Turbogenerator compound condensate thermodynamic system

A steam turbine generator, thermal system technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve problems such as affecting the surrounding environment, workers' health, and water waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

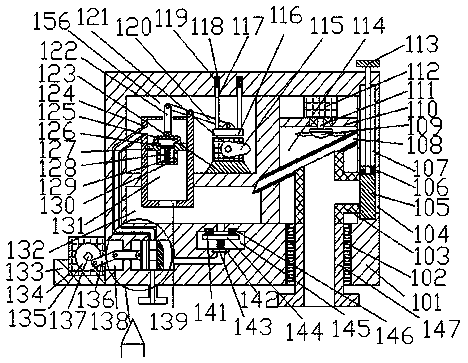

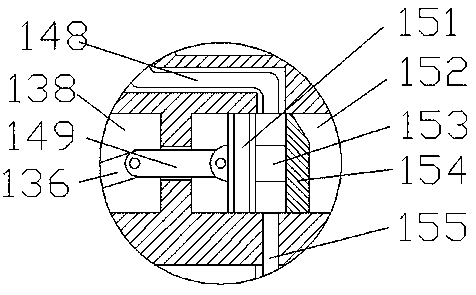

[0014] Such as figure 1 and figure 2As shown, the steam turbine generator composite condensate thermal system of the present invention includes a frame body 101 and a water storage chamber 132 extending left and right inside the frame body 101. A pumping chamber 156 is provided above the water storage chamber 132. The right side of the pumping chamber 156 is provided with a cooling chamber 114 extending up and down, and the cooling chamber 114 is provided with a condensing water collecting pipe 108 inclined downward to the left, and the left end corner of the condensing water collecting pipe 108 extends into the water storage chamber 132, the bottom end of the cooling chamber 114 is connected with a threaded port 102 extending up and down, and the threaded port 102 is threadedly connected with a threaded pipe 147 extending up and down and extending out of the bottom end of the frame body 101. The threaded pipe 147 The top end surface is provided with a top end extending into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com