Fireproof bridge-cutoff aluminum alloy casement window

A technology of aluminum alloy and casement windows, which is applied in fire doors, windows/doors, door/window applications, etc., and can solve problems such as poor contact strength, poor flame retardancy and fire resistance, and poor water-repellent sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

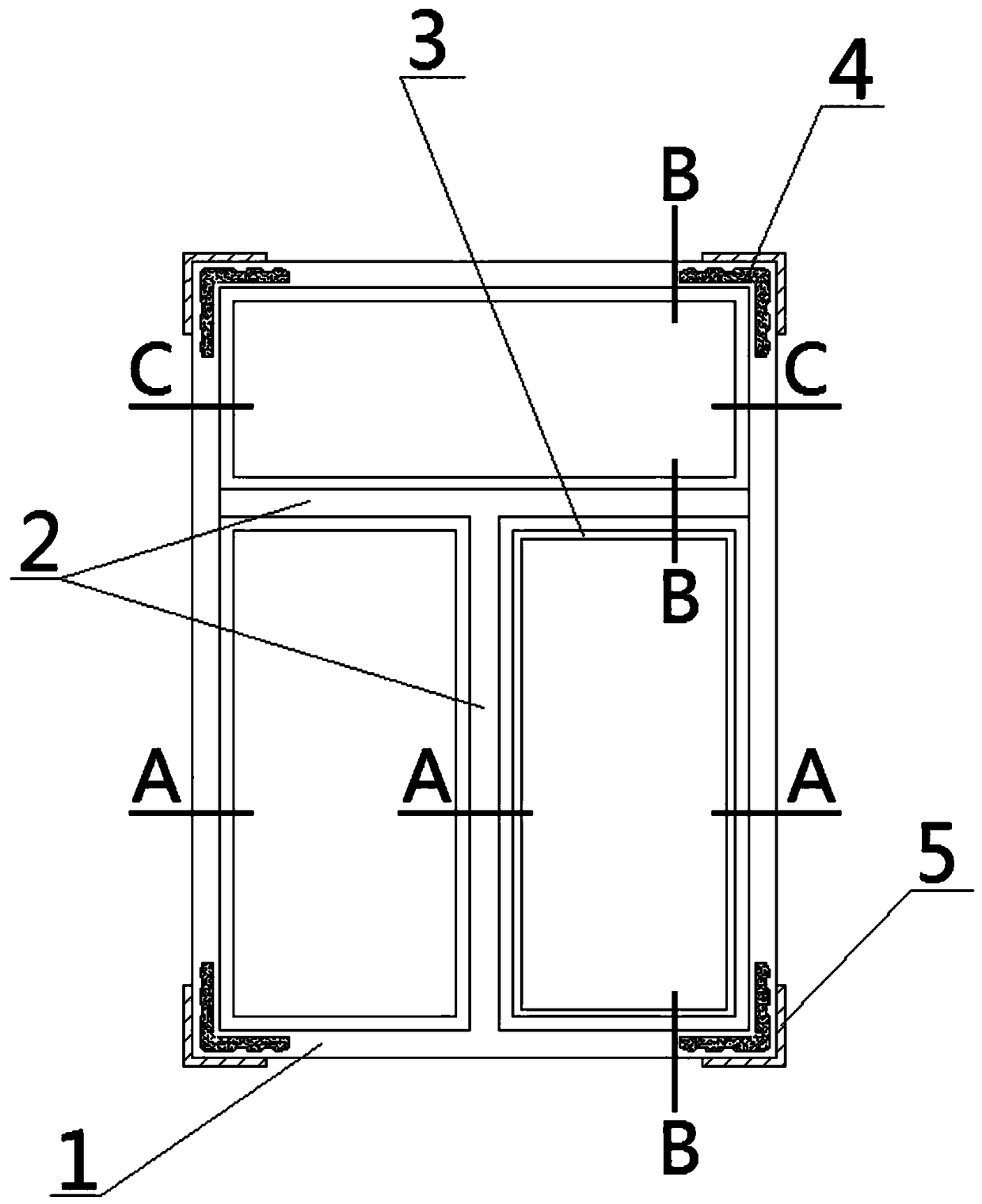

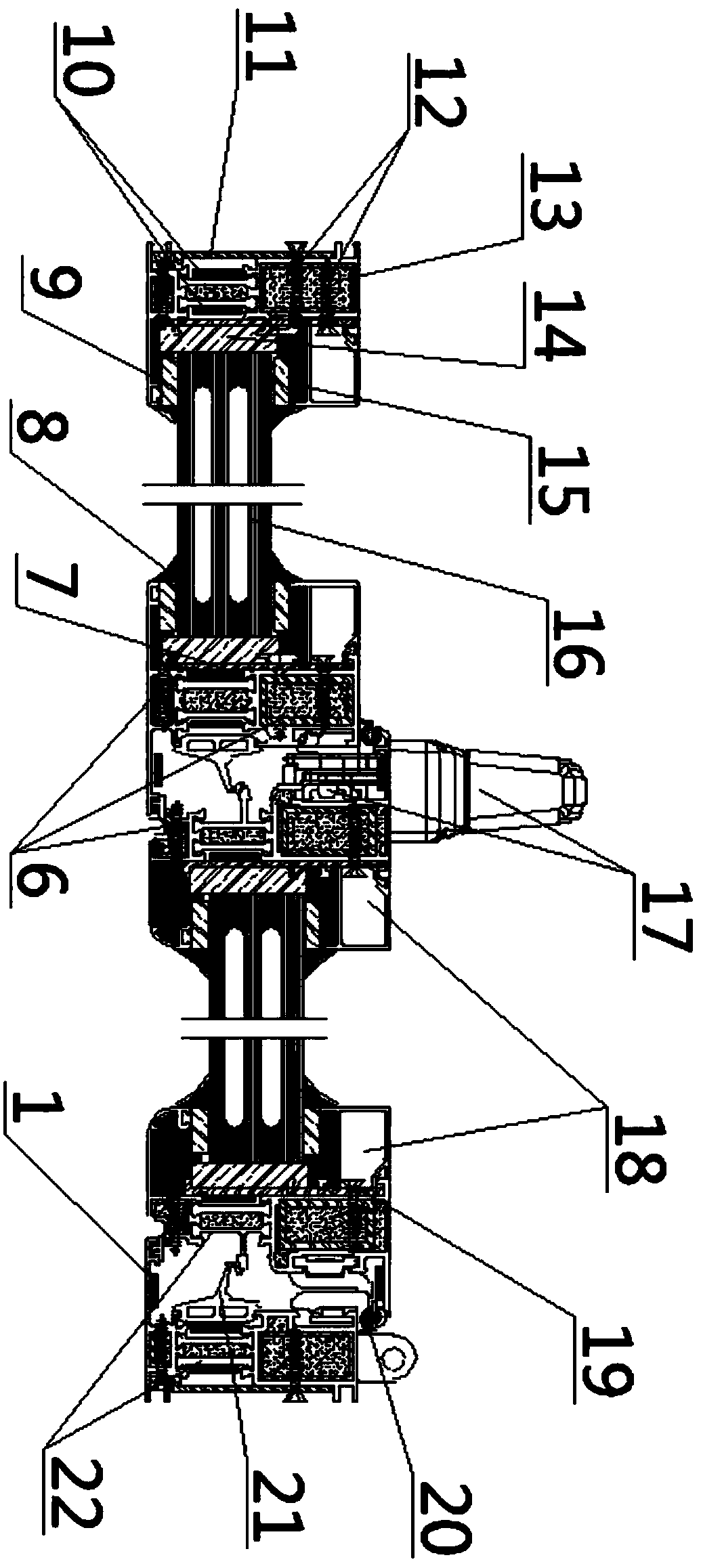

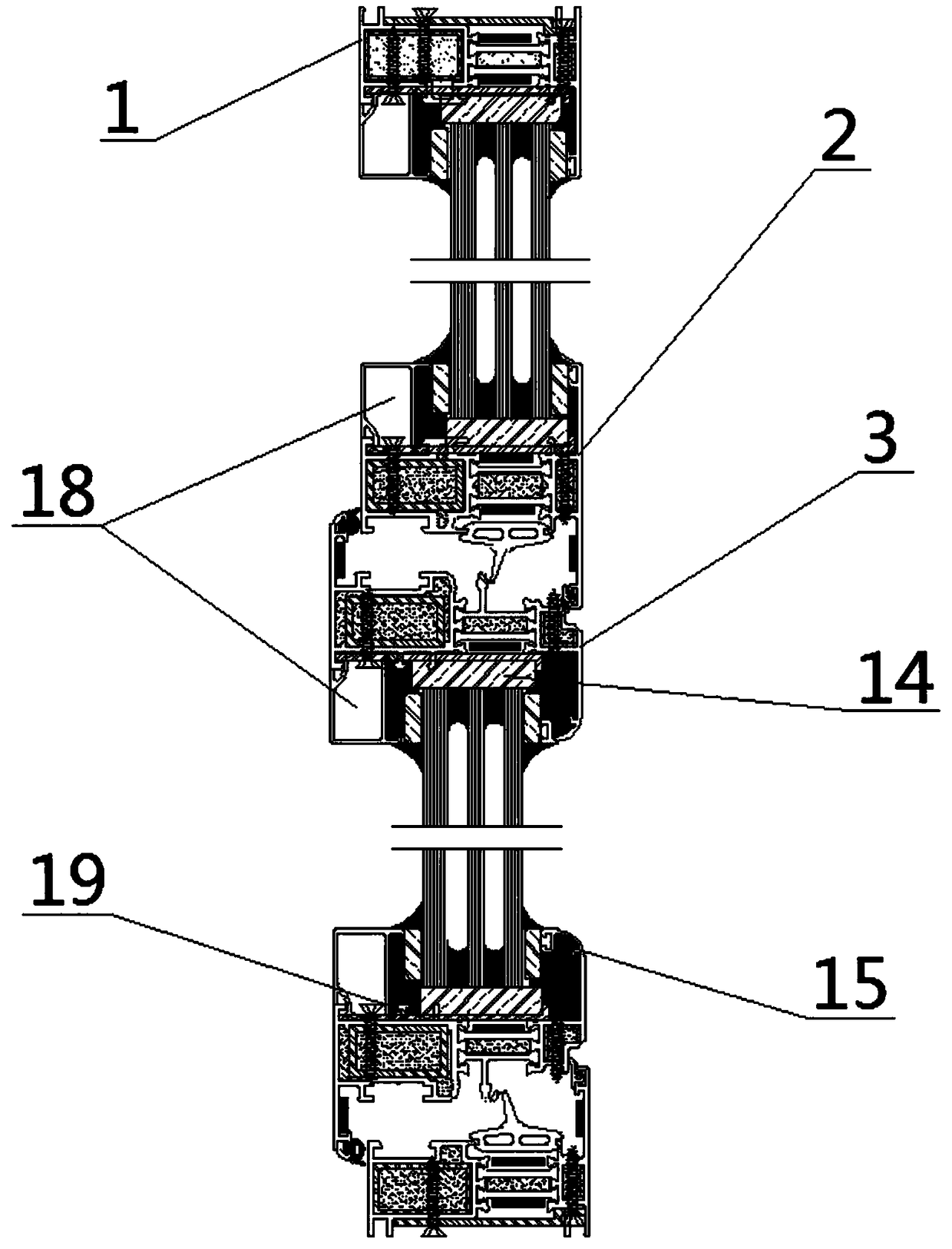

[0015] See the accompanying drawings: a kind of fire-proof broken bridge aluminum alloy casement window, which is characterized in that it includes an inward opening sash (3), a solid glass sash bead (18), a window frame (1), a window center (2), and a corner bracket (4), heat-insulating and fire-proof glass (16), flame-retardant sealing strip (20), flame-retardant water-retaining strip (21), locking device (17), glass-solid steel support (7), outer frame reinforced steel sheet (11), cavity steel lining (6), fan reinforced steel sheet (19), steel lining corner connecting piece (5), stainless steel screw (12), glass peripheral gap piece (15), refractory glass spacer (14) ), fireproof expansion strip (10), fireproof sliver (9), cavity filling mud (13) and fireproof sealant (8), the inside and outside of the four corners of the window frame (1) and the wall contact area are installed with corner codes ( 4), the outer frame of the window frame (1) is installed and fixed with the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Refractory temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com