Fast cooling bottle cap

A rapid cooling and bottle cap technology, applied in the field of bottle caps, can solve the problems of not being able to drink immediately, scalding water, etc., and achieve the effect of convenient processing, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is further described

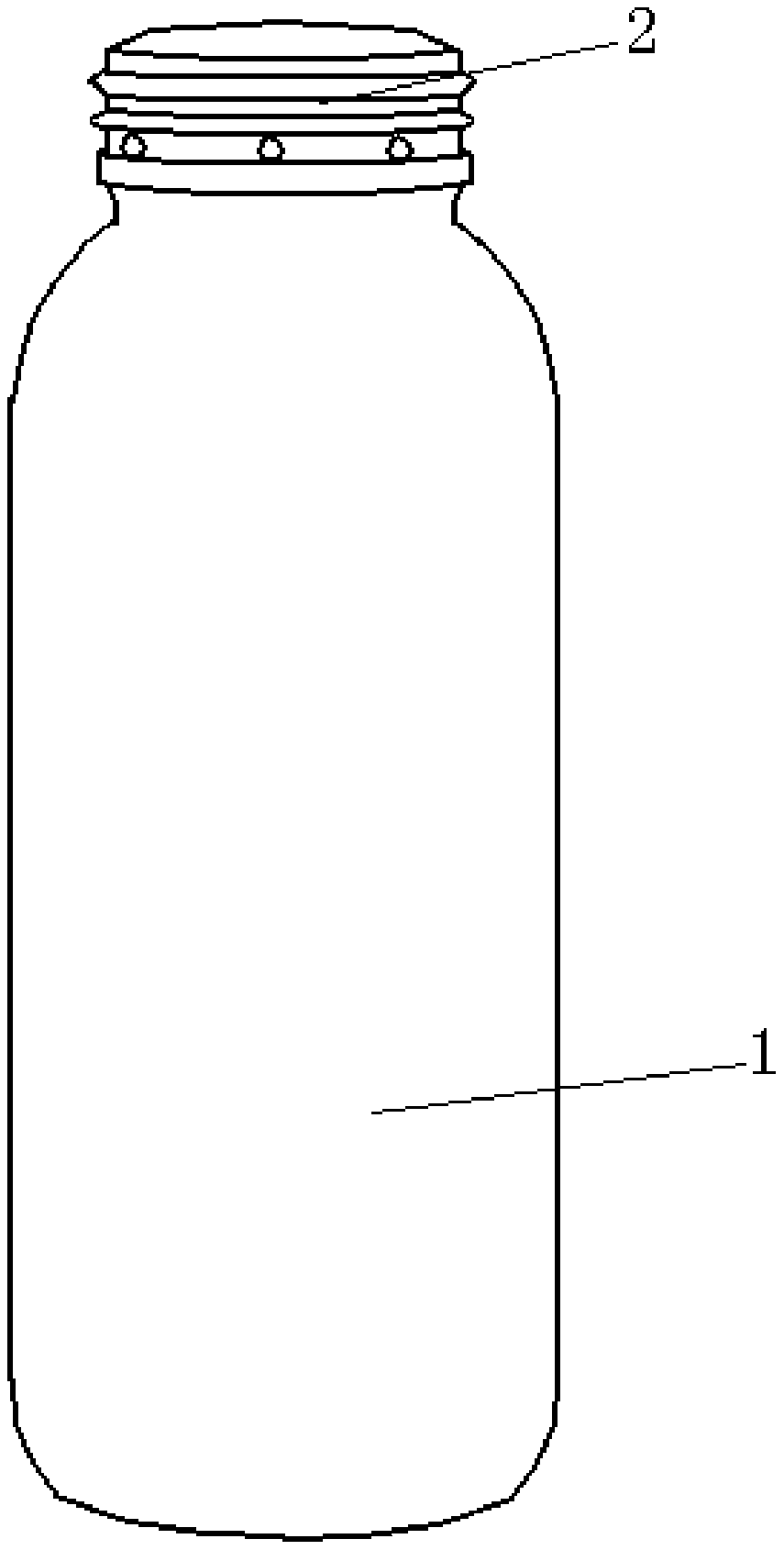

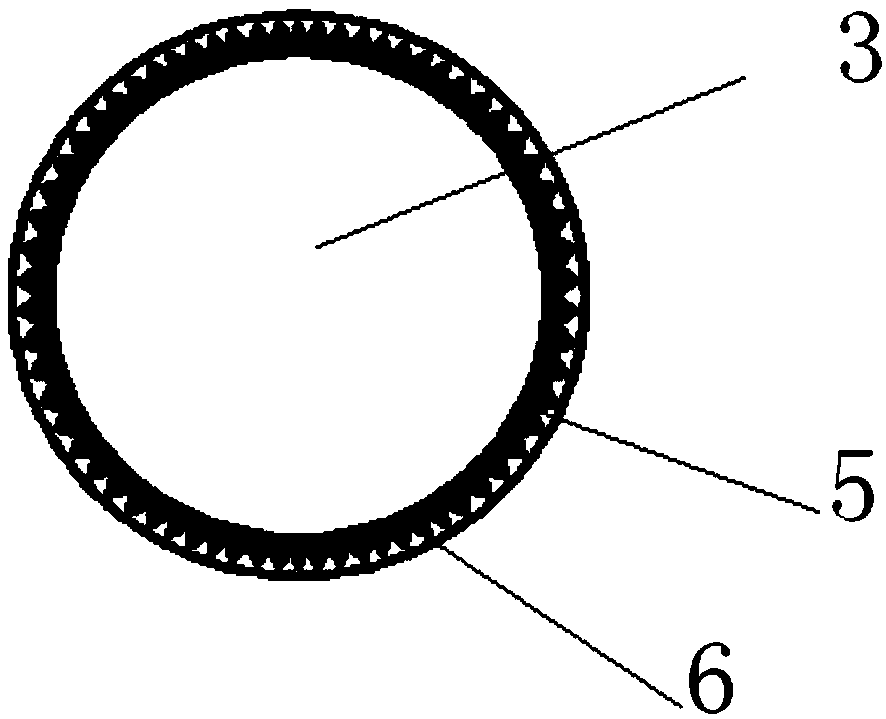

[0021] Such as Figure 1 to Figure 2 A kind of fast cooling bottle cap shown comprises a bottle body 1 and a bottle cap 3, the bottle cap 3 is connected with the bottle mouth 2 on the bottle body 1, and a heat insulating sleeve 6 is arranged outside the bottle cap 3. The bottle cap 3 is provided with a cooling hole column 5 .

[0022] Further, the radiating hole column 5 is provided with a cooling strip, the number of the cooling strip is 2 or more, and the material of the cooling hole column 5 is non-toxic plastic and / or rubber and / or Or metal and / or ceramics and / or any good conductor of heat with a heat transfer coefficient greater than 2W / (m K) and / or a poor conductor of heat with a heat transfer coefficient of less than 0.2W / (m K) and / or heat transfer materials The thermal coefficient is between 0.2-2 W / (m·K) ordinary thermal conductors.

[0023] Further, the bottle cap 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com