Intelligent welding system and working method thereof

A welding system and intelligent technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as high dependence, waste of labor costs, production accidents, etc., to reduce human dependence and improve automation degree and production efficiency, effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

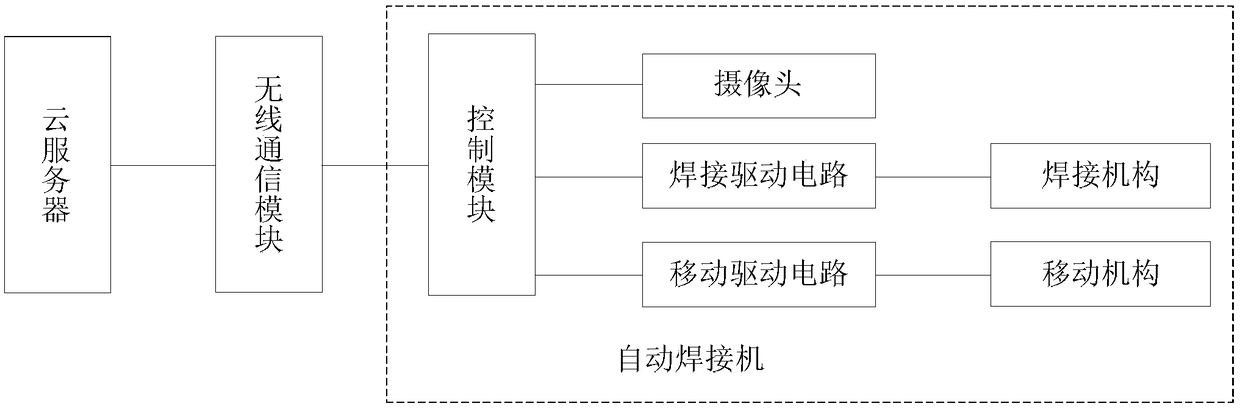

[0025] figure 1 It is a functional block diagram of the intelligent welding system of the present invention.

[0026] Such as figure 1 As shown, this embodiment 1 provides an intelligent welding system, including: a cloud server, an automatic welding machine controlled and driven by a control module, and a wireless communication module for information transmission between the two; the control module is suitable for The welding information of the workpiece is obtained from the cloud server through the wireless communication module to control the automatic welding machine for welding.

[0027] The intelligent welding system of this embodiment 1 obtains the welding information of the workpiece from the cloud server through the control module, and controls the automatic welding machine to perform welding, which reduces the dependence of the welding process on people, and also reduces the influence of human factors on the welding quality. Increased automation and production effic...

Embodiment 2

[0051] On the basis of Embodiment 1, this Embodiment 2 provides a working method of an intelligent welding system, including: a cloud server and an automatic welding machine; Obtain the welding information of the workpiece to control the automatic welding machine for welding.

[0052] For the specific structure and implementation process of the intelligent welding system, please refer to the related discussion of Embodiment 1, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com