Method for detecting axis parts and device thereof

A technology of shaft parts and detection methods, applied in the field of detection, can solve the problems of many human errors, difficulty in realizing high-precision product detection requirements, and inability to guarantee accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention is described in further detail below in conjunction with embodiment and accompanying drawing, but the embodiment of the present invention is not limited thereto.

[0075] Implementation one:

[0076] A method for detecting shaft parts, comprising the following steps:

[0077] Image acquisition - image correction - sub-pixel edge detection - sub-pixel corner detection - image stitching - diameter detection

[0078] Step 1. Image Acquisition

[0079] Through the movement of the camera, the camera is used to take images of each part of the shaft parts to be detected that need to be detected.

[0080] Step 2. Image correction

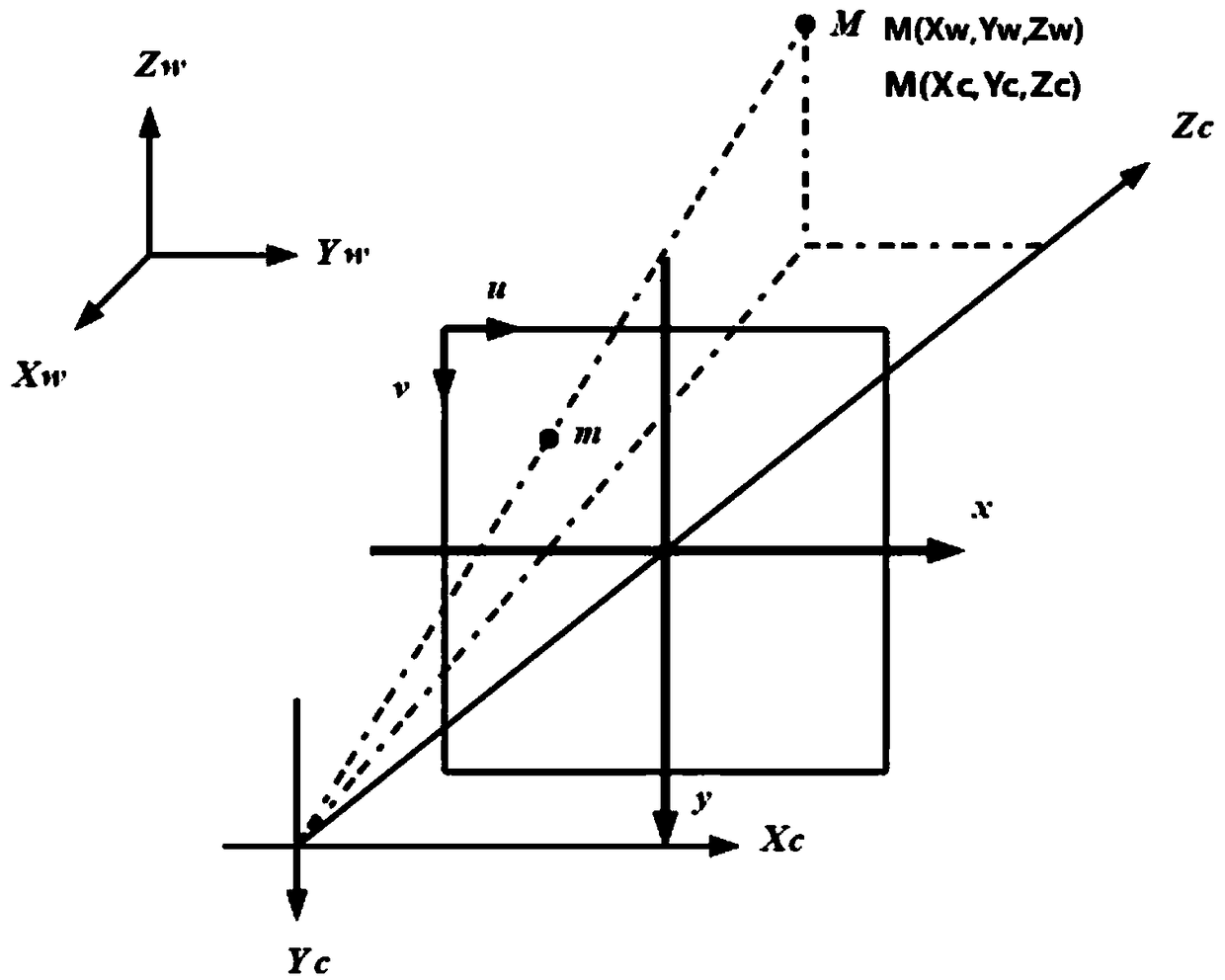

[0081] (1) Camera calibration

[0082] Calibration steps:

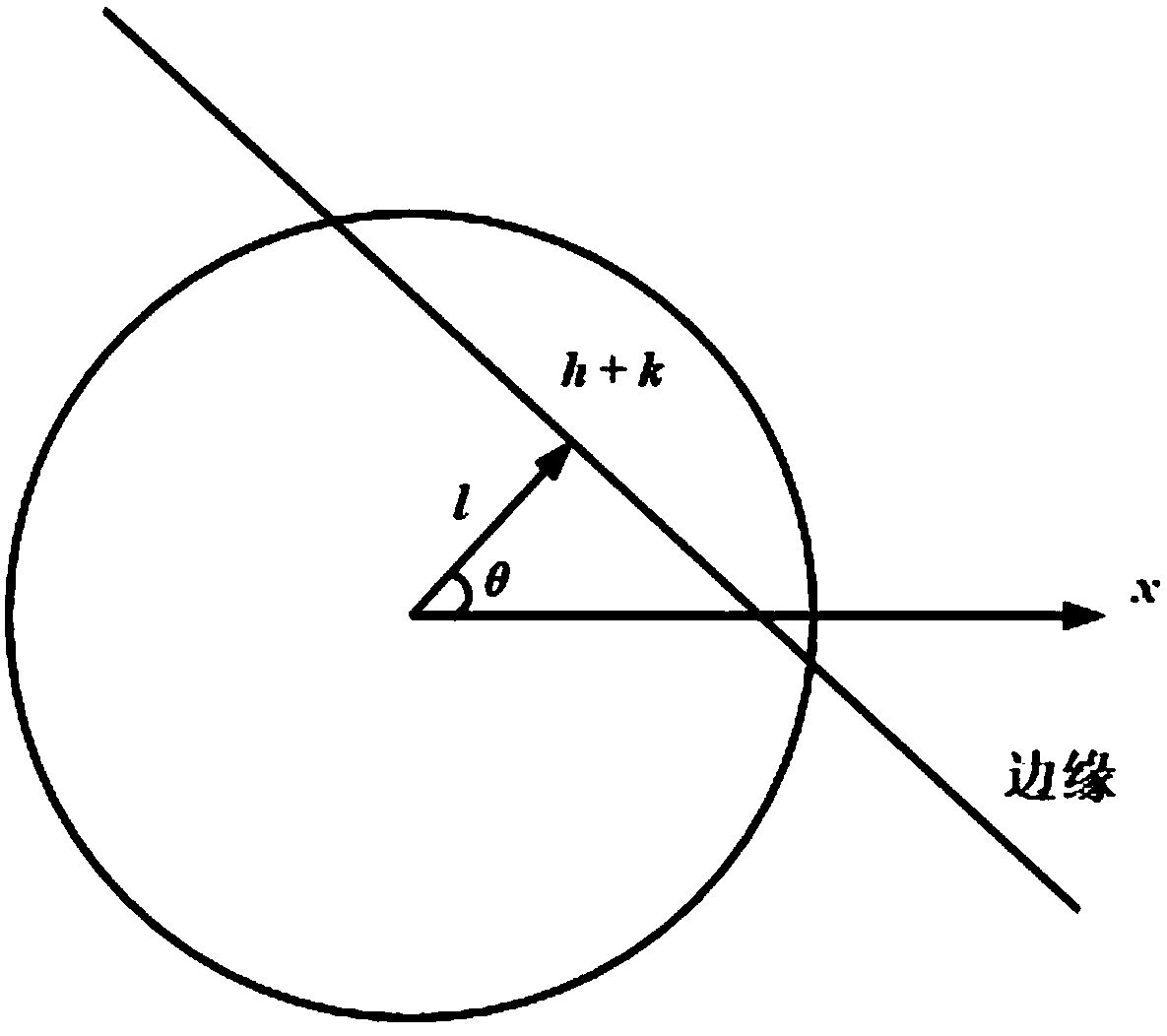

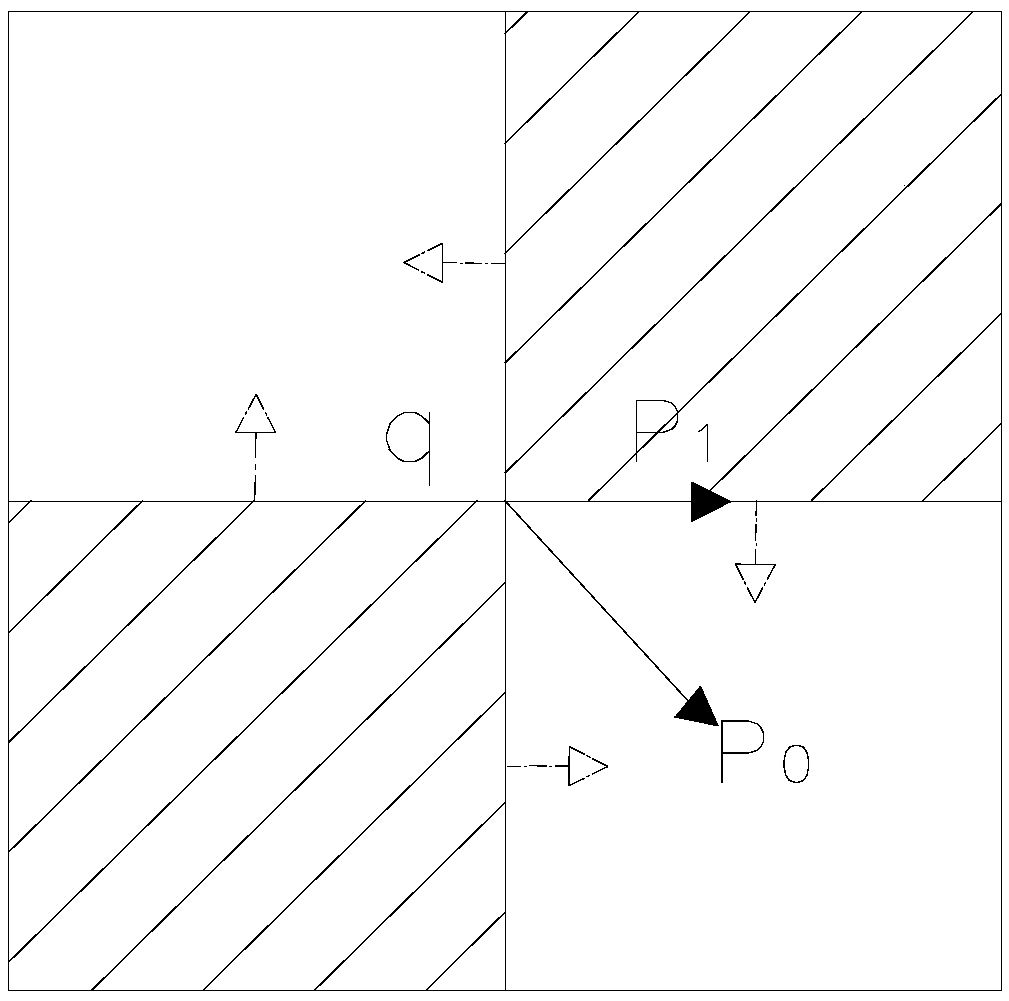

[0083] What the present invention selects for use is the chessboard grid as calibration plate. The calibration board is a 12×9 checkerboard grid, and the size of each grid is 20mm×20mm. Select an appropriate objective lens distance, and take multiple shots of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com