Dope dyeing textile material color blending method

A technology for dope coloring and textile materials, applied in various fluid ratio control, non-electric variable control, instruments, etc., can solve the problems of incompatibility, inconsistency, color incongruity, etc., and achieve low light source influence, high color matching efficiency, and color matching high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

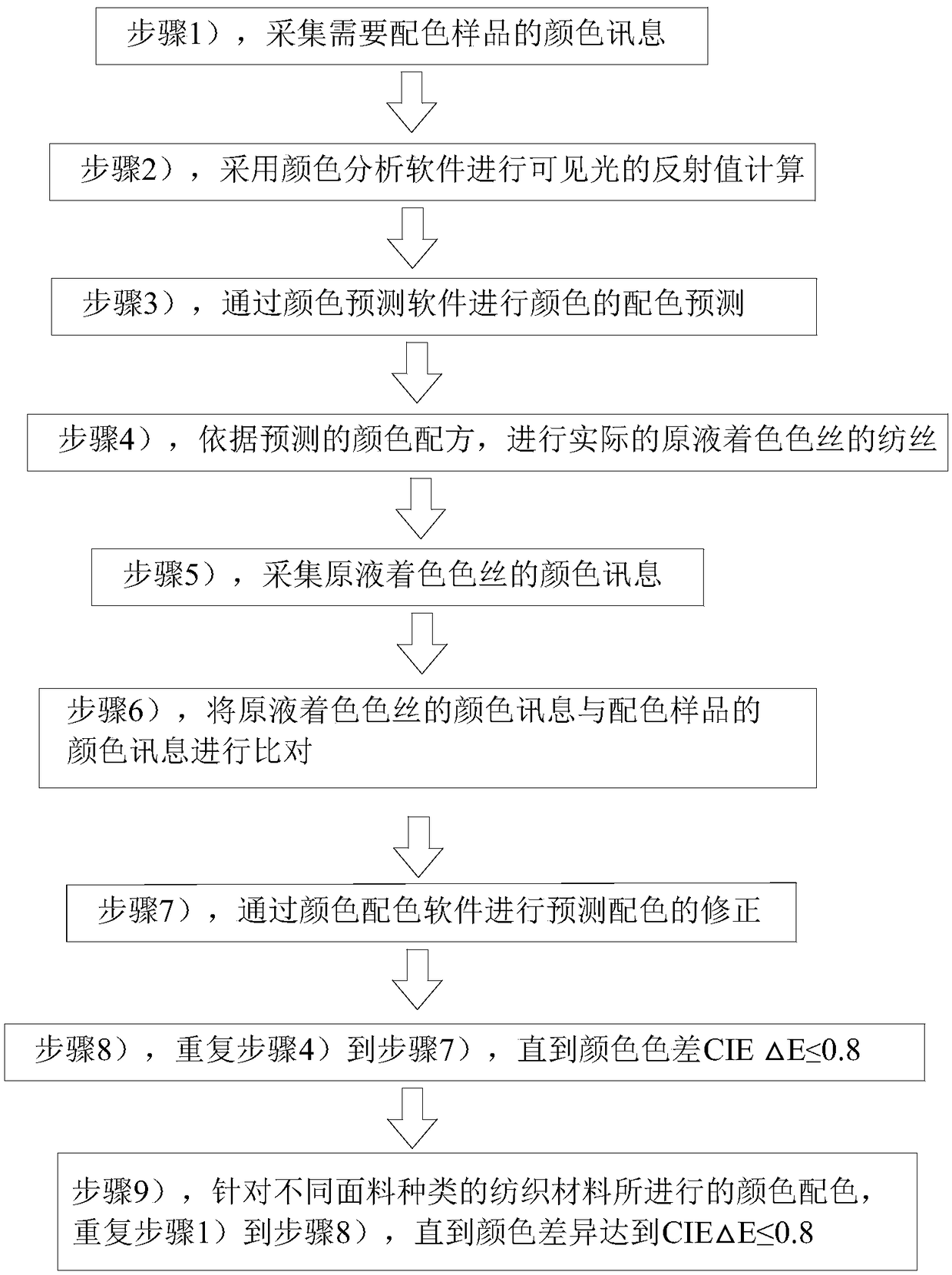

[0056] The color matching method of the dope dyed textile material of the present embodiment comprises the following steps:

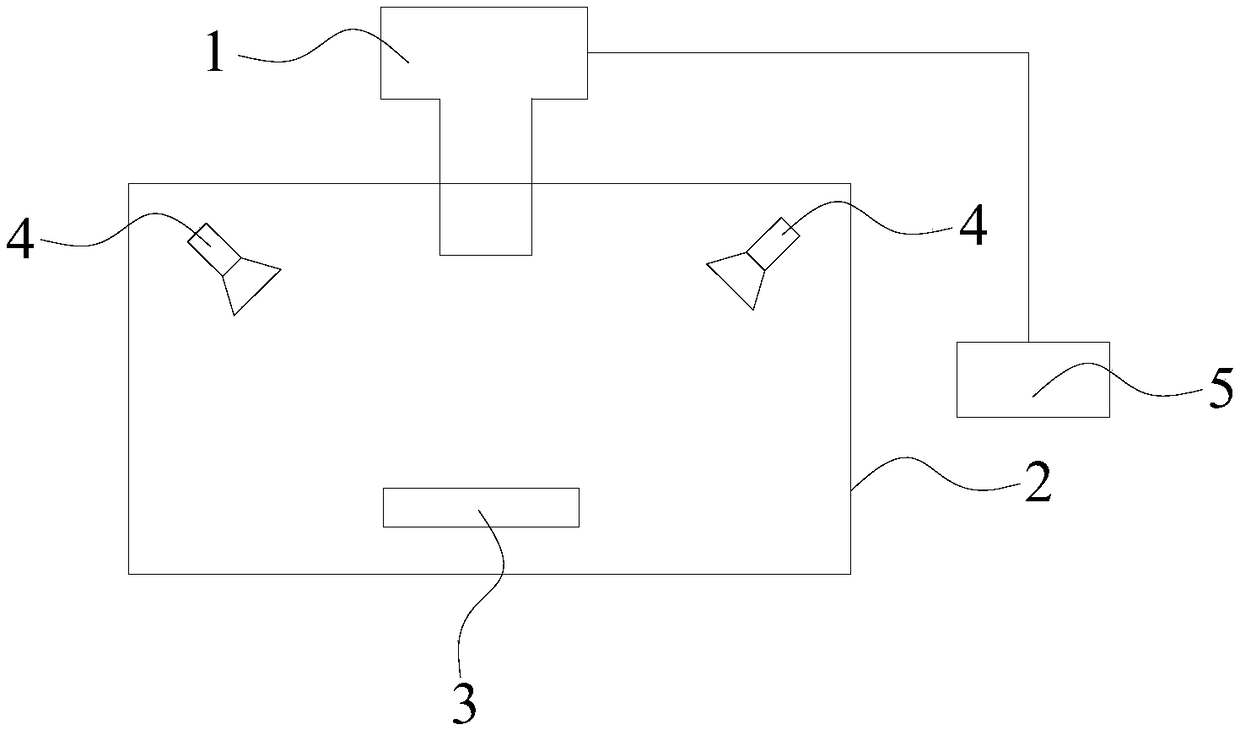

[0057] 1) In the color collection box, a high-definition camera is used to collect the color information of the color matching sample, wherein the light chromaticity of the light source collected for the color information is 6500K, and the lighting geometric condition is 45 degrees / 0 degrees;

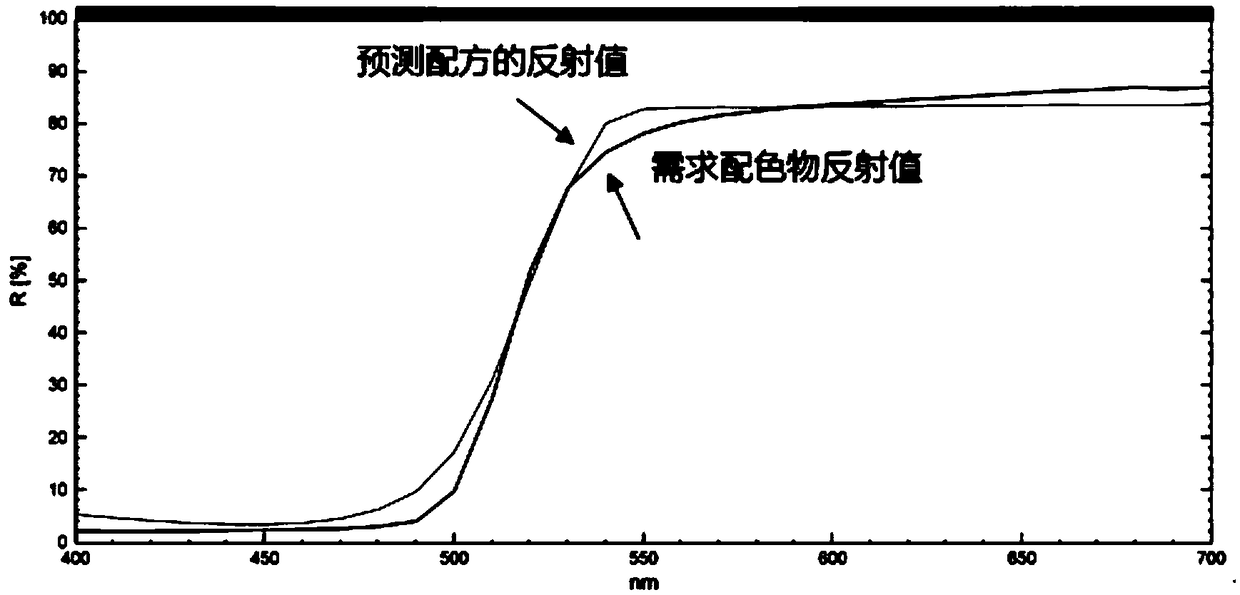

[0058] 2) The color collected in step 1) is used to calculate the reflection value of visible light in the interval of 400-700nm by using color analysis software;

[0059] 3) Pass the color reflection value calculated in step 2) through the color prediction software, and use the established basic data of reflection values of different colors and different concentrations to perform color matching prediction;

[0060] 4) According to the color matching predicted in step 3), the spinning of dope-colored yarn is carried out;

[0061] 5) Wind the corresponding yarn...

Embodiment 2

[0067] The color matching method of the dope dyed textile material of the present embodiment comprises the following steps:

[0068] 1) In the color collection box, a high-definition camera is used to collect the color information of the color matching sample, wherein the light chromaticity of the light source collected for the color information is 2800K, and the lighting geometric condition is 45 degrees / 0 degrees;

[0069] 2) The color collected in step 1) is used to calculate the reflection value of visible light in the interval of 400-700nm by using color analysis software;

[0070] 3) Pass the color reflection value calculated in step 2) through the color prediction software, and use the established basic data of reflection values of different colors and different concentrations to perform color matching prediction;

[0071] 4) According to the color matching predicted in step 3), the spinning of dope-colored yarn is carried out;

[0072] 5) Wind the corresponding yarn...

Embodiment 3

[0078] The color matching method of the dope dyed textile material of the present embodiment comprises the following steps:

[0079] 1) In the color collection box, a high-definition camera is used to collect the color information of the color matching samples, wherein the light chromaticity of the light source collected for the color information is 4200K, and the lighting geometric condition is 45 degrees / 0 degrees;

[0080] 2) The color collected in step 1) is used to calculate the reflection value of visible light in the interval of 400-700nm by using color analysis software;

[0081] 3) Pass the color reflection value calculated in step 2) through the color prediction software, and use the established basic data of reflection values of different colors and different concentrations to perform color matching prediction;

[0082] 4) According to the color matching predicted in step 3), the spinning of dope-colored yarn is carried out;

[0083] 5) Make the corresponding sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com