A multi-stage constant-pressure compressed air energy storage device

A technology of compressed air energy storage and compression tube, which is applied in pump devices, mining devices, non-variable capacity pumps, etc. Efficiency optimization and improvement, less energy consumption, and higher requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

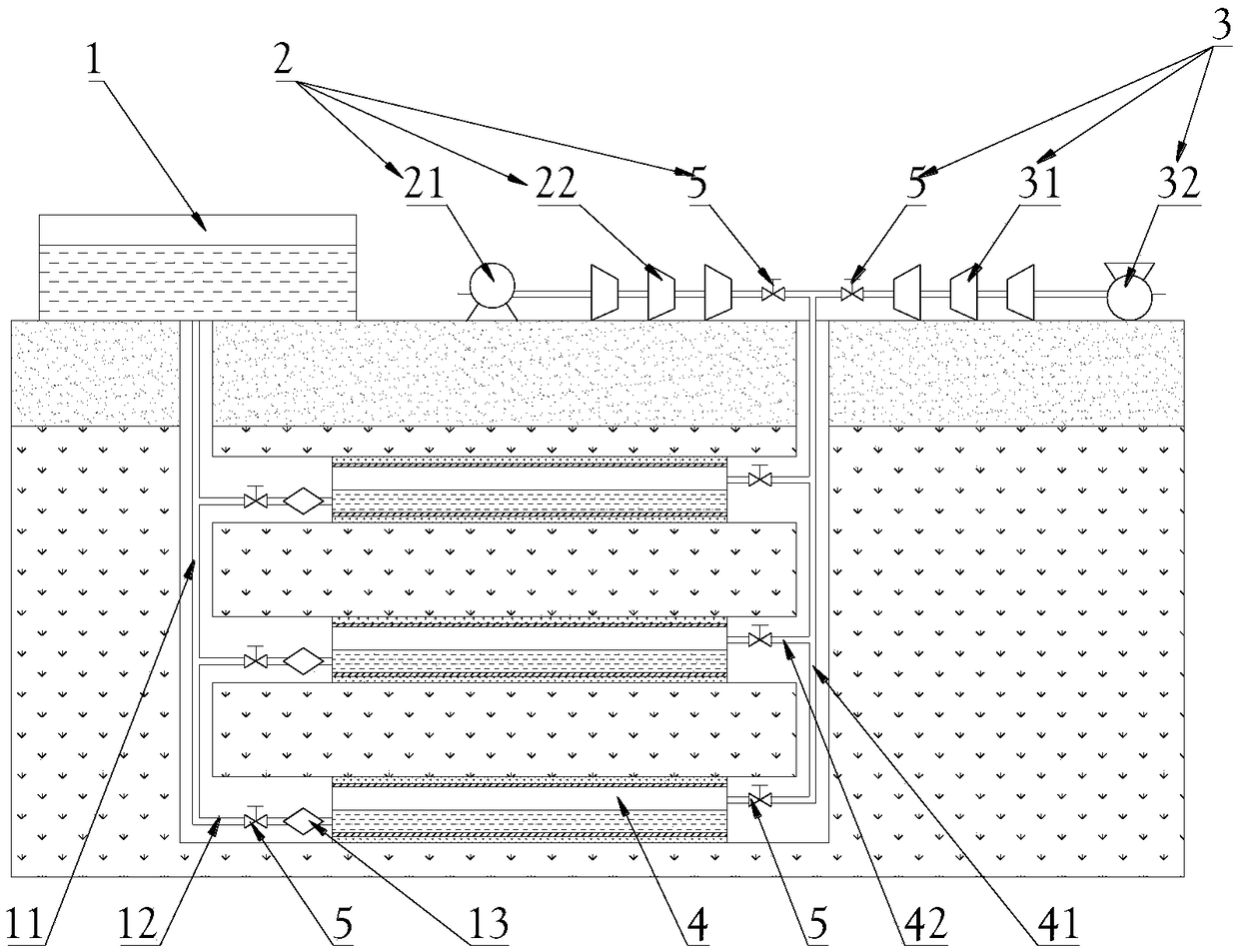

[0026] Such as figure 1 As shown, a multi-stage constant pressure compressed air energy storage device includes a water storage tank 1, a compression pipeline 2, a power generation pipeline 3 and at least two storage chambers 4 with height differences along the vertical direction; the water storage There is a height difference between the pool 1 and the storage chamber 4 in the vertical direction, and the reservoir 1 is connected to the storage chamber 4 through a water pipe 11 arranged downwards, thereby providing different water pressures for the storage chamber 4 at different heights; each storage chamber 4 The upper part is connected to the water pipe 11 through the water distribution pipe 12, and each water distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com