On-line Diagnosis Method of Air Leakage Fault of Sintering Machine

A diagnostic method and technology for sintering machines, which can be used to detect the appearance of fluids, furnaces, and instruments at leakage points, and can solve the problems of exhaust fan energy waste, complex structure, and air leakage, and achieve low occupancy of computing resources and memory resources. The effect of low computational complexity and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

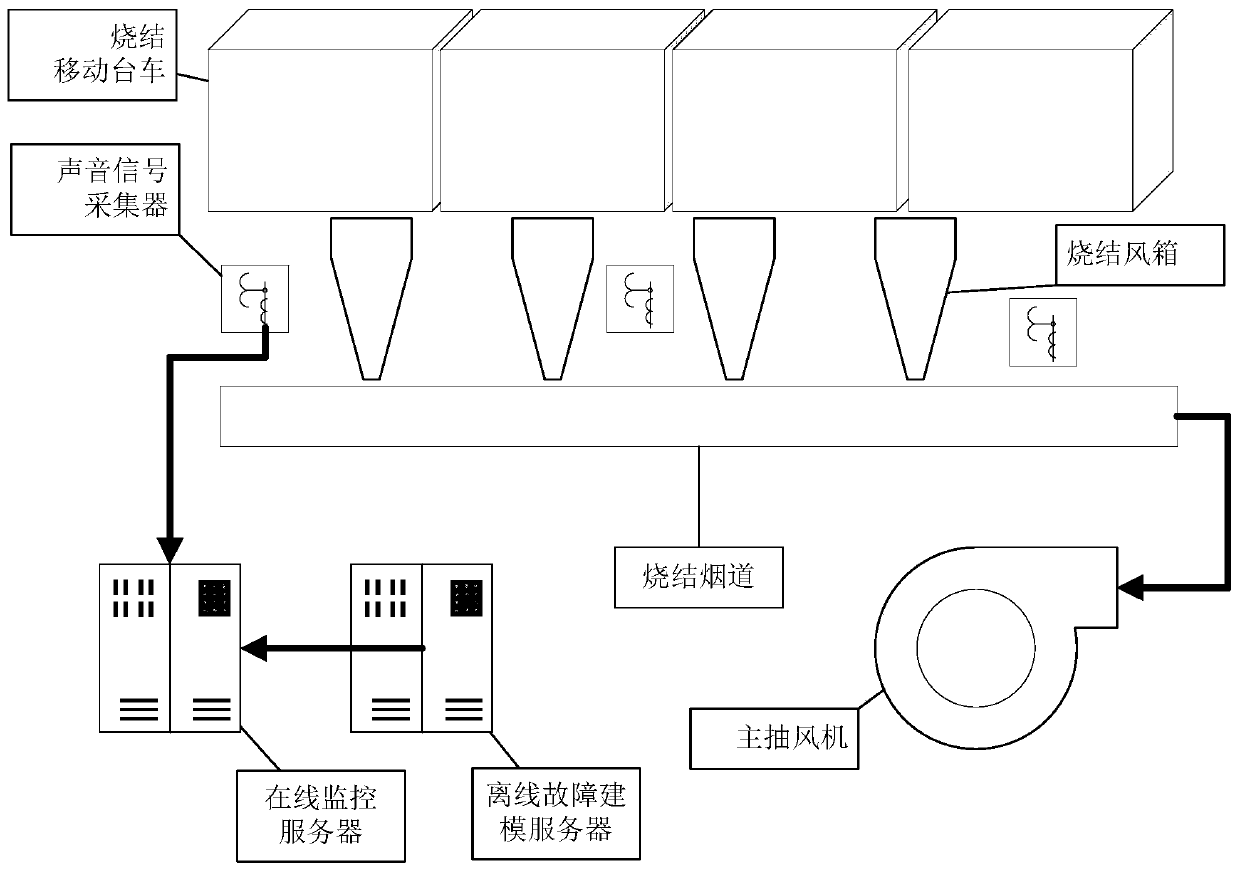

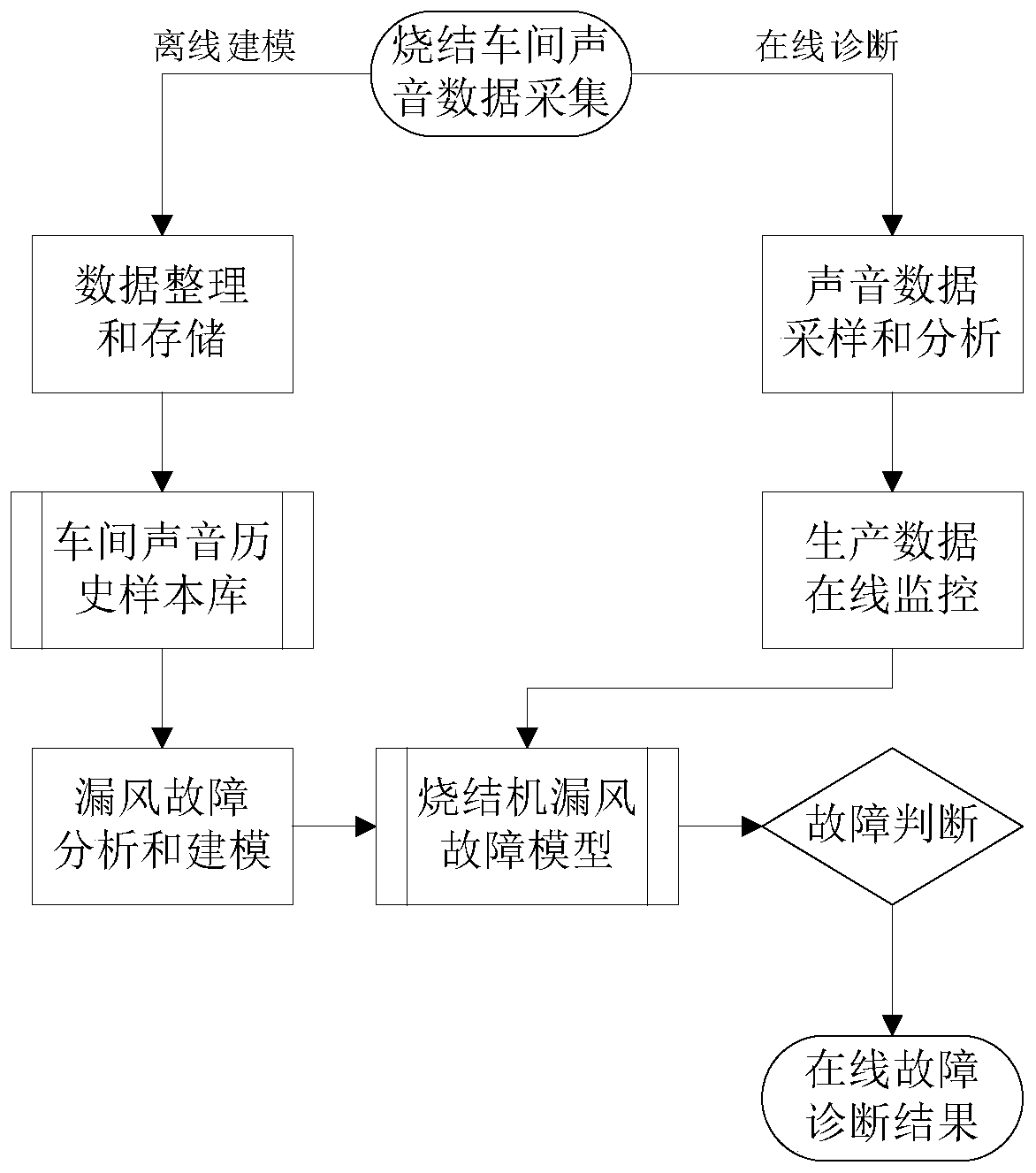

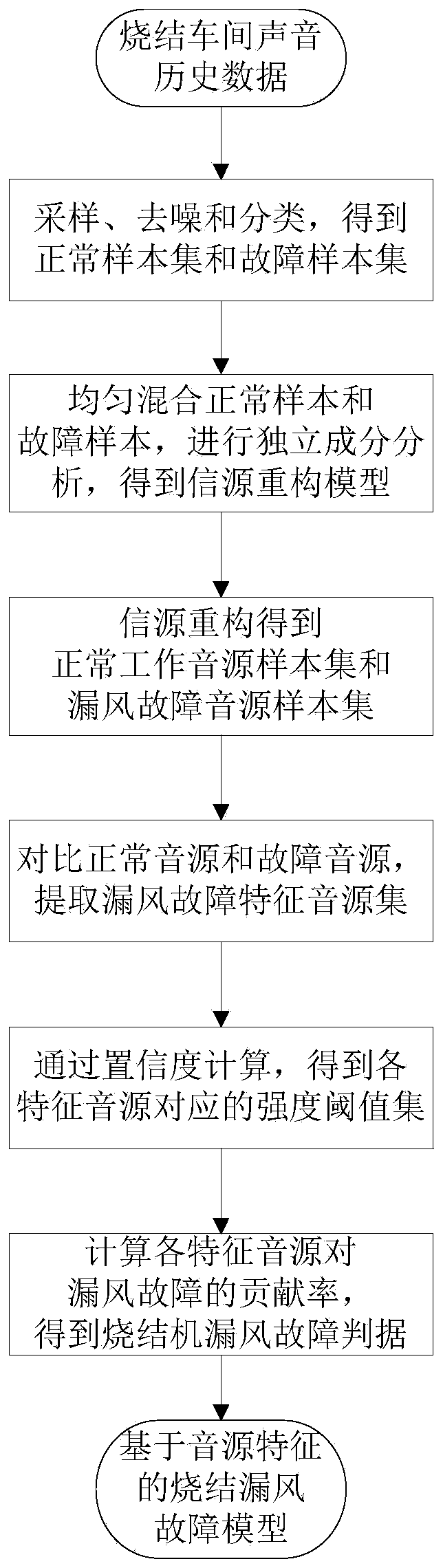

[0047] The present invention aims to provide an online diagnosis method for air leakage faults of sintering machines, which realizes comprehensive monitoring of various air leakage conditions of sintering machines through online collection and analysis of sound signals at the sintering production site. Due to the complex structure of the sintering machine, it will cause frequent and frequent air leakage failures. In other words, the sintering machine is prone to air leakage faults, but because the fault involves the airtightness of the structure, for large equipment, there are many fault points and fault causes with different mechanisms, so it is difficult to correct the air leakage of the sintering machine Comprehensive fault monitoring. The sound signal has the characteristics of fast propagation speed and not easy to be blocked. According to the long-term production experience, an important phenomenon of air leakage failure of the sintering machine is the howling sound caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com