Sealing structure for repairing pebble-bed high-temperature reactor device

A sealed structure, high-temperature reactor technology, applied in sealing, reactors, reducing greenhouse gases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

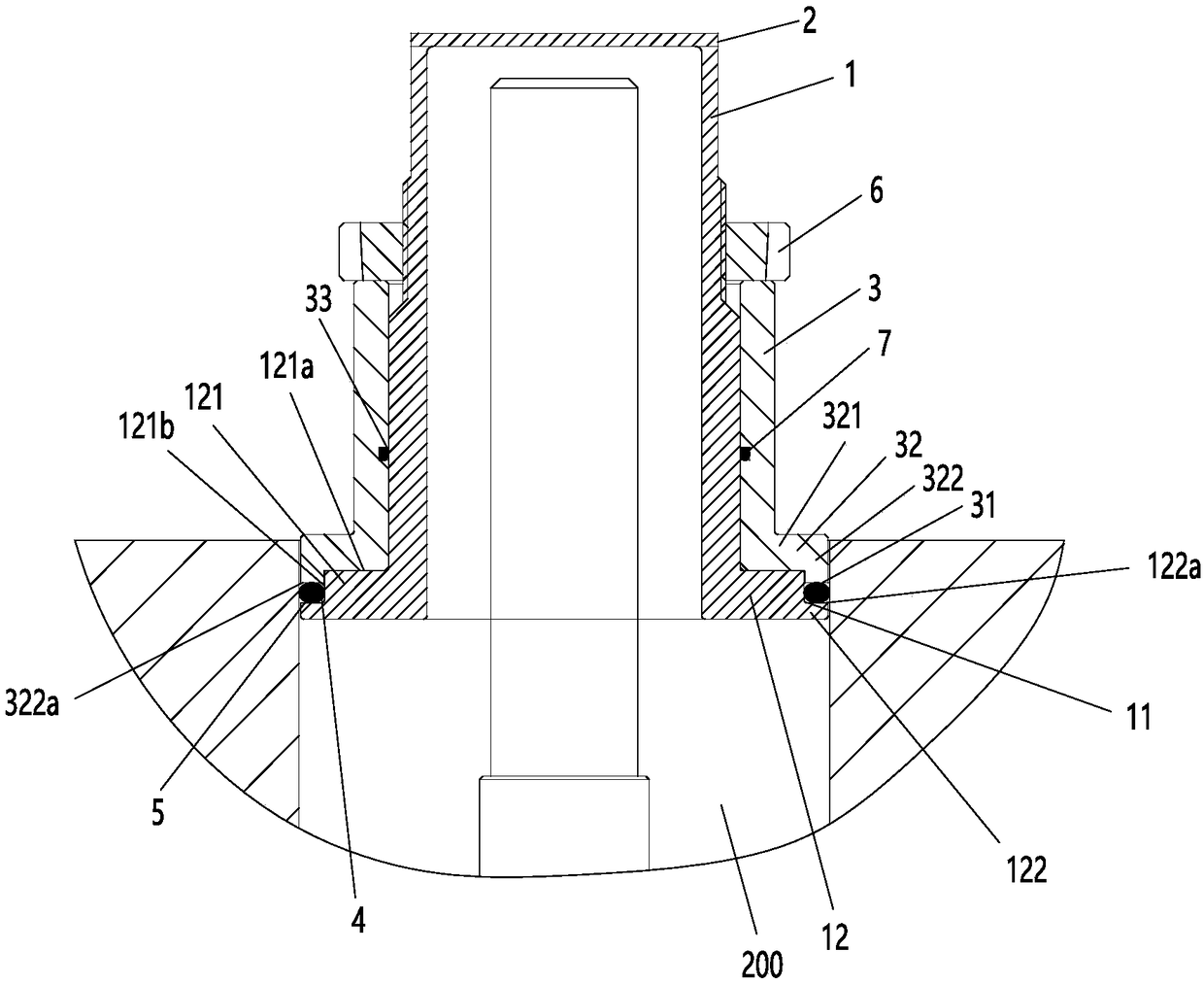

[0024] Such as figure 1 As shown, the figure schematically shows that the sealing structure for maintenance of the pebble bed high temperature reactor device includes a cylinder body 1 , a sealing end plate 2 , a pressure sleeve 3 , an annular groove 4 , a sealing component 5 and a tightening and pressing component 6 .

[0025] In the embodiment of the present application, the lower end of the cylinder body 1 is installed coaxially with the base shaft hole in the pebble bed high temperature reactor device. It is easy to understand that the cylinder body 1 is a hollow cylindrical structure.

[0026] An opening is formed at the upper end of the cylinder body 1 .

[0027] The sealing end plate 2 is arranged at the opening of the cylinder body 1 . That is to say, the setting of the sealing end plate 2 mainly plays the role of sealing, that is, it seals the opening of the upper end of the cylinder body 1 and plays the role of sealing.

[0028] It should be noted that the so-call...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com