Directional explosion venting plate

An explosion-venting board and explosion-venting technology, which is applied in building components, thermal insulation, shockproof and other directions, can solve the problems of high cost and complex structure of the explosion-venting board, and achieve the effects of low cost, simple structure and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

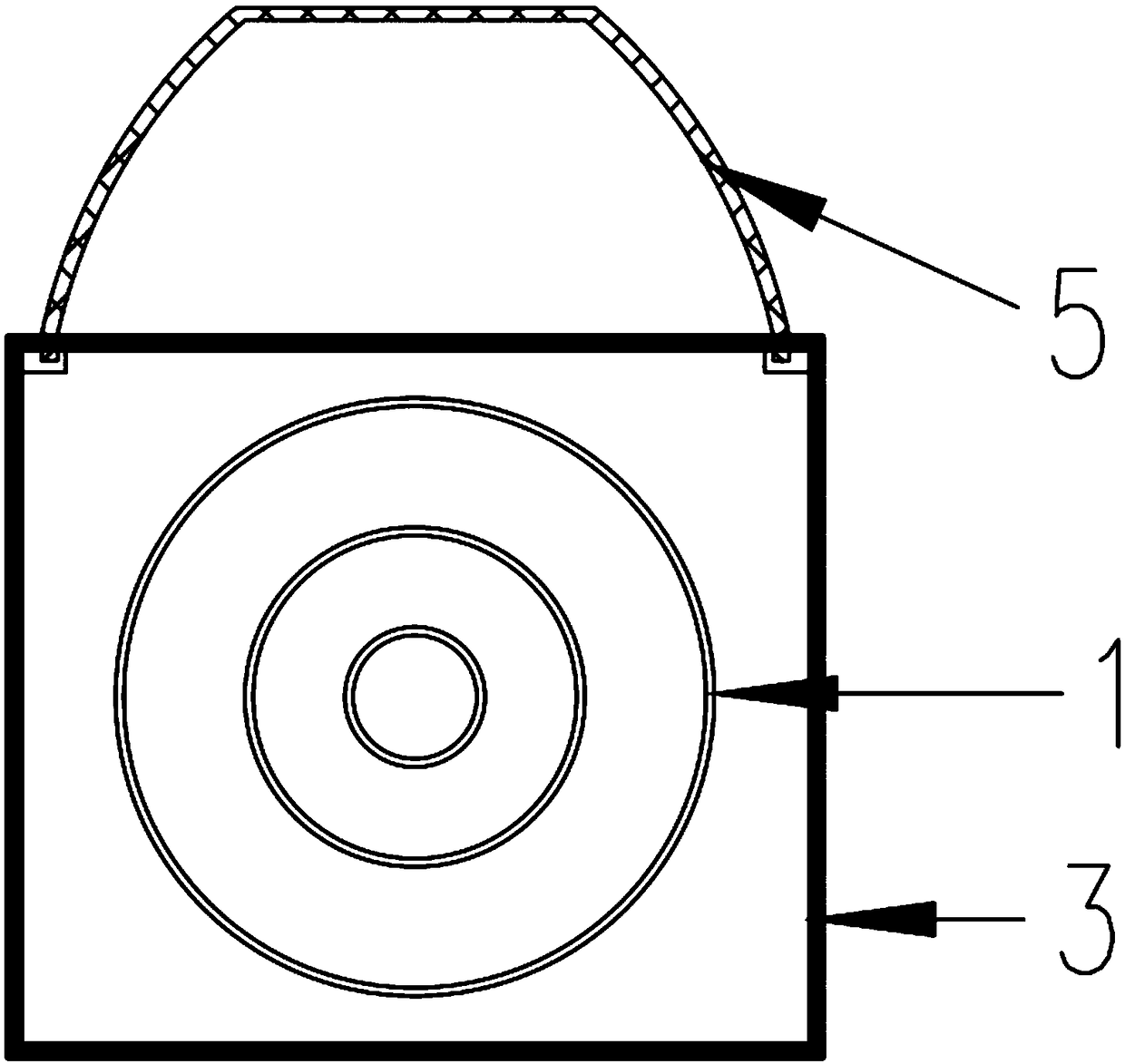

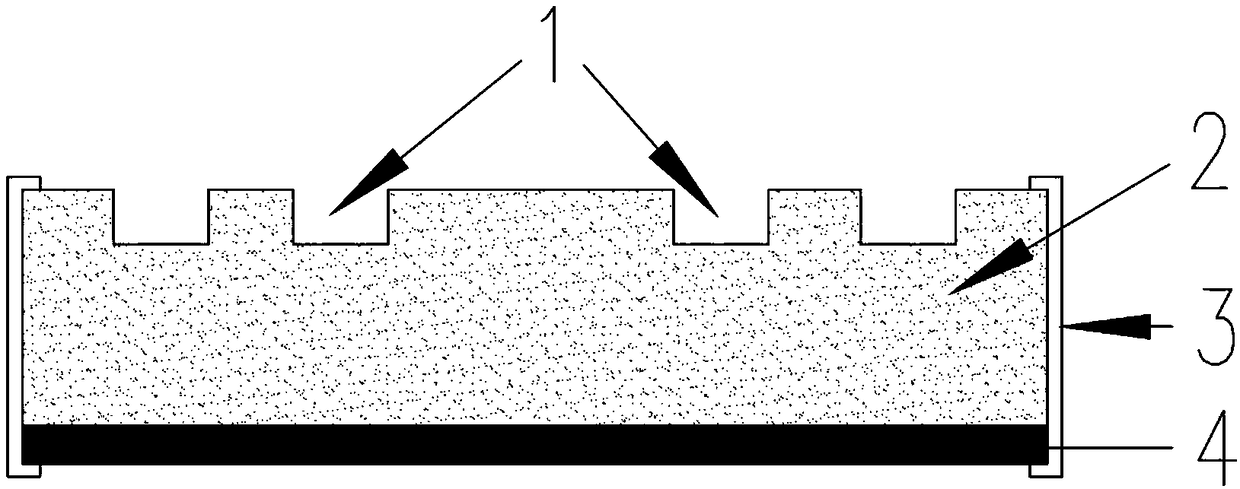

[0032] Such as figure 1 , figure 2 as well as image 3 As shown, a directional explosion venting panel is characterized in that it includes a main body layer 2, an anti-crack layer 4, a filling layer, an external surrounding frame 3 and a traction noose 5; the main body layer is made of silicate material, and the main body There is an explosion venting groove 1 on the front of the layer; the anti-crack layer 4 is an anti-crack material; the filling layer is an adhesive, and the filling layer is arranged between the main body layer 2 and the anti-cracking layer 4; The frame 3 is arranged on the peripheral periphery of the main body layer 2 .

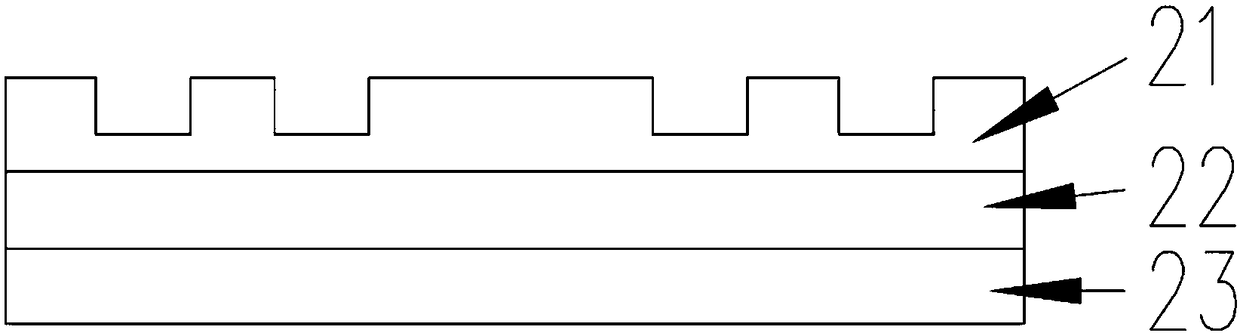

[0033] Preferably, the main body layer 2 includes an upper layer 21, a middle layer 22 and a lower layer 23, the middle layer 22 is a thermal insulation core layer, and the thermal insulation core layer is a foamed cement core layer, a cement perlite core layer and a cement core layer. One or more combinations in the core layer of pol...

Embodiment 2

[0046] Such as Figure 4 to Figure 8, the innovation of this application is to set up the explosion venting groove 1 on the main body of the explosion venting plate. When the explosion occurs, the whole plate will be impacted by the shock wave, because the explosion venting groove 1 is thinner than the surrounding area, and stress concentration will be formed. When the explosion vent plate is destroyed, it will start from the explosion vent groove 1, so as to realize the directional explosion venting. And the explosion vent groove 1 of the present application can be arranged freely, Figure 4 It is the layout method of explosion vent 1 commonly used in this application. It is a concentric circle mode. The center of the explosion vent plate is used as a concentric circle. The radius of the concentric circle is set according to the explosion venting requirements. The radius difference can be 10-50cm. When an explosion occurs , the middle of the explosion vent plate is the stres...

Embodiment 3

[0048] In the explosion venting plate described in this embodiment, the main body layer 2 is a silicate solid layer, and an explosion venting groove 1 is opened on the silicate solid layer; the main body layer 2 is divided into three layers: the upper layer 21 , the middle layer 22 and the lower layer 23; the middle layer 22 is a lightweight thermal insulation material layer, and the lightweight thermal insulation material layer is an inorganic vitrified microbead material, and the inorganic vitrified microbead material is filled on the main body layer holes; the external surrounding frame 3 is arranged on the periphery of the main body layer 2, and is an integrally formed inverted "L"-shaped structure.

[0049] The preparation method of the explosion-venting plate described in the present embodiment is as follows:

[0050] Step 1: first use an electric welding machine to weld the outer frame 3 into shape, and then form an integrated inverted "L" structure;

[0051] Step 2: S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com