Novel coil upper positioning plate

A technology for positioning plates and coils, which is applied to household components, household appliances, and other household appliances. It can solve problems such as tilting, uneven pouring upper surface, time-consuming and labor-consuming, etc., to speed up the process, save manpower and time, Reduce the effect of post-processing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further explained below in conjunction with the drawings.

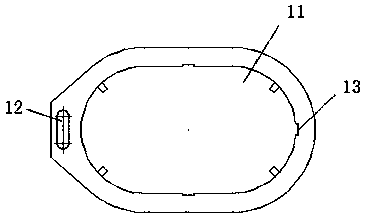

[0012] Such as figure 1 As shown, a novel coil upper positioning plate of the present invention includes a body 1 on which a pouring hole 11 and a measuring hole 12 are provided, and the measuring hole 12 is located on the left side of the pouring hole 11. A number of measuring ports 13 are opened on the inner wall of the pouring hole 11, and the measuring ports 13 are rectangular.

[0013] The pouring hole 11 and the measuring hole 12 both have a waist-shaped structure, and the line between the centers of the two arc sides in the pouring hole 11 is perpendicular to the line between the centers of the two arc sides in the measuring hole 12.

[0014] There are three measuring openings 13 respectively corresponding to the two straight sides of the pouring hole 11 and the arc side on the right side.

[0015] The invention adopts peripheral openings to facilitate the measurement of the pourin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com