A pose optimization method for structured light detection of off-axis aspheric surfaces

A technology of off-axis aspheric surface and optimization method, which is applied in the field of pose optimization of off-axis aspheric surface detection by structured light, can solve the problems of high detection cost and low sampling density, and achieves high sensitivity, loose position requirements, and large dynamic range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

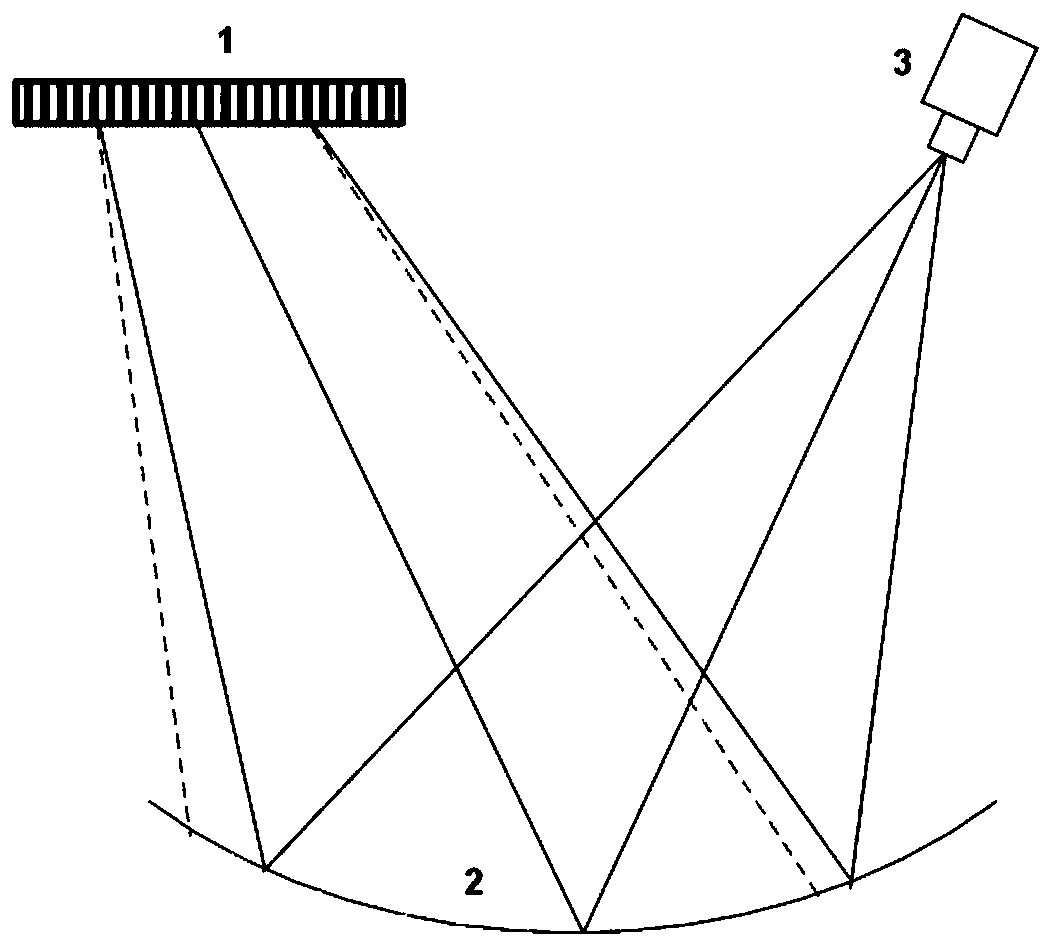

[0026] figure 1 It is a schematic diagram of the structure of the device used by the structured light detection off-axis aspheric pose optimization method of the present invention. The utilized device includes an LCD display screen 1 , a measured mirror surface 2 and a camera 3 . Combined with an example, the measurement process is as follows:

[0027] The first step is to make at least three marking points on the LCD display screen 1, the measured mirror surface 2 and the camera 3 respectively, and use a laser tracker to measure and obtain the spatial coordinate position information of each marking point;

[0028] In the second step, the horizontal and vertical sinusoidal stripes are respectively displayed on the LCD display 1, such as figure 2 and image 3 Shown, and use the camera 3 to shoot the fringes reflected by the measured specula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com