End face uniform pumping type solid laser device

A solid-state laser and pump light technology, applied in the field of lasers, can solve the problems of laser damage, laser crystal bursting, and laser crystal heat cannot be effectively dissipated, and achieve the effects of compressed pulse width, narrow pulse width, and reduced thermal lens effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

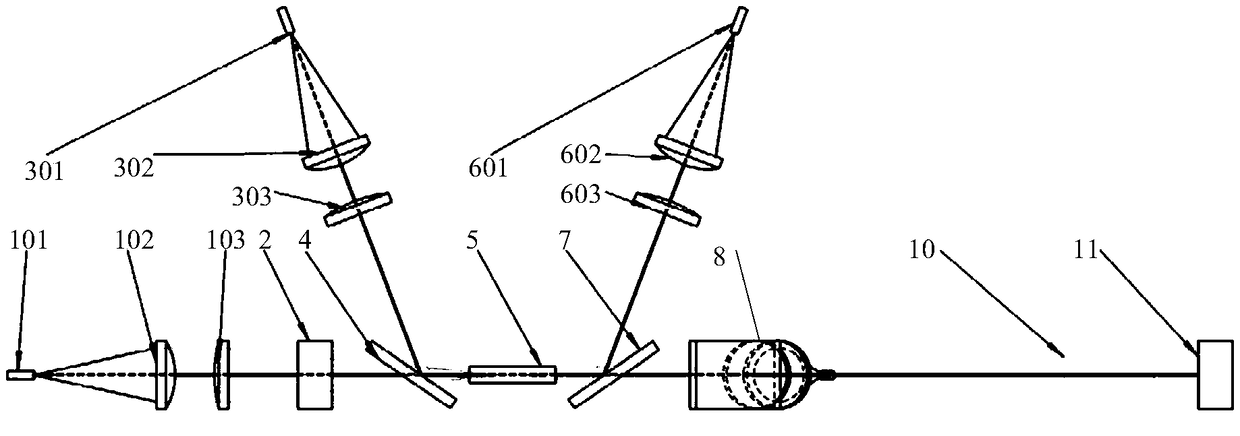

[0031] refer to Figures 1 to 4 As shown, the present invention provides a solid-state laser with uniform end face pumping, including a first laser pump source assembly 1, a thermally compensated negative lens 2, a second laser pump source assembly 3, a second pump source reflector 4, a laser Crystal 5, third laser pumping source component 6, third pumping source reflector 7, fourth laser pumping source component 8, fourth pumping source reflector 9, Q switch 10, laser output mirror 11; The thermal compensation negative lens 2 and the laser output mirror 11 form a laser resonant cavity. In the laser resonant cavity, the second pumping source reflector 4, the laser crystal 5, the second pumping source reflector 4, the laser crystal 5, and the Three pump source reflectors 7, a fourth pump source reflector 9, and a Q switch 10; the first laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com