High-F-value oligopeptide and preparation method thereof

An oligopeptide and pH value technology, applied in the field of high F value oligopeptide and its preparation, can solve the problems of less sample loading, difficult process amplification, difficulty in large-scale production, etc., and achieve sufficient sources, low price, and high F value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

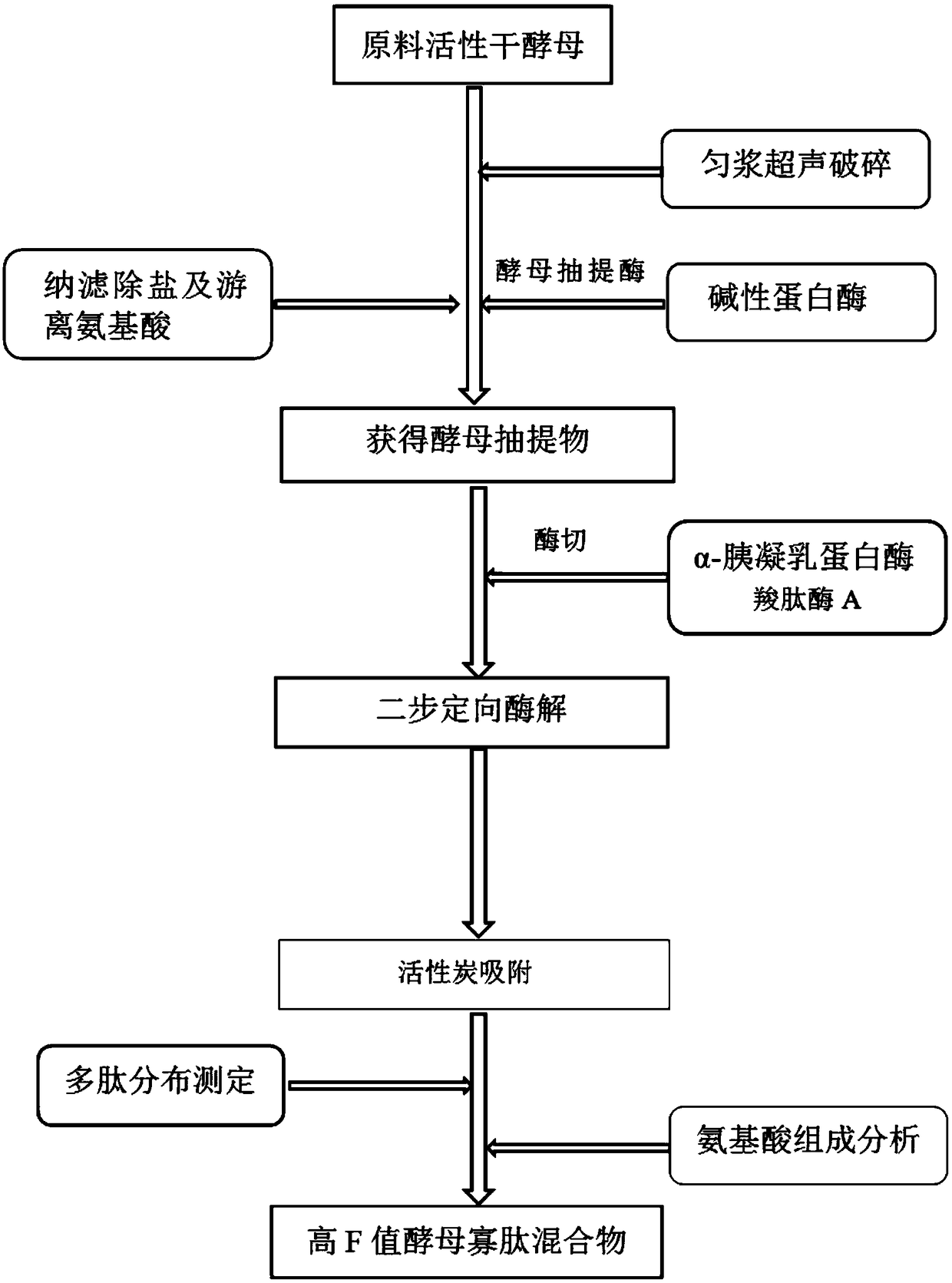

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 Preparation of yeast protein aqueous solution

[0054] Distilled water is added to the active dry yeast to form a yeast protein solution with multiple groups of certain solid content. The concentration can be selected from 160 to 210 g / L, and the solution is ultrasonically broken. The ultrasonic power is 300W, 350W, 400W or 450W, the ultrasonic time is 20min, and the time interval is 2s / 2s.

[0055] Taking the soluble protein in the supernatant after crushing as an index, with the strengthening of ultrasonic power, the degree of yeast fragmentation first increases and then tends to be flat. When the power reaches 400W, the degree of change in protein yield tends to be stable, so consider the issue of energy consumption. , choose 400W ultrasonic power for ultrasonic crushing.

[0056] Then select the ultrasonic power to be 400W, configure multiple groups of yeast protein solutions according to the above method, and ultrasonicate at 400W for 10min, 15min, 20...

Embodiment 2

[0058] Example 2 Preparation of Yeast Extract

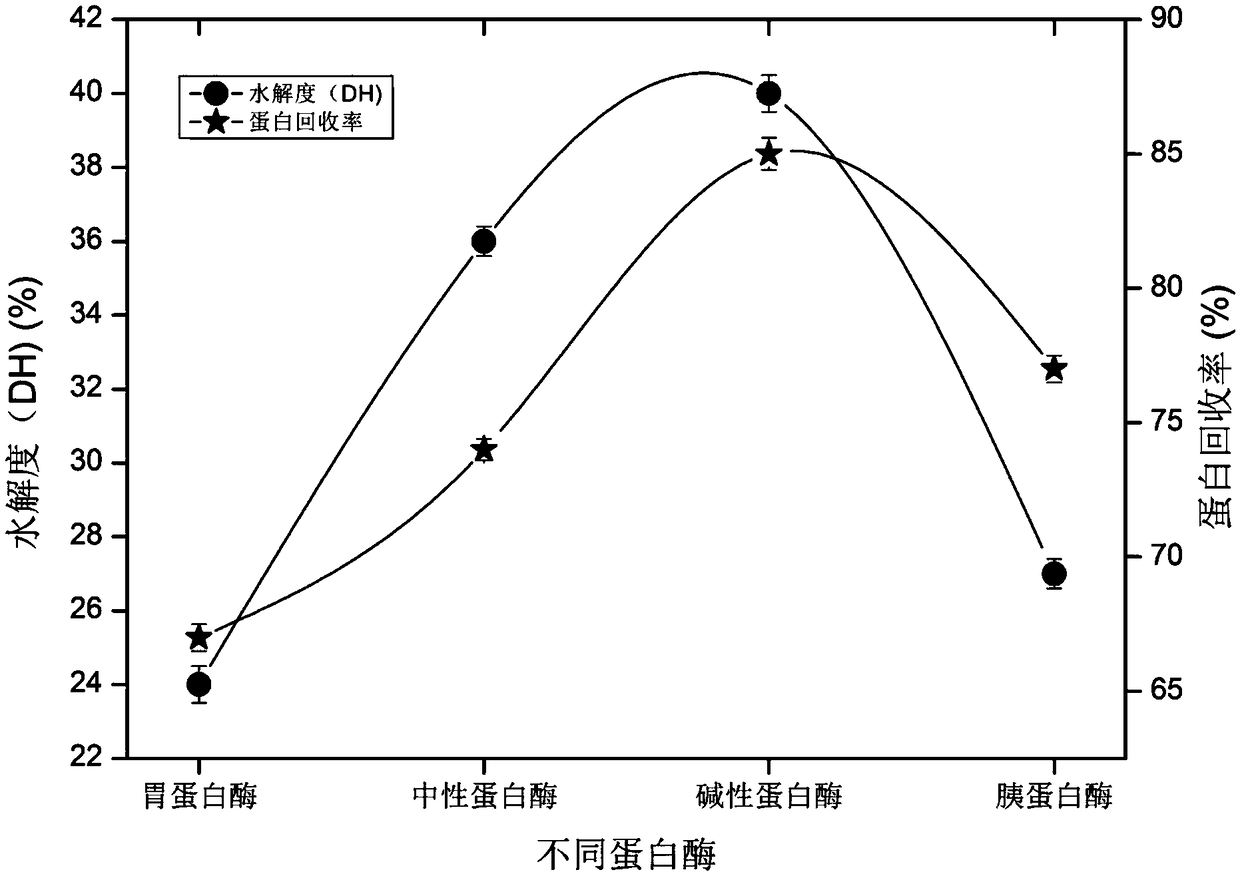

[0059] Configure the yeast protein solution according to the same steps as in Example 1, ultrasonicate the yeast protein solution at 400W for 20 minutes, and then use neutral protease, pepsin, alkaline protease and trypsin to enzymatically hydrolyze the solution, respectively set at a more suitable temperature and pH, the reaction time is 10h, and the amount of enzyme added is 500U·g -1 .

[0060] The enzymatic hydrolysis conditions are as follows:

[0061] Neutral protease: 40-50°C, pH=6.0-7.0.

[0062] Pepsin: 35-45°C, pH=1.5-2.5.

[0063] Alkaline protease: 45-55°C, pH=7.0-9.0.

[0064] Trypsin: 35-45°C, pH=7.5-8.5.

[0065] The result is as figure 2 shown by figure 2 It can be seen that the degree of hydrolysis of yeast protein by alkaline protease is the highest, followed by neutral protease, and the hydrolysis effect of pepsin is the lowest. At the same time, the protein recovery rate was positively correlated wit...

Embodiment 3

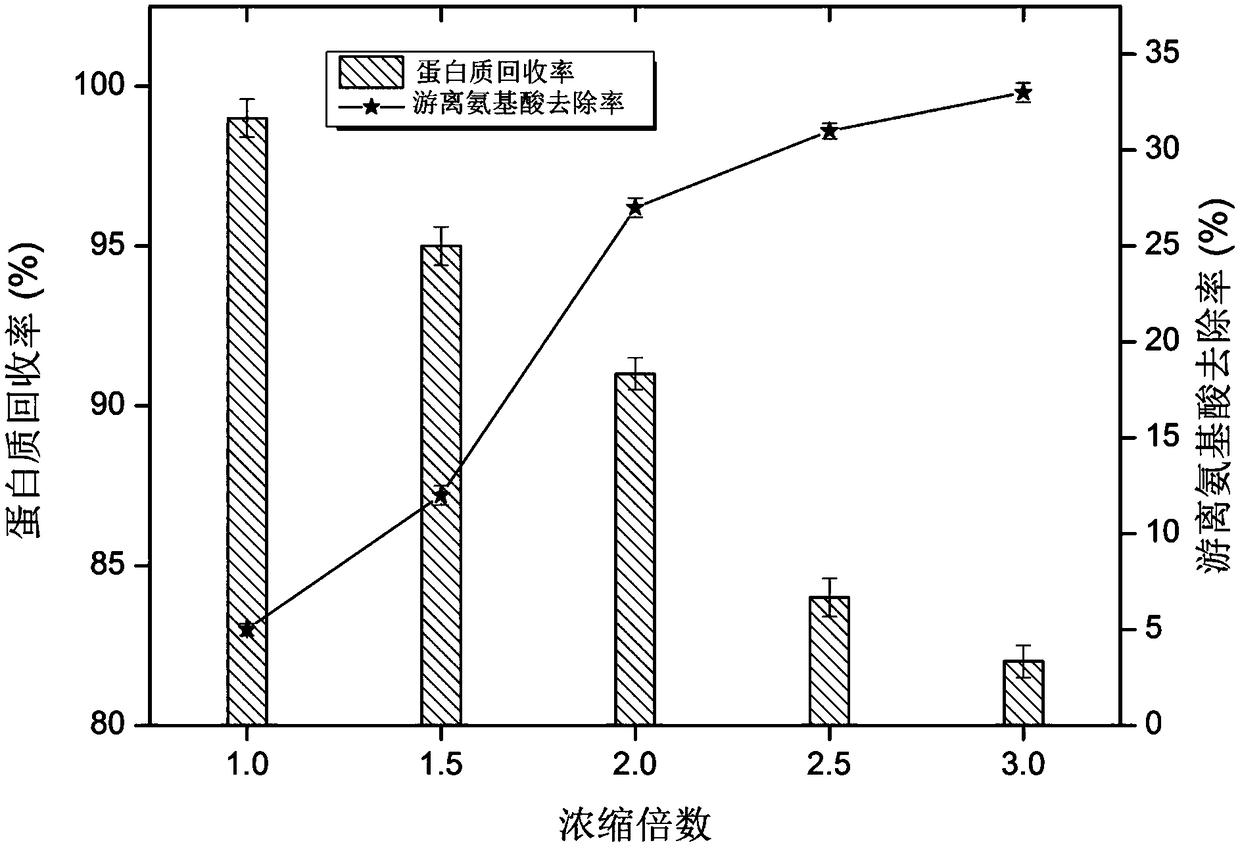

[0066] Example 3 Nanofiltration Concentration of Yeast Extract

[0067] On the basis of Example 2 (alkaline protease is used as the enzyme for active dry yeast extraction), the yeast extract was obtained, then the enzyme was inactivated in a boiling water bath for 15 minutes, and the supernatant was taken after centrifugation at 13000r / min for 15 minutes. Then get the supernatant and carry out the nanofiltration concentration operation. The nanofiltration condition is to adopt a PES roll-type membrane with a molecular weight cut-off of 500Da, the operating pressure is 2-4MPa, the initial pH of the yeast extract is 6.5-7.5, and the concentration ratio (volume of the cut-off liquid The ratio to the volume of the stock solution (1 / 1.5~1 / 3) is 1.0, 1.5, 2.0, 2.5, 3.0 times (concentration of 3.0 times means that the volume ratio of the retentate to the stock solution is 1 / 3, and other concentration ratios have similar meanings here ).

[0068] The result is as image 3 As shown, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com