A pipeline joint for oil field gas recovery and its use method

A technology of pipeline joints and gas production pipes, which is applied in drilling pipes, casings, earthwork drilling and production, etc. It can solve the problems of waste of raw gas and easy leakage of joints, etc., and achieve the effect of prolonging service life and enhancing oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

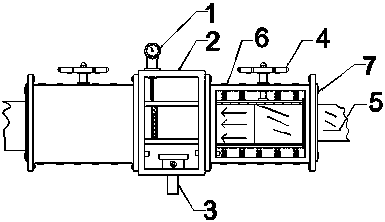

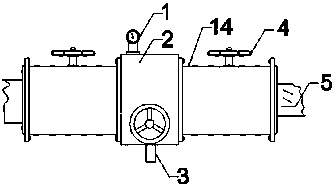

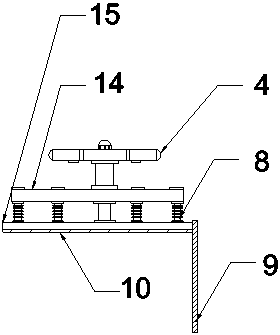

[0024] Such as Figure 1-4 As shown, the present invention is a pipeline joint for oilfield gas recovery, comprising: gas recovery pipe 5 and flange 7, one end of gas production pipe 5 is sleeved with flange 7, and one end of flange 7 is connected with a second set of threaded bolts. Pipe 14, the inner walls of both sides of the second casing 14 are interspersed with several telescopic rods 6, the outside of several telescopic rods 6 are sleeved with springs 8, and one end of several telescopic rods 6 is provided with a trachea fixing jacket 15 , one end of several springs 8 is respectively fixedly connected with the outer wall of the trachea fixing jacket 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com