High-purity, small-particle-diameter and low-solvent-residue azilsartan bulk drug and preparation method thereof

A technology for raw materials and solvents, applied in the field of drug synthesis, can solve the problems of large particle size, high solvent residue, low purity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

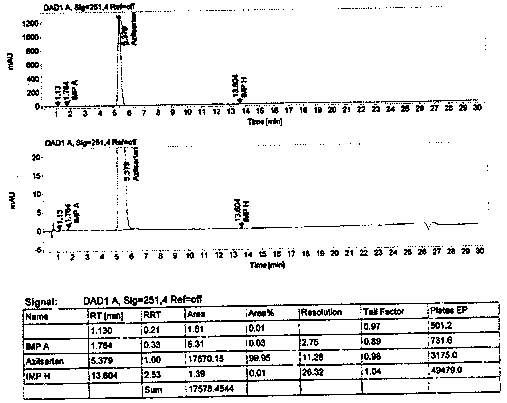

Image

Examples

Embodiment 1

[0105] The preparation of embodiment 1 compound III-1

[0106]

[0107] Add 60g of N,N-dimethylformamide into the reaction flask, add 19.5g of sodium carbonate under stirring, stir evenly, add 8.5g of hydroxylamine hydrochloride, raise the temperature to 35°C, stir for 30 minutes, add 25g of compound IV-1, Continue to raise the temperature to 60°C, and stir for 24 hours. After the reaction, cool down to crystallize, and filter to obtain the crude compound III-1. The obtained crude product and DMSO were added into a reaction flask, heated up for crystallization for 1 hour, cooled down for crystallization, filtered, and dried to obtain compound III-1 with a yield of 75%.

Embodiment 2

[0108] The preparation of embodiment 2 compound II-1

[0109]

[0110] Add 30g of ethyl acetate, 15g of compound III-1, and 3g of trimethylamine into the reaction flask, stir, cool down to 5°C, slowly add 5.1g of isopropyl chloroformate, and continue the reaction at this temperature. Water was added to quench, the aqueous layer was washed once with ethyl acetate, the ethyl acetate solution was combined, the ethyl acetate layer was washed once with water, and concentrated under reduced pressure to obtain solid V-1. Add the obtained solid V-1 and toluene into a reaction flask, stir and raise the temperature to 100°C for reaction. After the reaction, cool down to crystallize, and filter to obtain the crude compound II-1. The obtained crude product II-1 was added to toluene, stirred and crystallized at 50° C. for 1 h, cooled to 10° C., stirred and crystallized for 1 h, and filtered and dried to obtain compound II-1 with a yield of 77%.

Embodiment 3

[0111] Example 3 Preparation of Compound III-2

[0112]

[0113] Add 200g DMSO to the reaction bottle, add 18g sodium hydroxide under stirring, stir evenly, add 24g hydroxylamine hydrochloride, heat up to 70°C, stir for 2h, add 25g of compound IV-2, continue to heat up to 85°C, stir for 20h, After the reaction, the temperature was lowered for crystallization and filtered to obtain the crude compound III-2. The obtained crude product, DMF and acetone mixed solution were added into a reaction flask, heated up for crystallization for 3 hours, cooled down for crystallization, filtered, and dried to obtain compound III-2 with a yield of 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com