Test platform for cooler detection

A technology of coolers and test benches, which can solve the problems of single function of water detection, high labor intensity and heavy workload, etc. , to achieve the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with specific drawings and embodiments.

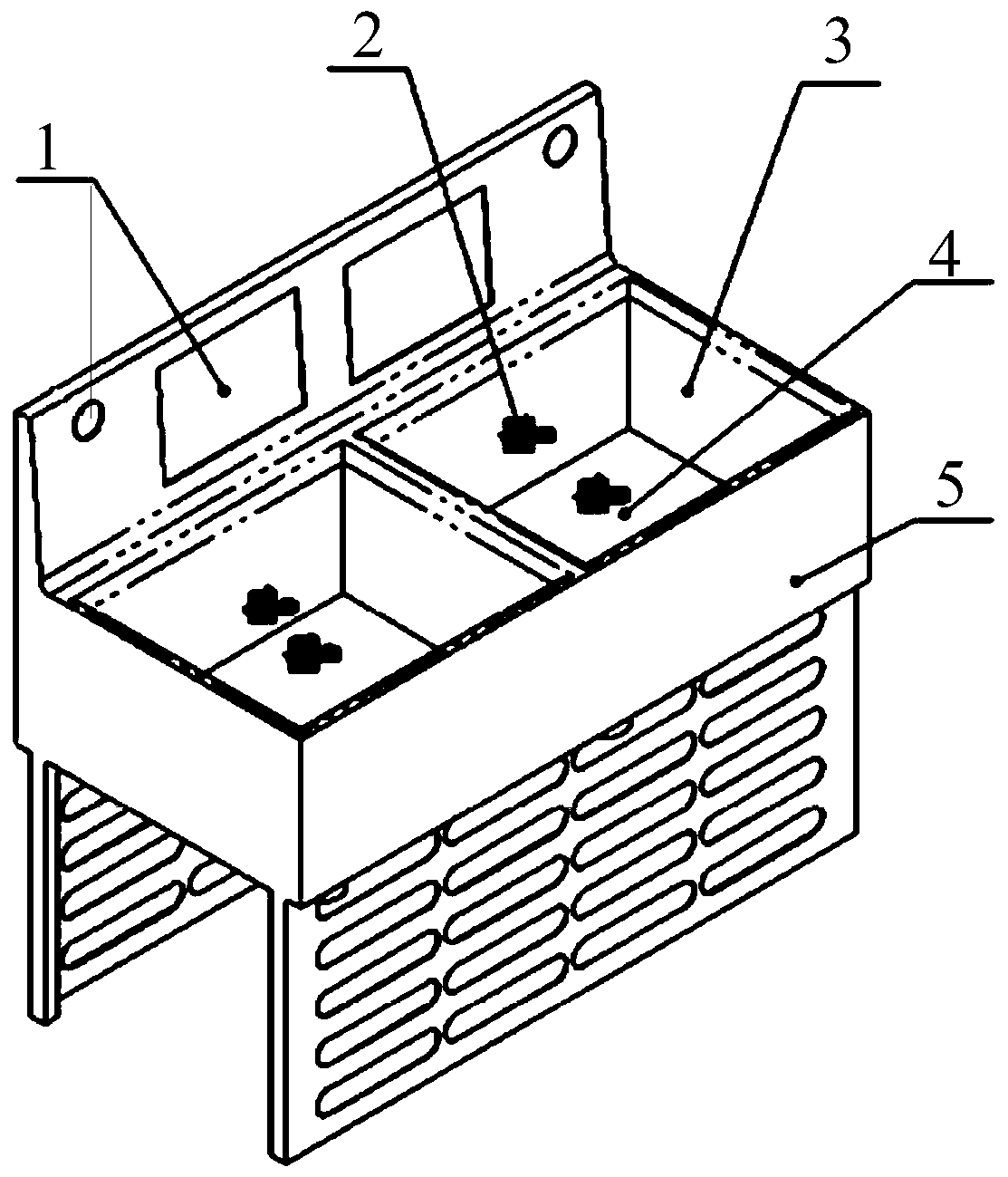

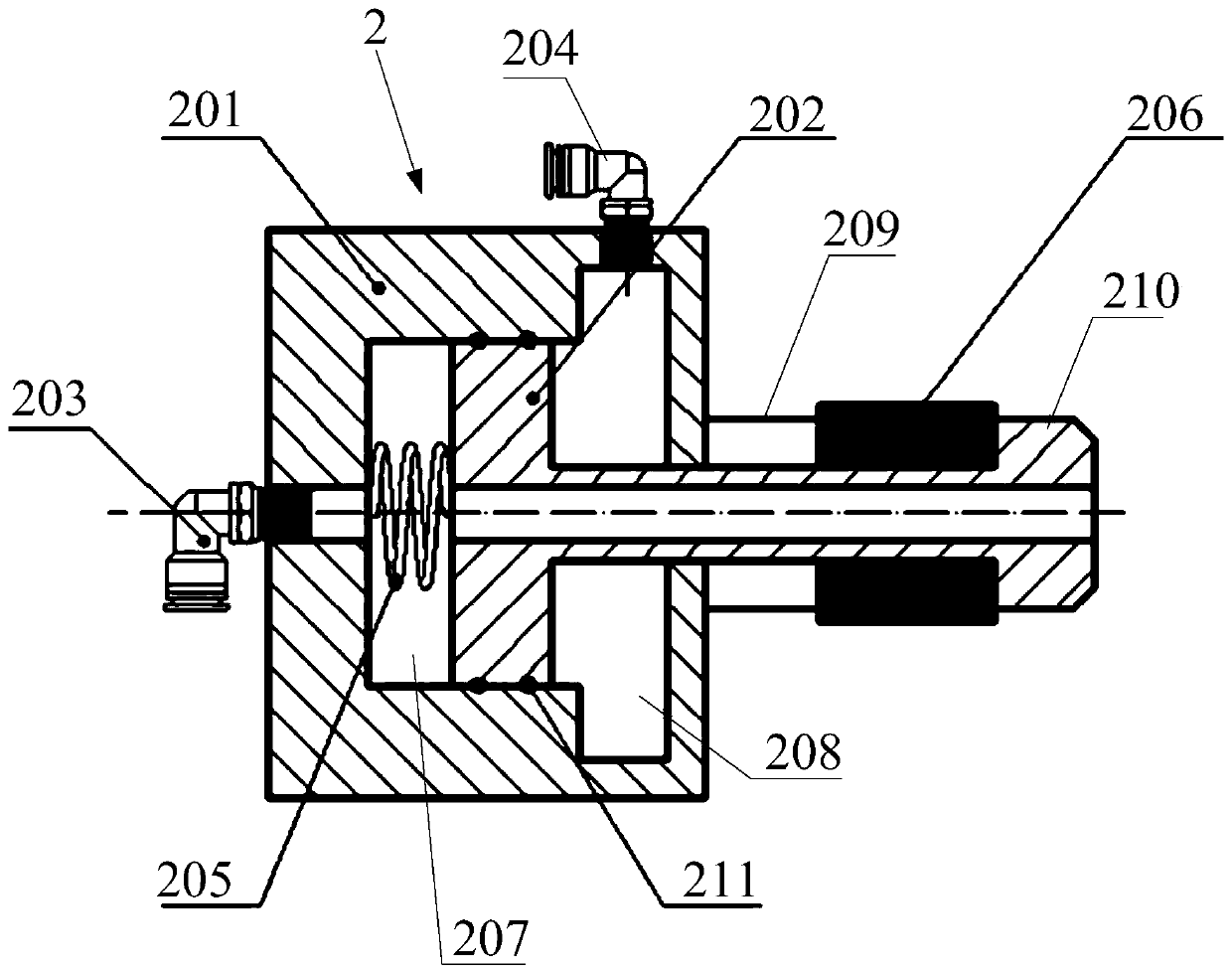

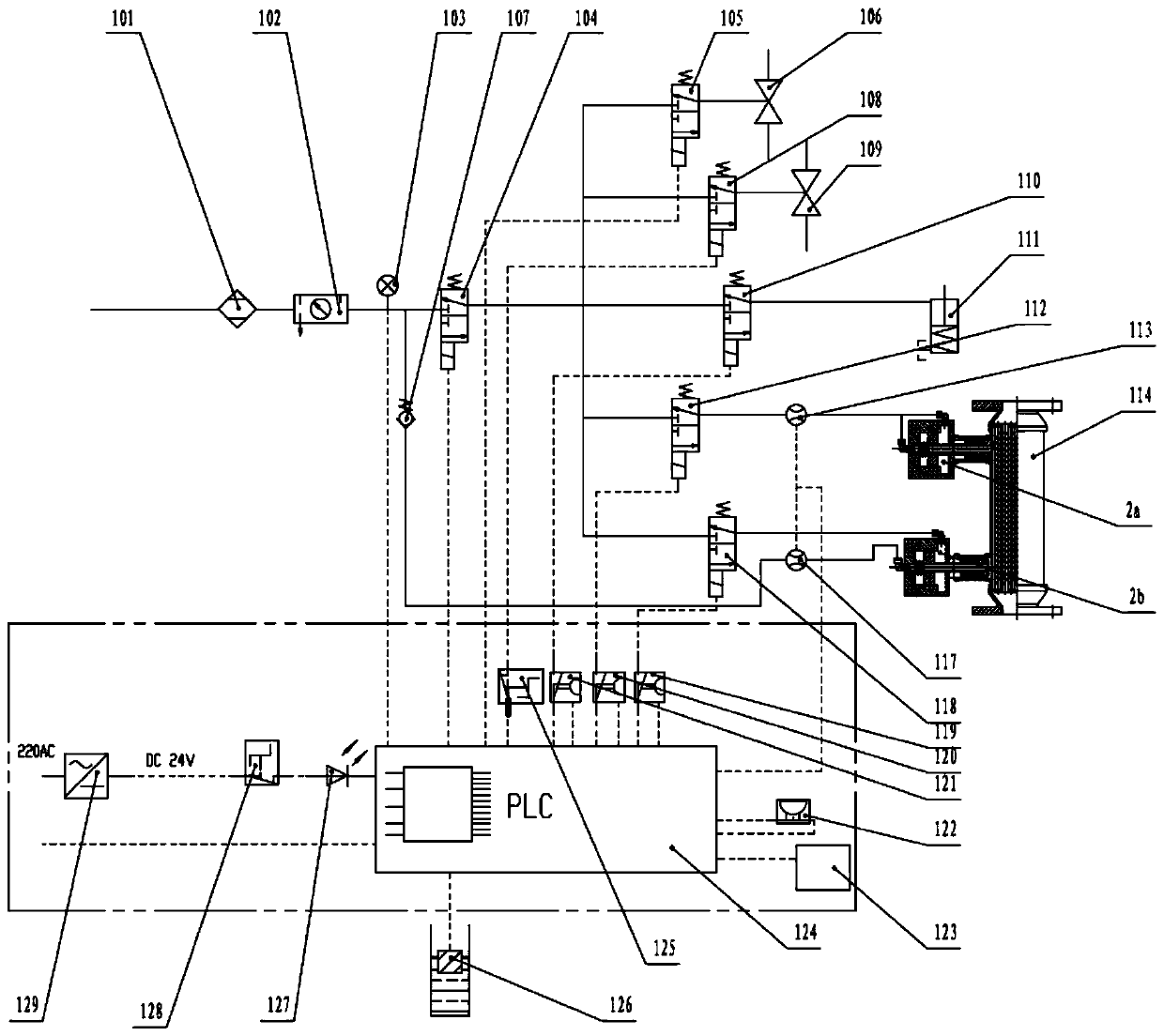

[0042] Such as figure 1 As shown, a test bench for cooler detection proposed by the present invention includes a control system 1, an air control chuck 2, a water tank 3, a lifting platform 4, and a frame 5;

[0043] The water tank 3 is installed in the frame 5; in order to improve the test efficiency, two water tanks 3 can be set in the frame 5; the cooler is placed in the water tank 4 for testing, after the cooler is ventilated, if the cooler has leakage, then in Bubbles can be observed in the water, which is convenient for the tester to observe;

[0044] The water tank 3 can be manually filled and drained, for example, a faucet for water injection is provided on the upper part, and a drain is provided at the bottom; more preferably, the water tank 3 can also realize automatic water filling and automatic drainage, for example, the water tank 3 is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com