Composite grid-type air purifying filter core

An air purification and grid-type technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve the problems of difficult cleaning of filter elements, and achieve the effect of improving air purification efficiency, prolonging residence time, and increasing circulation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

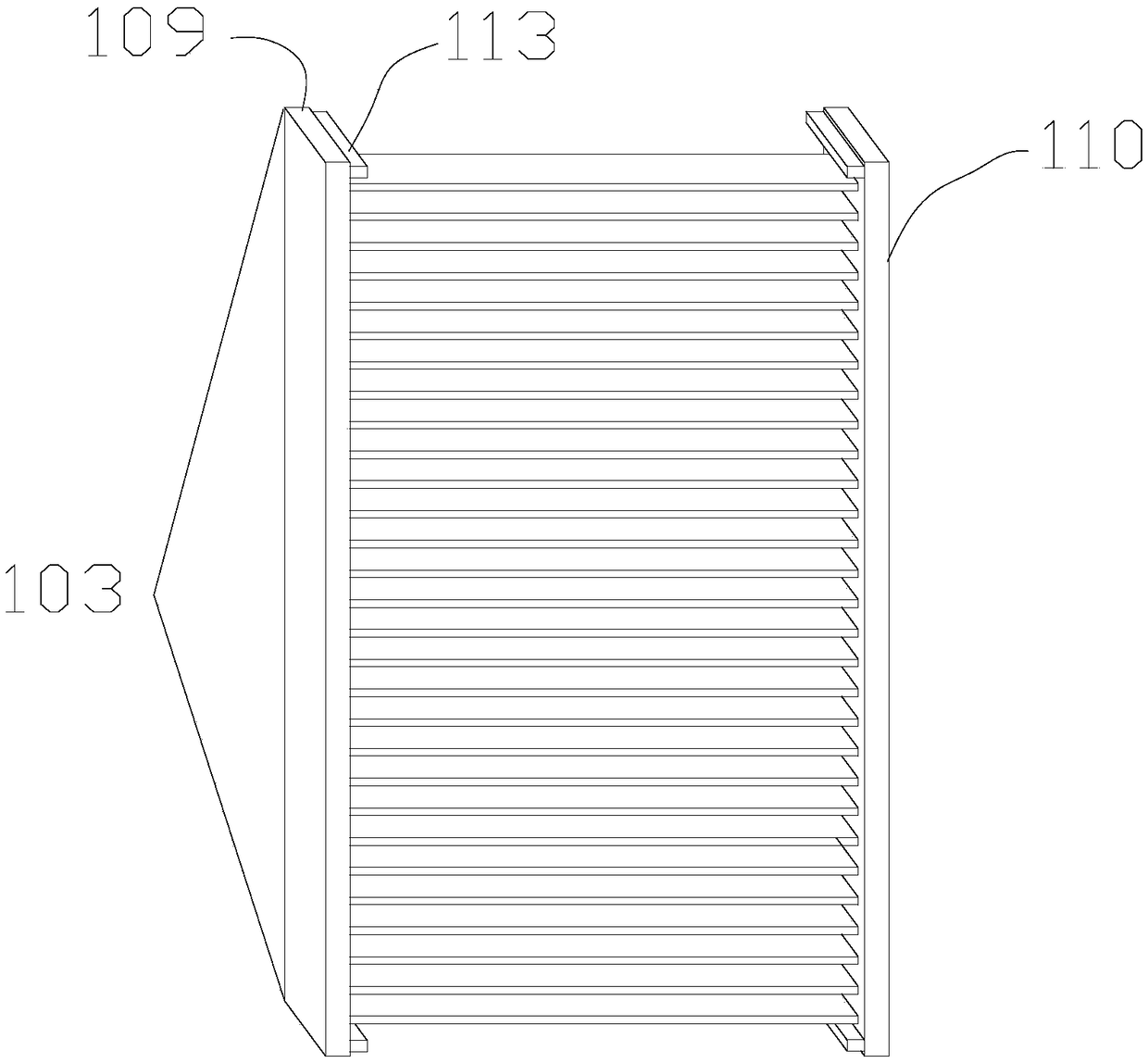

[0044] This embodiment provides a composite mesh-type air purification filter element, including a cuboid housing 101, the housing 101 is a frame structure, and the housing 101 is composed of an upper plate, a left plate, a lower plate and a right plate connected end to end in sequence; The first net plate 102, the second net plate 103 and the filter plate 104 are detachably arranged between the plate and the lower plate, and the first net plate 102 and the second net plate 103 are sandwiched between the two filter plates 104, and the two The two filter plates 104 are symmetrical to each other, and the plates are arranged in parallel; the first screen plate 102 is provided with a vertical grid, the second screen plate 103 is provided with a horizontal grid, and the vertical grid on the first screen plate 102 and the vertical grid are arranged on the second screen plate 103. The horizontal grids on the second screen 103 are arranged in a staggered manner to form a grid structure...

Embodiment 2

[0046] Further improvement on the basis of Embodiment 1, the first net plate 102 includes a fixed plate I106 and a fixed plate П107, the fixed plate I106 and the fixed plate П107 are all rectangular parallelepiped plate structures, and the fixed plate I106 is used for the upper plate of the housing 101 Parallel contact connection, the fixed plate П107 is used for parallel contact connection with the lower plate of the housing 101; several partitions 108 are arranged between the fixed plate 1106 and the fixed plate П107, and the partitions 108 are rectangular parallelepiped. The board surfaces between the boards 108 are parallel to each other, and are distributed in a straight line at equal intervals along the axial direction of the fixed board I106 or the fixed board П107. connect;

[0047] The second net plate 103 includes a fixed plate III109 and a fixed plate IV110, the fixed plate III109 is used for parallel contact connection with the left plate of the housing 101, and th...

Embodiment 3

[0049] Further improvement on the basis of embodiment 2, both end surfaces of the long axis direction of the fixed plate I106 and the two ends of the long axis direction of the fixed plate П107 are provided with chute 112, and the extension direction of the chute 112 is consistent with that of the fixed plate I106 or the fixed plate The axial direction of П107 is vertical; the inner surface of both ends of the long axis direction of the fixed plate III109 and the inner plate surface of both ends of the long axis direction of the fixed plate IV110 are protrudingly provided with slide rails 113 that are slidably adapted to the chute 112; And the groove on the outer wall of the slide rail 113 is provided with a plurality of limiting grooves 114 , and the inner wall of the sliding groove 112 is provided with a plurality of elastic limiting protrusions 115 for inserting into the limiting grooves 114 for fixing. Both the fixed plate I106 and the fixed plate П107 are provided with thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com