Extrusion molding of anti-abrasive material for vehicle

A technology of extrusion dies and wear-resistant materials, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of poor control of feeding accuracy and low production efficiency, and achieve Improve precise control, improve production efficiency, and reduce the effect of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

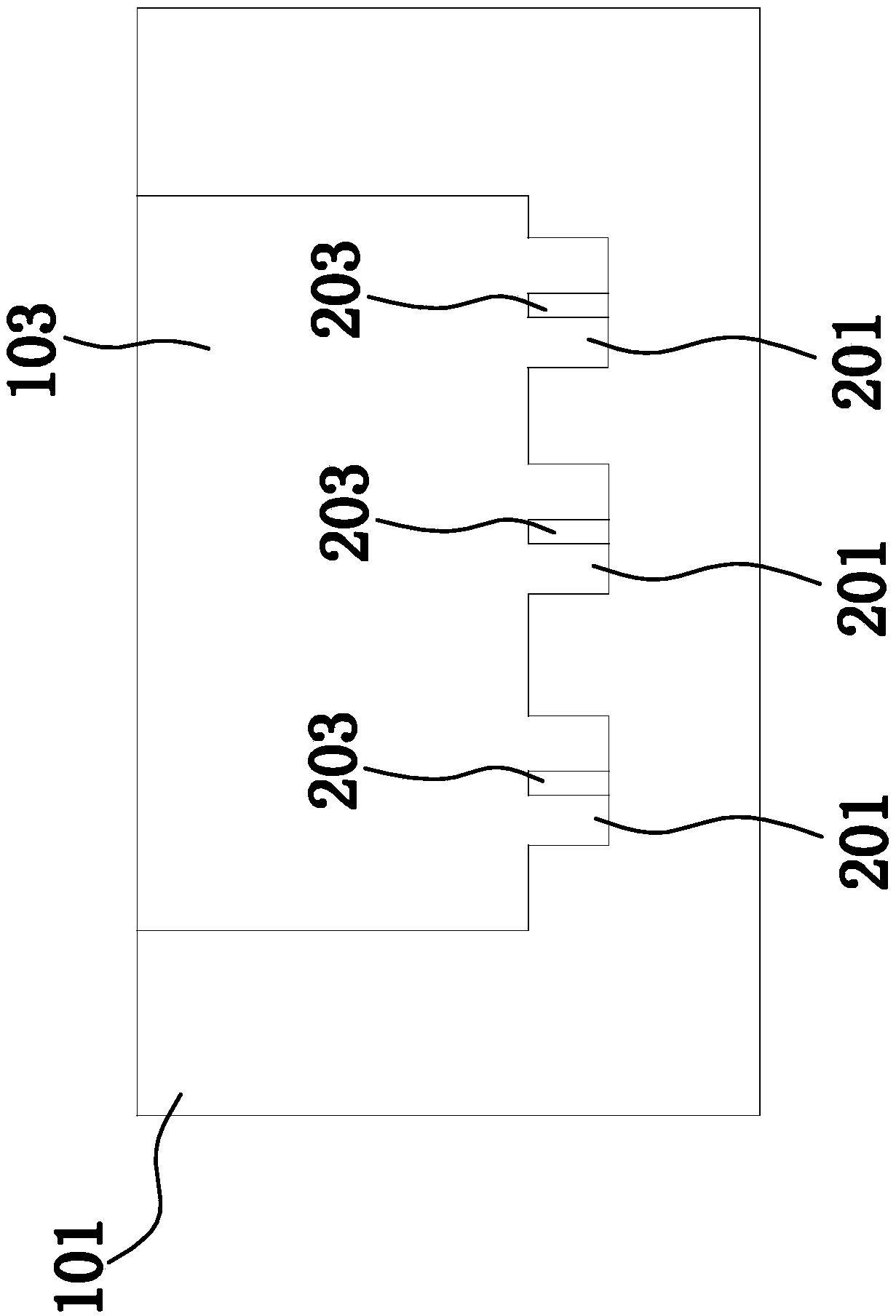

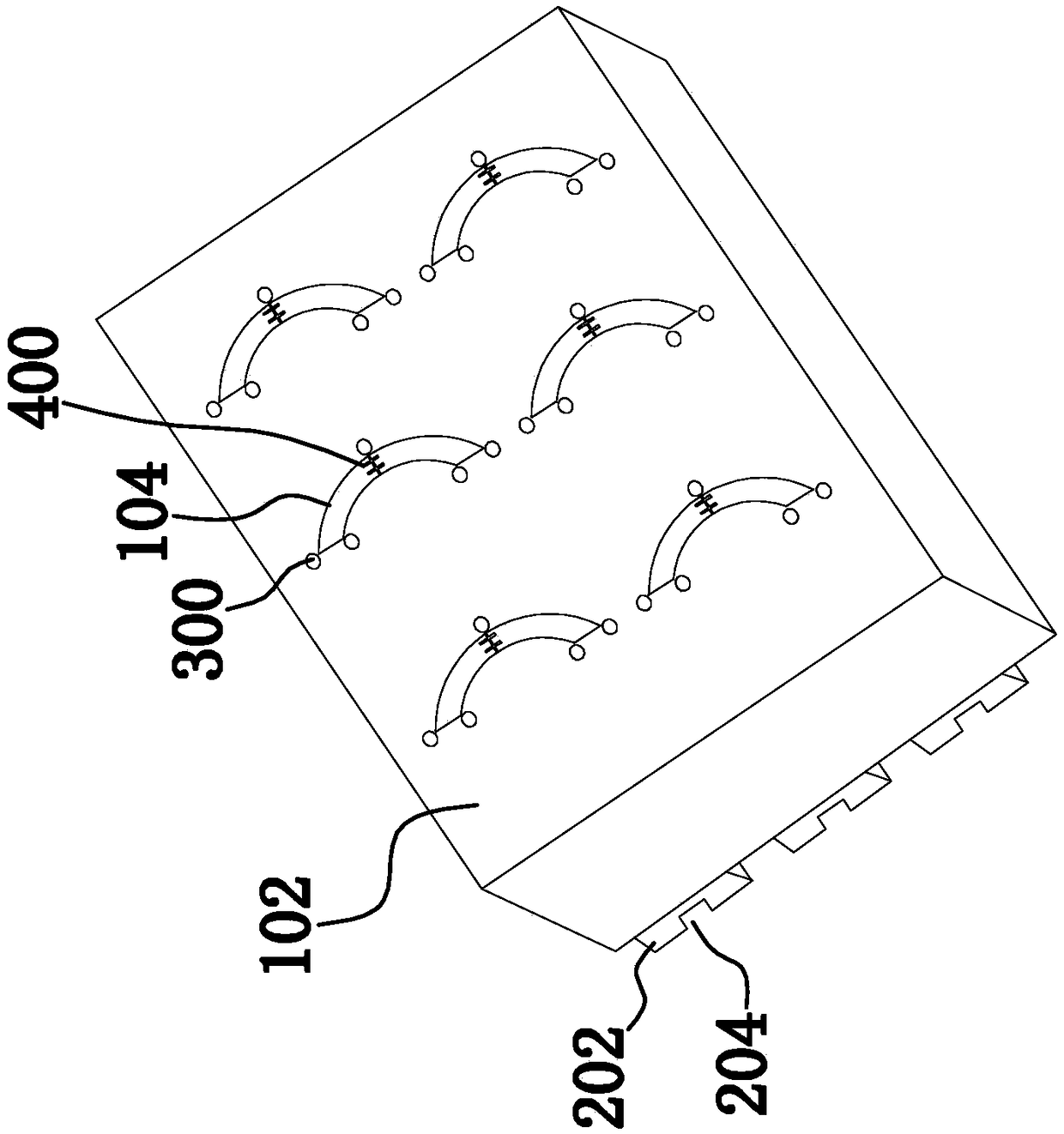

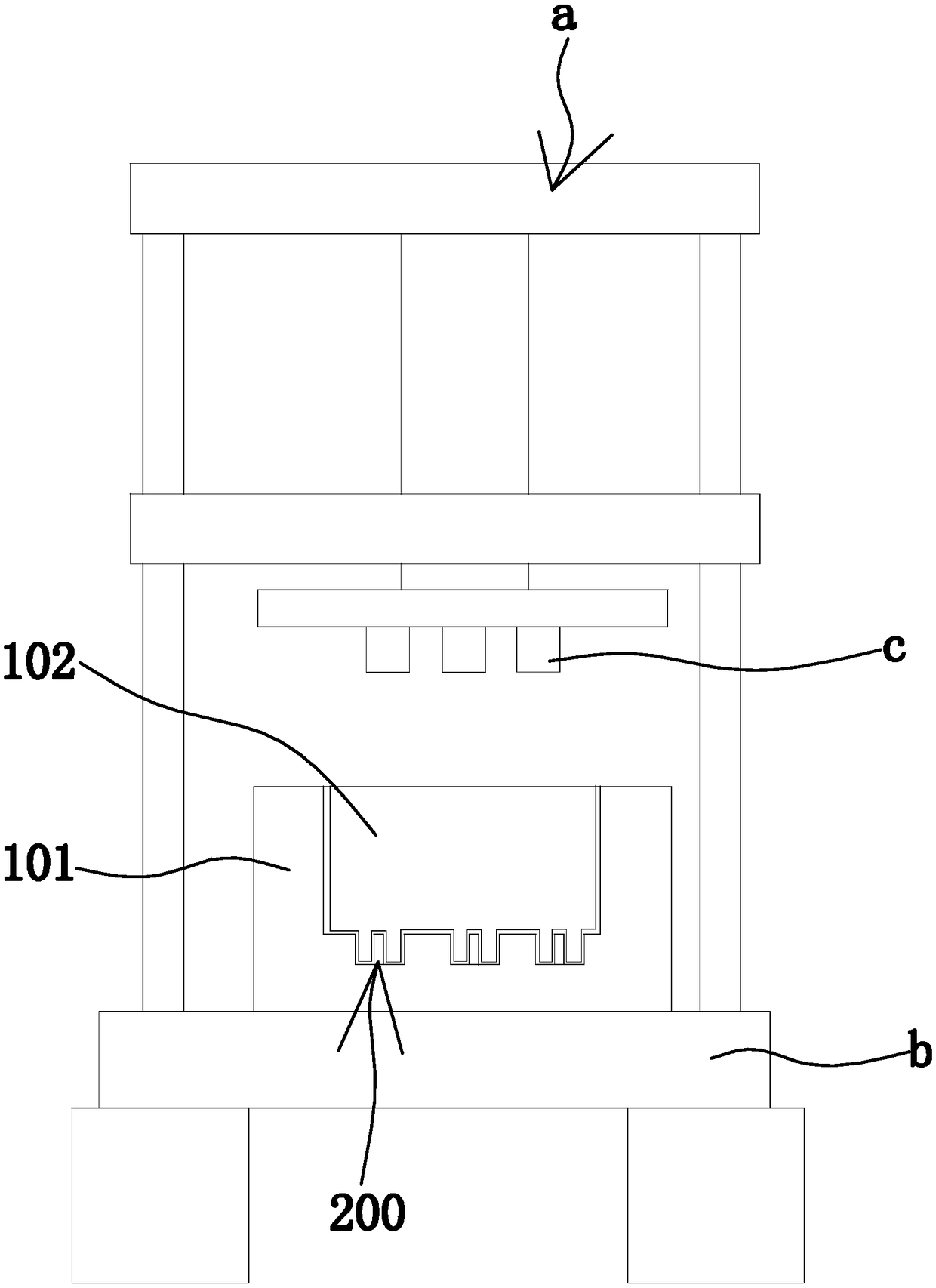

[0020] Such as Figures 1 to 4 As shown, the extrusion die for wear-resistant materials for this vehicle is set on the bearing platform b on the forging press a, including the disassembled mold mounting seat 101 located on the bearing platform b, which is characterized in that: the mold mounting seat 101 One side of the upper pressure head c close to the forging press a is provided with a die slot 103 for installing the die 102, and the die 102 is provided with a number of filling grooves 104 for filling brake pad friction materials. Die mounting base 101 is provided with die slot 103 for inserting die 102, so that die 102 is very convenient to take out from forging press a, so that it can be realized that there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com