Self-repairing anticorrosive outdoor building graphene coating and preparation method thereof

A graphene and self-repairing technology, which is applied in the direction of anti-corrosion coatings, microsphere preparation, microcapsule preparation, etc., can solve problems such as difficult to meet the needs of use, limited self-repair ability, poor anti-corrosion performance, etc., and achieve high self-repair efficiency, Improve anti-corrosion performance, improve the effect of anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

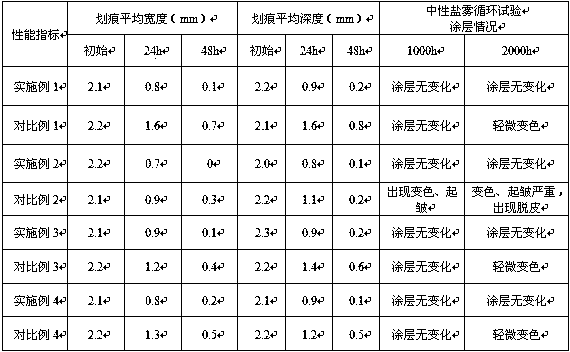

Examples

Embodiment 1

[0030] (1) Add isophorone diisocyanate into the reactor, heat to 53°C, add the catalyst dropwise under magnetic stirring, then slowly drop into the mixed aqueous solution of 1,4-butanediol and cyclohexanone, and raise the temperature to 63°C ℃ for 5.5 hours, cooled to 6 ℃ for 1.5 hours to obtain the BD-IPDI capsule core precursor material; in the capsule core precursor material reaction system, water, 1,4-butanediol, cyclohexanone, isophorone diisocyanate , The mass ratio of catalyst is 100:35:30:35:3; Catalyst is dibutyltin dilaurate;

[0031] (2) Add toluene diisocyanate into the reactor, heat to 41°C, add the catalyst dropwise under magnetic stirring, then slowly drop into the mixed solution of 1,4-butanediol and cyclohexanone, raise the temperature to 51°C and stir the reaction 4.5h, cool down to 6°C and refrigerate for 1.5h to obtain BD-TDI capsule wall precursor material; in the capsule wall precursor material reaction system, the mass ratio of water, 1,4-butanediol, cyc...

Embodiment 2

[0040] (1) Add isophorone diisocyanate into the reactor, heat to 50°C, add the catalyst dropwise under magnetic stirring, then slowly drop into the mixed aqueous solution of 1,4-butanediol and cyclohexanone, and raise the temperature to 60°C React at ℃ for 6 hours, cool down to 3℃ and refrigerate for 1 hour to obtain the BD-IPDI capsule core precursor material; in the capsule core precursor material reaction system, water, 1,4-butanediol, cyclohexanone, isophorone diisocyanate, catalyst The mass ratio is 100:30:25:30:2; the catalyst is dibutyltin dilaurate;

[0041] (2) Add toluene diisocyanate into the reactor, heat to 40°C, add the catalyst dropwise under magnetic stirring, then slowly drop into the mixed solution of 1,4-butanediol and cyclohexanone, raise the temperature to 50°C and stir the reaction After 4.5 hours, cool down to 3°C and refrigerate for 1 hour to obtain the BD-TDI capsule wall precursor material; in the capsule wall precursor material reaction system, the m...

Embodiment 3

[0048] (1) Add isophorone diisocyanate into the reactor, heat to 55°C, add the catalyst dropwise under magnetic stirring, then slowly drop into the mixed aqueous solution of 1,4-butanediol and cyclohexanone, and raise the temperature to 65°C React at ℃ for 5 hours, cool down to 8℃ and refrigerate for 2 hours to obtain the BD-IPDI capsule core precursor material; in the capsule core precursor material reaction system, water, 1,4-butanediol, cyclohexanone, isophorone diisocyanate, catalyst The mass ratio is 100: 40: 35: 40: 4; The catalyst is dibutyltin dilaurate;

[0049] (2) Add toluene diisocyanate into the reactor, heat to 45°C, add the catalyst dropwise under magnetic stirring, then slowly drop into the mixed solution of 1,4-butanediol and cyclohexanone, raise the temperature to 55°C and stir the reaction 5h, cool down to 8°C and refrigerate for 2h to obtain the BD-TDI capsule wall precursor material; in the capsule wall precursor material reaction system, the mass ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com