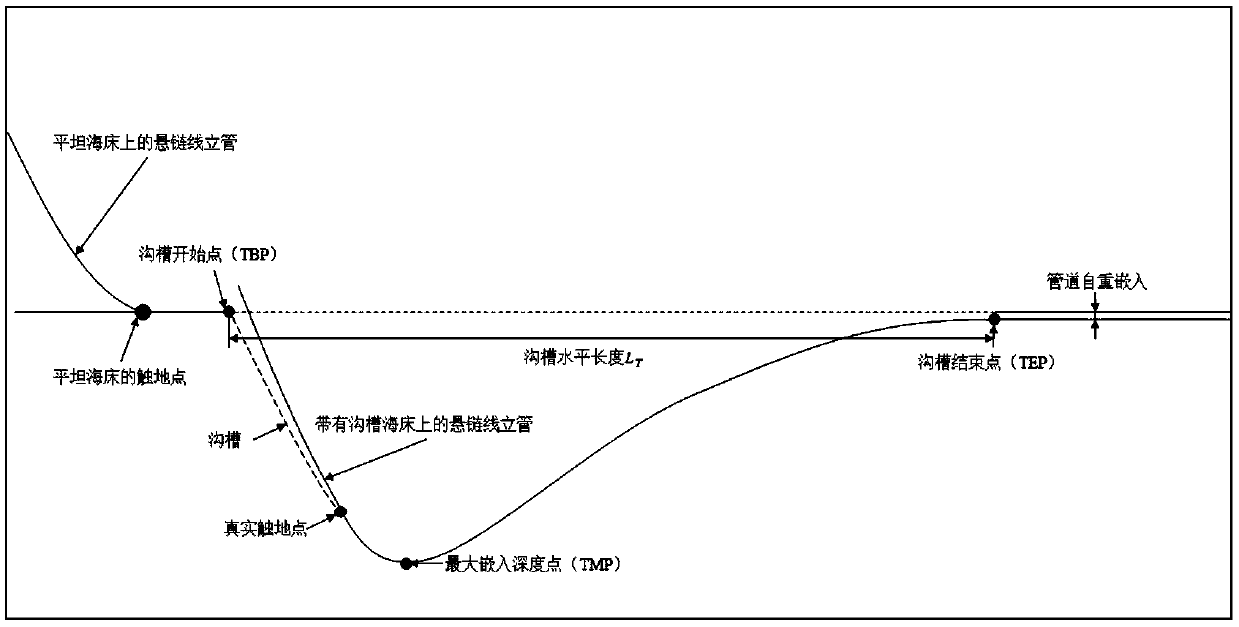

Groove analysis method for forming steel catenary standpipe ground contact point area

A technology of steel catenary and analysis method, which is applied in the field of analysis, can solve problems such as the growth of simulated trench calculations, and achieve the effects of improving the calculation time, improving the overall design process, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0067] 1. Because the calculation time of using the conventional method to simulate the trench is too long, the influence of different parameters on the shape of the trench is studied, and the suggested value of the nonlinear soil parameter that accelerates the formation of the trench is proposed.

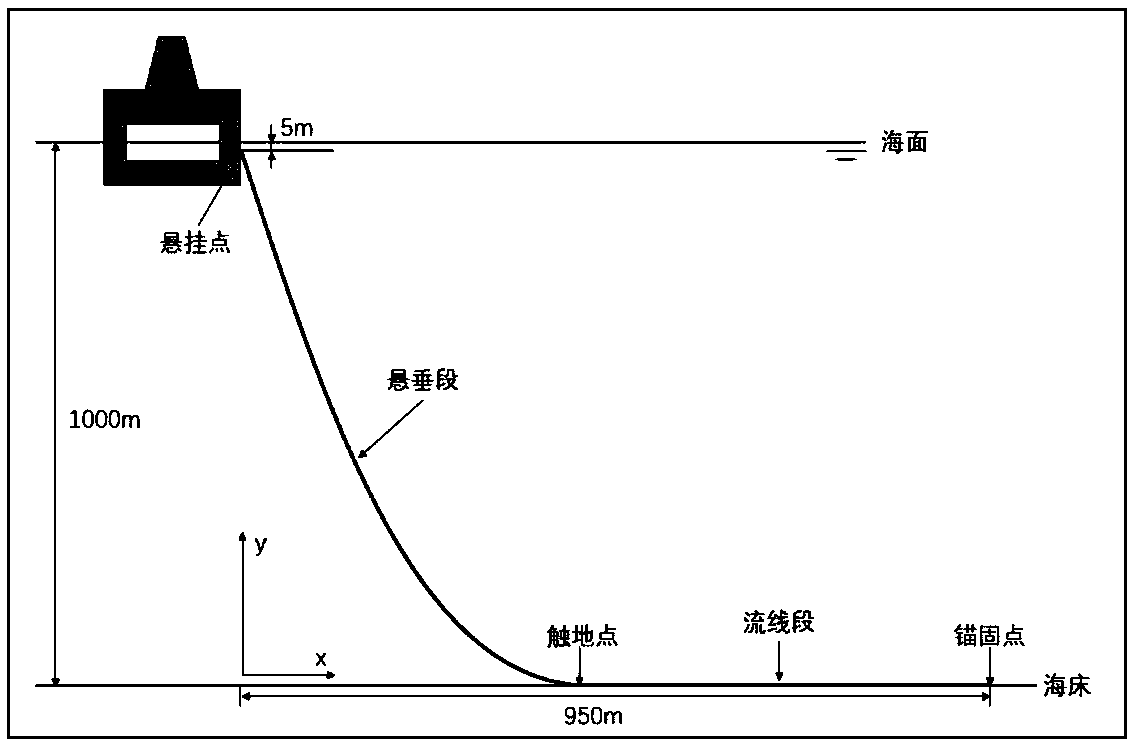

[0068] 1) Use Orcaflex to establish the model of the steel catenary riser, floating body and seabed system, that is, the riser-trough model.

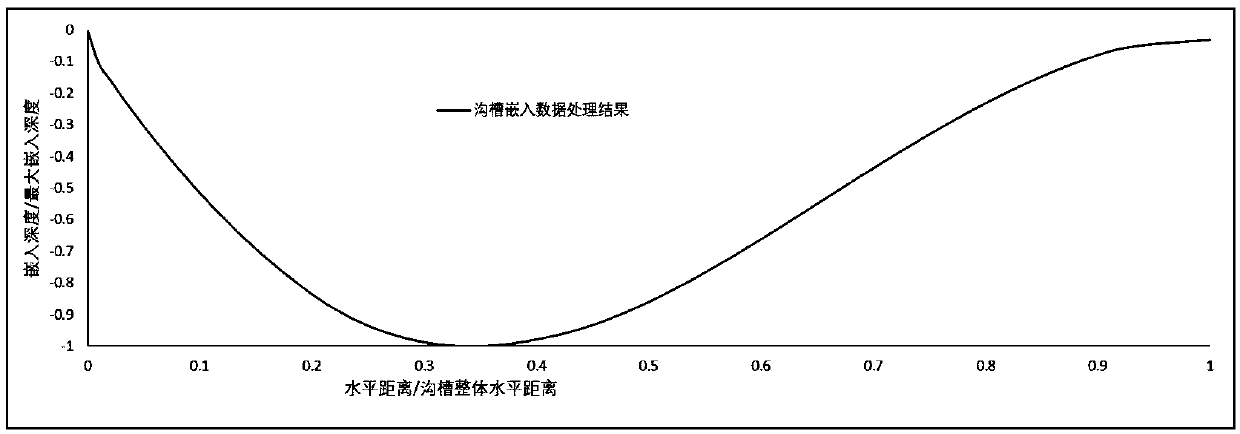

[0069] 2) The nonlinear soil parameters are studied by means of control variables. Compared with the basic working conditions, each calculation condition only changes one effective parameter of the nonlinear soil parameters. By comparing the calculation results, the impact of the nonlinear soil parameters on the trench The effect of shape.

[0070] 3) Under a variety of calculation conditions with different values of nonlinear soil parameters, the dynamic response analysis of the riser-groove model is carried out, the value of the groove e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com