Lithium battery core sorting device and sorting method

A technology for sorting devices and lithium batteries, applied in sorting and other directions, can solve problems such as mismatching of technical parameters, attenuation of cycle life, uneven real-time voltage distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

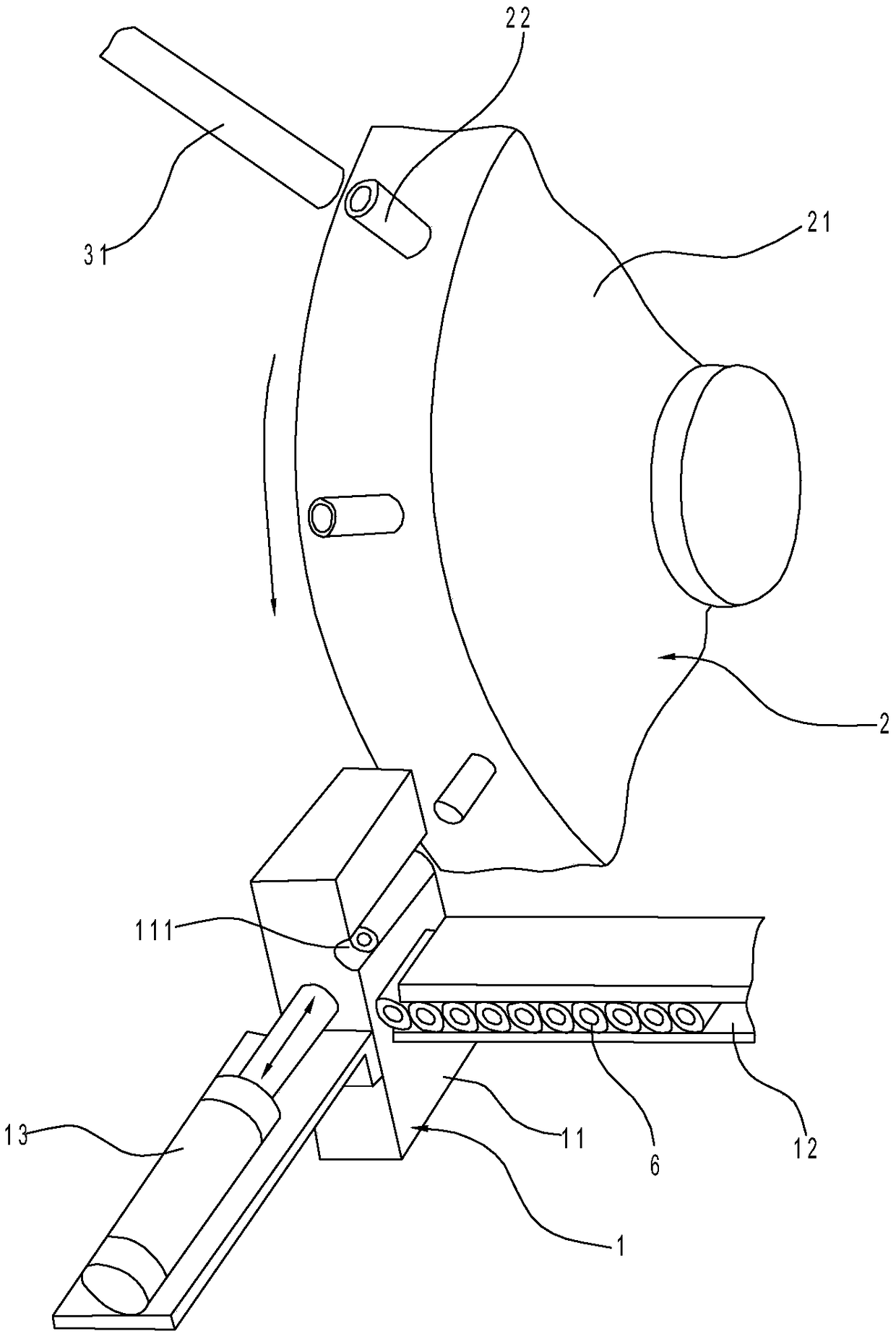

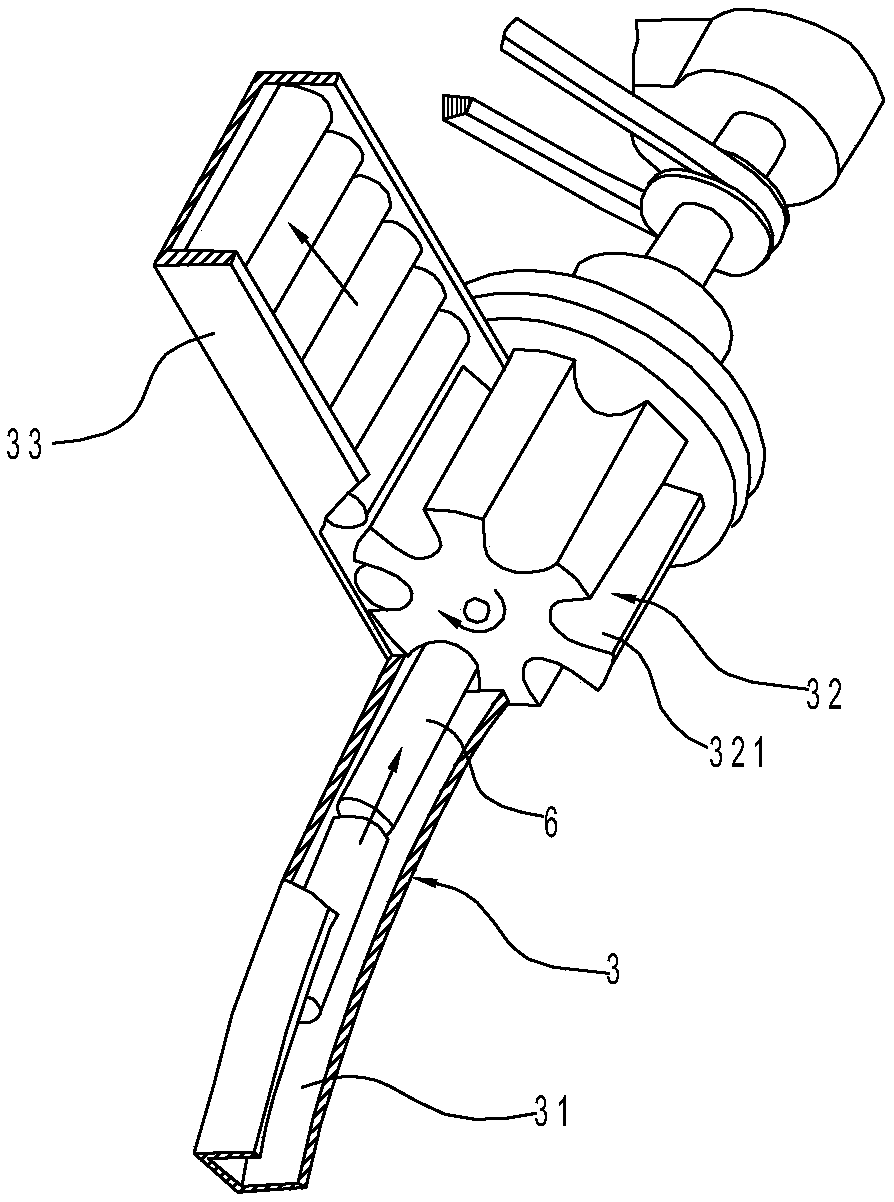

[0026] Such as Figures 1 to 5 As shown, the lithium battery cell sorting device in this implementation includes a feeding mechanism 1 , a detection mechanism 2 , an aggregation conversion mechanism and a sorting mechanism 5 .

[0027] Wherein, the feeding mechanism 1 comprises a feeding fixed block 11, a feeding channel 12 and a feeding cylinder 13, and the feeding fixing block 11 is provided with a cell groove 111 for horizontally accommodating lithium batteries 6, and the feeding channel 12 is vertically It is arranged directly above the cell slot 111 , the feeding cylinder 13 is located on one side of the feeding fixing block 11 , and the piston rod of the feeding cylinder 13 is opposite to the cell slot 111 .

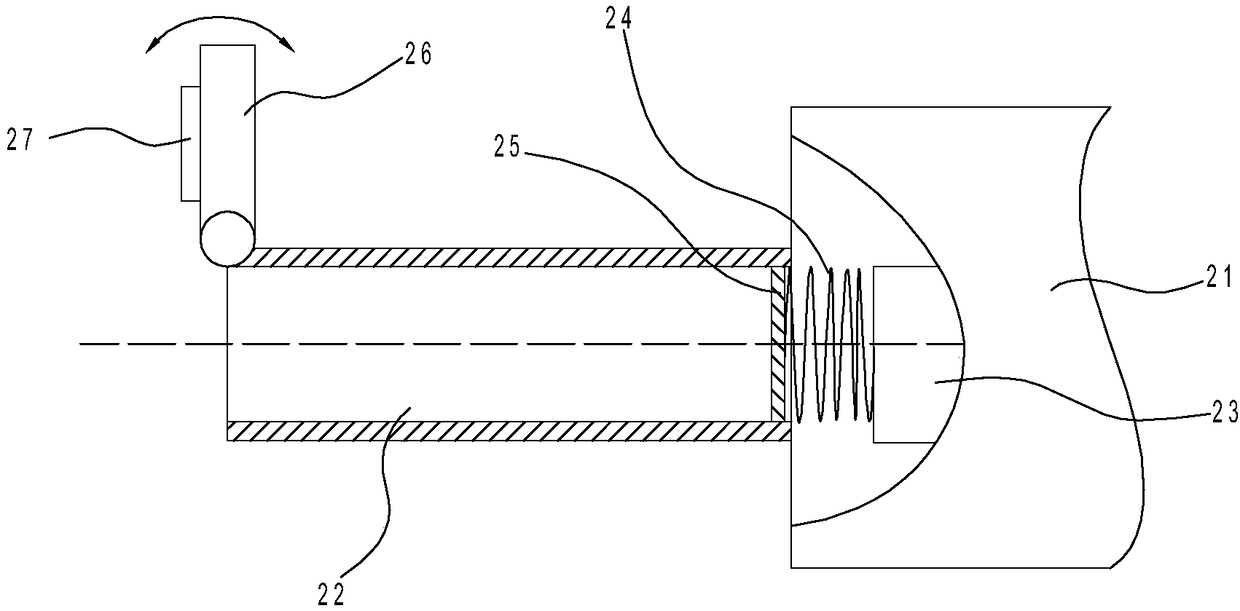

[0028] The detection mechanism 2 includes a detection turntable 21 located on the other side of the feeding fixed block 11 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com