Method for recovering lead slag and utilizing waste heat in process of lead smelting

A technology of lead smelting and lead slag, which is applied in waste heat treatment, lighting and heating equipment, and improvement of process efficiency. Partial recovery and other issues, to overcome the disadvantages of waste heat resources, the equipment is simple and easy to operate, and the effect of efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

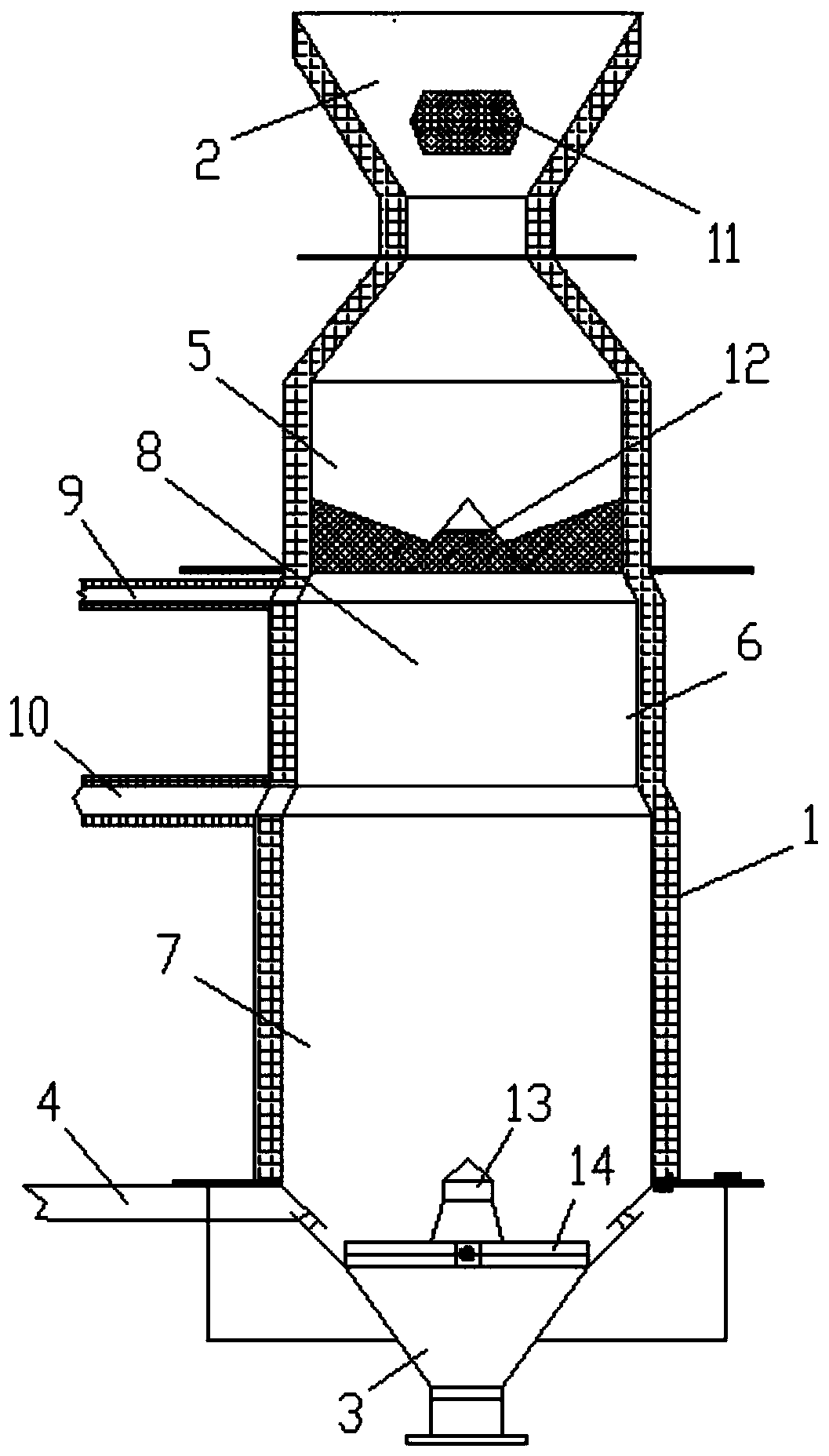

[0022] see figure 1 , a method for lead slag recovery and waste heat utilization in the lead smelting process, specifically as follows:

[0023] S1. Load the hot lead slag ore into a vertical closed tank from the feeding system. The temperature of the lead slag ore is 950°C to 1200°C;

[0024] S2. From the oxygen supply device at the bottom of the tank, low-temperature oxygen is uniformly fed to the entire cross-section of the tank. The ratio of the oxygen flow rate to the lead slag ore processing capacity, that is: the gas-solid ratio is 2000: 2500Nm 3 / t, make the hot lead slag fully contact with oxygen in the tank to cool down;

[0025] S3. The cooled lead slag ore is discharged from the bottom of the tank body, and the air carrying all the sensible heat of the lead slag ore after fully contacting with the lead slag ore is discharged from the upper part of the tank body and recovered by waste heat boiler to generate steam for heating, generate electricity.

[0026] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com