Tile side bottom gap automatic filling device

An automatic filling and tile technology, which is applied in the direction of architecture and building construction, etc., can solve problems such as waste of resources, cracked tiles, large gaps at the side and bottom of tiles, etc., and achieve the effect of speeding up filling and saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

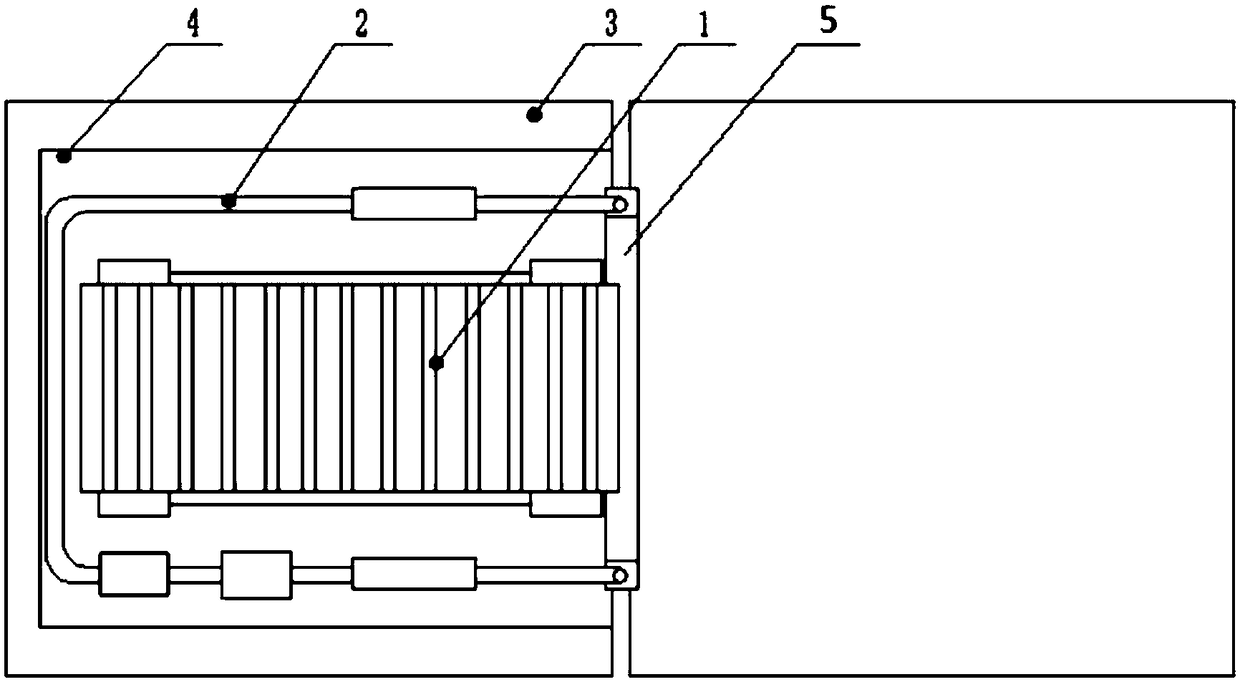

[0023] Embodiment 1: An automatic filling device for the gap at the bottom of the tile side, including: a transmission device 1, a sealing device 5, an iron powder conveying device 2 and a U-shaped base 4,

[0024] The upper surface of the ceramic tile 3 is provided with a U-shaped base 4, and the U-shaped base 4 is provided with a transmission device 1. The transmission device 1 is located directly above the gap at the bottom of the ceramic tile 3, and a sealing device 5 is provided in the gap of the ceramic tile 3. On the U-shaped base 4, An iron powder conveying device 2 is provided, and the iron powder conveying device 2 is connected with the sealing device 5 through a pipeline.

Embodiment 2

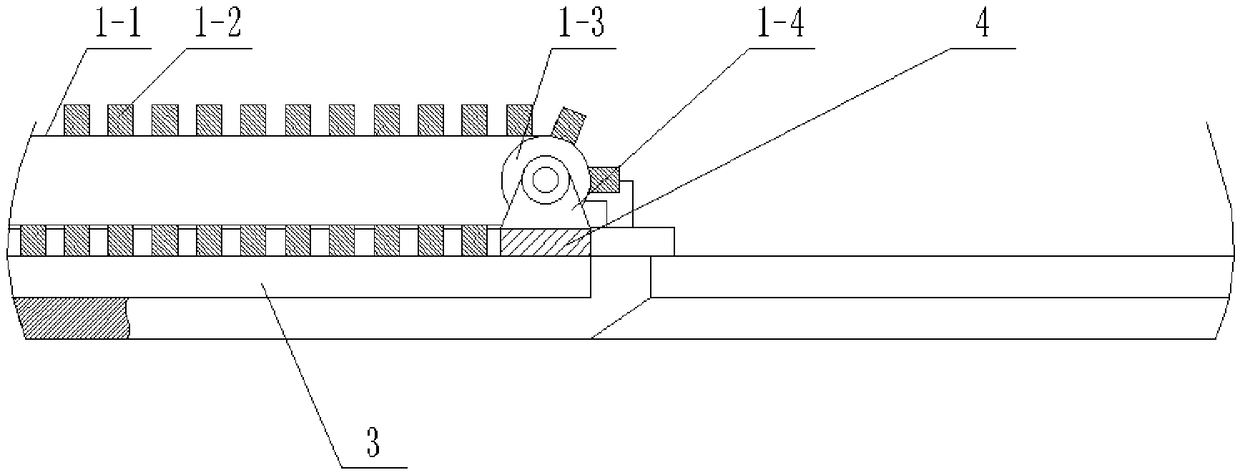

[0025] Embodiment 2: The transmission device 1 includes: a transmission belt 1-1, an electromagnet 1-2, a transmission roller 1-3 and a bearing seat 1-4, and the four corners of the U-shaped base 4 are provided with bearing seats 1-4 , the two ends of the transmission roller 1-3 are connected with the bearing seat 1-4, one end of the transmission roller 1-3 is connected with the output end of the drive motor, the transmission roller 1-3 is covered with a transmission belt 1-1, and the transmission belt 1-1 is provided with multiple The electromagnet 1-2, the driving motor and the electromagnet 1-2 are all connected to the controller arranged on the U-shaped base 4 through lines, so that the electromagnet 1-2 under the transmission belt 1-1 is energized sequentially from left to right , can absorb the iron powder delivered to achieve the purpose of filling, and at the same time, the rotation of the transmission belt 1-1 drives the iron powder to move to the interior of the botto...

Embodiment 3

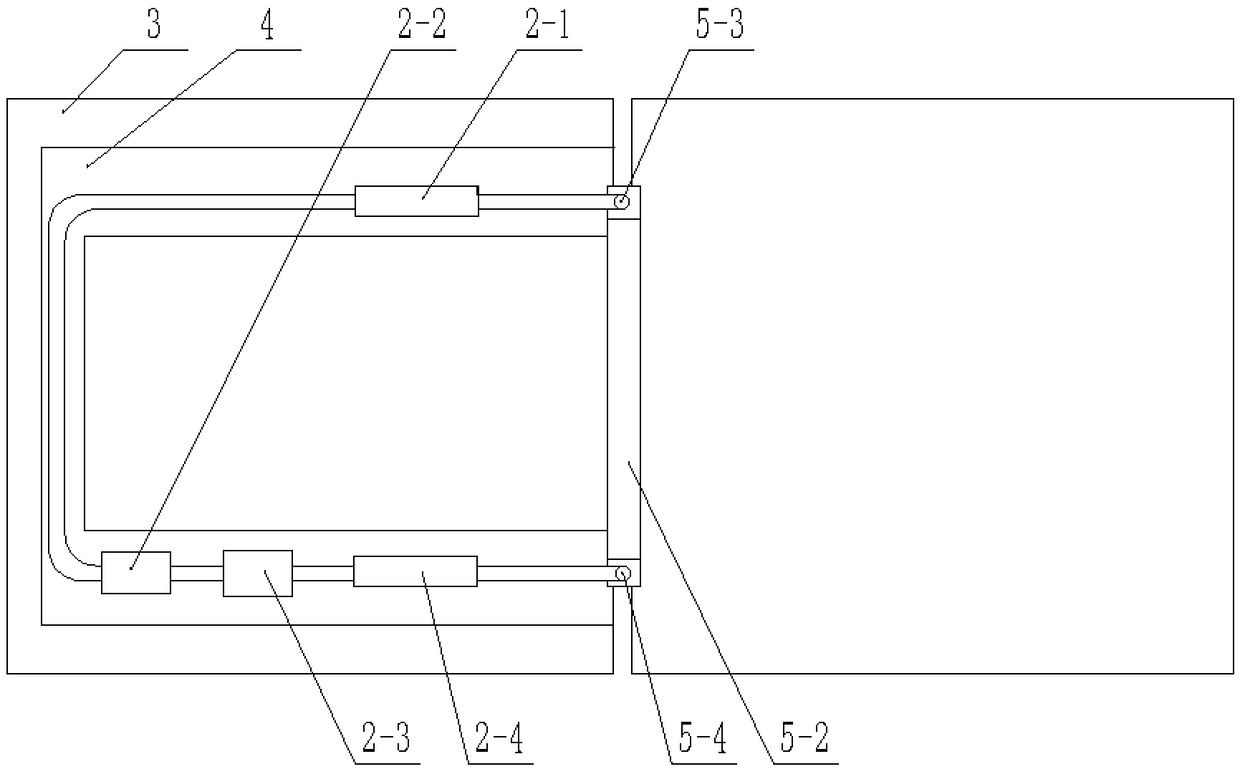

[0026] Embodiment 3: The sealing device 5 includes: a sealing block 5-1, a sealing cover plate 5-2, an iron powder outlet 5-3 and an iron powder inlet 5-4, and two sealing blocks are arranged in the gap between the tiles 3 5-1, the sealing block 5-1 is located at the two ends of the gap at the bottom of the ceramic tile 3, the sealing cover 5-2 is arranged above the sealing block 5-1, and the two ends of the upper end surface of the sealing cover 5-2 are respectively provided with iron The powder outlet 5-3 and the iron powder inlet 5-4, the iron powder outlet 5-3 and the iron powder inlet 5-4 are all connected to each other with the iron powder conveying device 2 through pipelines, so that it is arranged to ensure that the iron powder and air are not mixed. Leakage occurs, saving iron powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com