Lightning Protection Eco-environmental Protection Foundation and System Prepared by Graphene

A graphene and environmental protection technology, which is applied in the field of lightning protection ecological environmental protection foundation and system, can solve the problems of complex construction, high cost, and easy corrosion, and achieve the effect of simple process flow, reduced construction steps, and strong electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

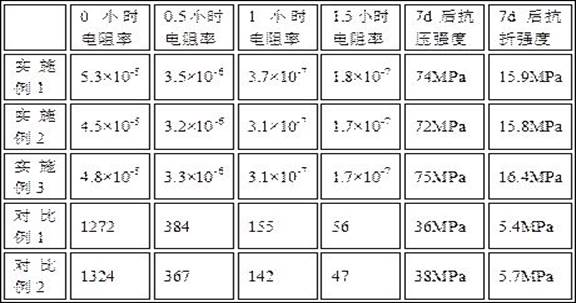

Examples

Embodiment 1

[0032] A new lightning protection material for multi-field applications prepared from graphene. The components by weight are: 125 parts of cement, 95 parts of sand, 100 parts of crushed stone, and 12 parts of additives;

[0033] The additives are: 4 parts of graphene, 25 parts of carbon fiber, 6 parts of potassium aluminum sulfate dodecahydrate, 7 parts of ferric chloride, 15 parts of aluminum sulfate, and 5 parts of zirconocene dichloride.

[0034] The preparation method is:

[0035] 1: Preparation of lightning protection additives: select each component according to the formula ratio, first mix ferric chloride and aluminum sulfate evenly, then add graphene, carbon fiber, zirconocene dichloride and stir for 6 minutes with ultrasonic waves, control the temperature 20- 55°C, then add the rest of the components and mix them evenly by mechanical stirring.

[0036]2: Preparation of new lightning protection materials: select each component according to the formula ratio, and mix t...

Embodiment 2

[0038] A new lightning protection material for multi-field applications made of graphene, the components by weight are: 180 parts of cement, 150 parts of sand, 60 parts of gravel, and 27 parts of additives;

[0039] The additives are: 13 parts of graphene, 15 parts of carbon fiber, 18 parts of potassium aluminum sulfate dodecahydrate, 16 parts of ferric chloride, 8 parts of aluminum sulfate, and 13 parts of zirconocene dichloride.

[0040] The preparation method is:

[0041] 1: Preparation of lightning protection additives: select each component according to the formula ratio, first mix ferric chloride and aluminum sulfate evenly, then add graphene, carbon fiber, zirconocene dichloride and stir for 15 minutes with ultrasonic waves, control the temperature at 25- 40°C, then add the rest of the components and mix them evenly by mechanical stirring.

[0042] 2: Preparation of new lightning protection materials: select each component according to the formula ratio, and mix the li...

Embodiment 3

[0044] A new lightning protection material for multi-field applications prepared from graphene. The components by weight are: 150 parts of cement, 125 parts of sand, 85 parts of crushed stone, and 16 parts of additives;

[0045] The additives are: 9 parts of graphene, 23 parts of carbon fiber, 12 parts of potassium aluminum sulfate dodecahydrate, 11 parts of ferric chloride, 13 parts of aluminum sulfate, and 9 parts of zirconocene dichloride.

[0046] The preparation method is:

[0047] 1: Preparation of lightning protection additives: select each component according to the formula ratio, first mix ferric chloride and aluminum sulfate evenly, then add graphene, carbon fiber, zirconocene dichloride and stir for 12 minutes with ultrasonic waves, control the temperature 20- 55°C, then add the rest of the components and mix them evenly by mechanical stirring.

[0048] 2: Preparation of new lightning protection materials: select each component according to the formula ratio, and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com