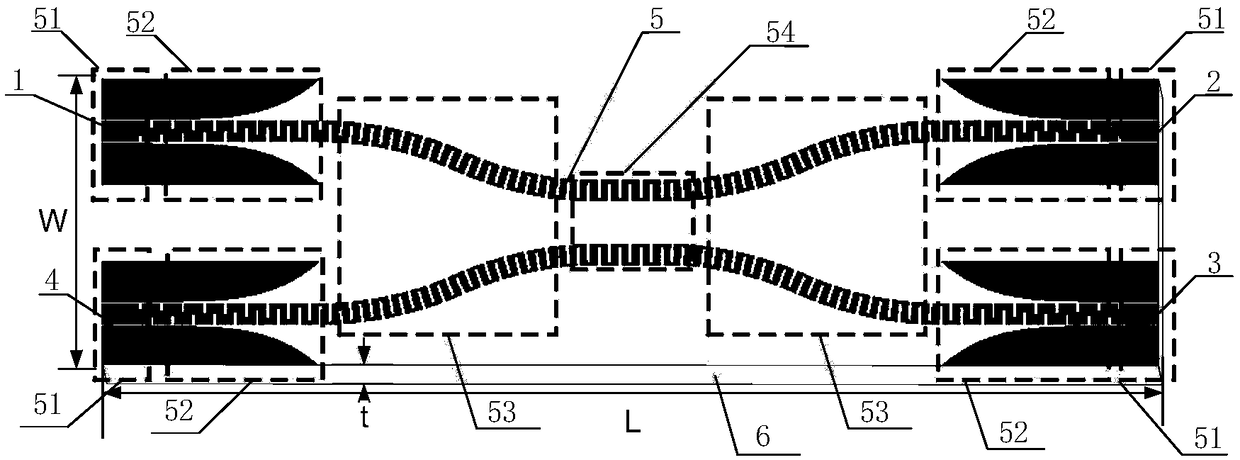

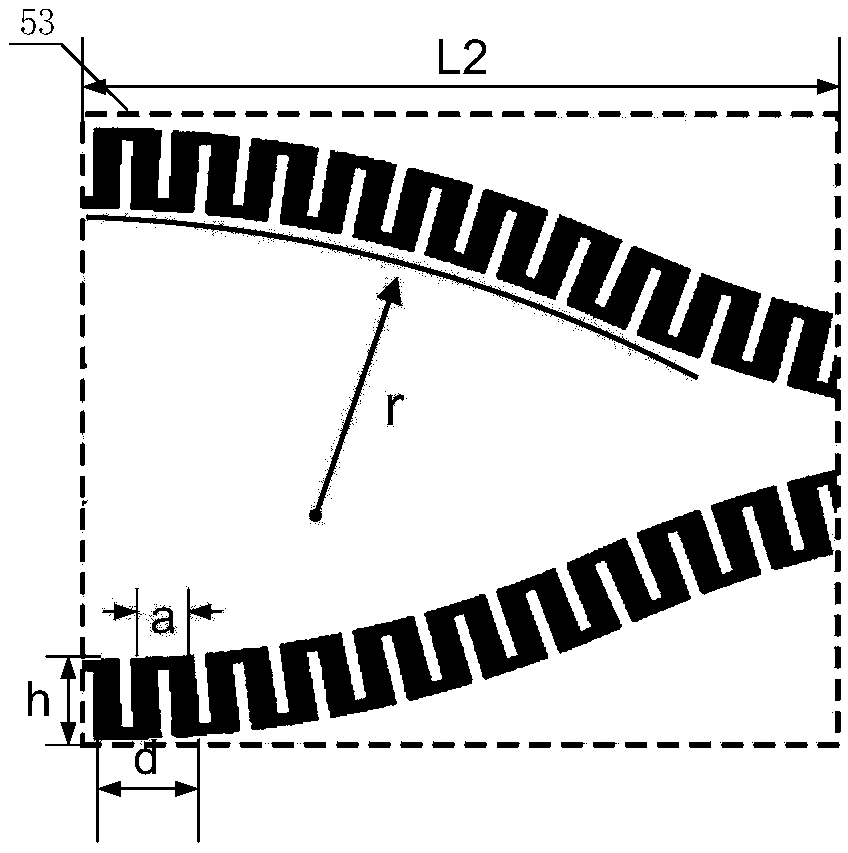

[0028] see figure 1 , the coupler of this example includes 4 ports, a conductor layer 5 and a dielectric board 6 . The conductor layer 5 passes the conductivity σ=6.301×10 7 The conductor layer 5 includes four feed structures 51 , four mode conversion structures 52 , two connection structures 53 and one coupling structure 54 . Each feed structure 51 is connected with each transition structure 52 to form a structural whole, which are respectively located at the upper left corner, lower left corner, lower right corner and upper right corner of the dielectric board. The coupling structure 54 is located in the center of the dielectric plate, and the two connecting structures 53 are respectively located on the left and right sides of the coupling structure 54, wherein the left end of the connecting structure 53 located on the left side of the coupling structure 54 and t...

Embodiment 2

[0034] Embodiment 2, working at 6-10GHz to realize the flexible microwave directional coupler with controllable coupling degree

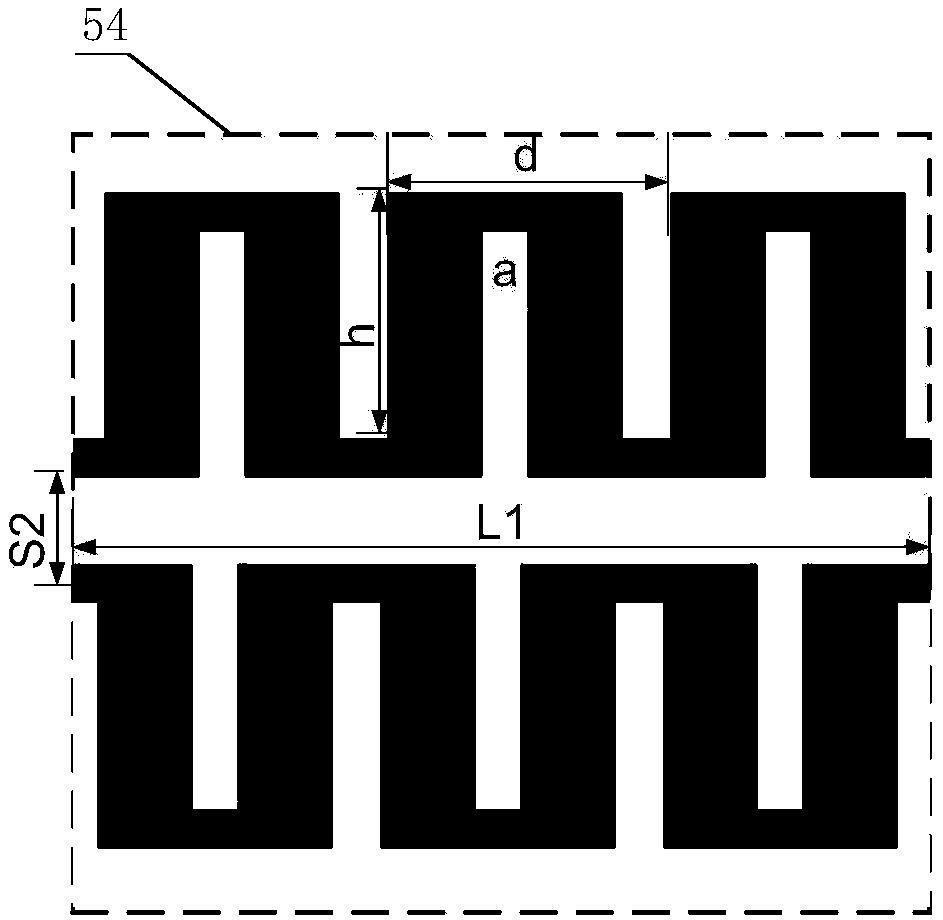

[0035] see figure 1 , figure 2 , Figure 4 , the structure of this embodiment 2 is the same as that of embodiment 1, only the coupling gap in the coupling structure 54 has been adjusted:

[0036] see image 3 , in the coupling structure 54, the coupling gap S2 between the parallel coupling lines is sequentially adjusted to 2mm, 4mm, 6mm, 8mm, 10mm, 12mm, 14mm, 16mm, so as to realize the adjustment of the coupling degree.

[0037] Effect of the present invention can be further illustrated by following simulation:

[0038] Simulation 1 simulates the transmission characteristics of the coupler in Embodiment 1 of the present invention, and the results are as follows Figure 5 . Figure 5 The abscissa is the frequency, the unit is GHz, the range is from 4GHz to 10GHz, and the ordinate is the decibel value of the S parameter amplitude, the unit is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com