Rockfill density measuring method based on additional mass process theoretical measuring plate

An additional mass method and density measurement technology, which is applied in the field of engineering geophysical exploration, can solve the problems of difficult expansion of digital measurement board, single measurement surface, and incapable of measurement board test, etc., and achieve perfect theoretical support, simple calculation and wide testing range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

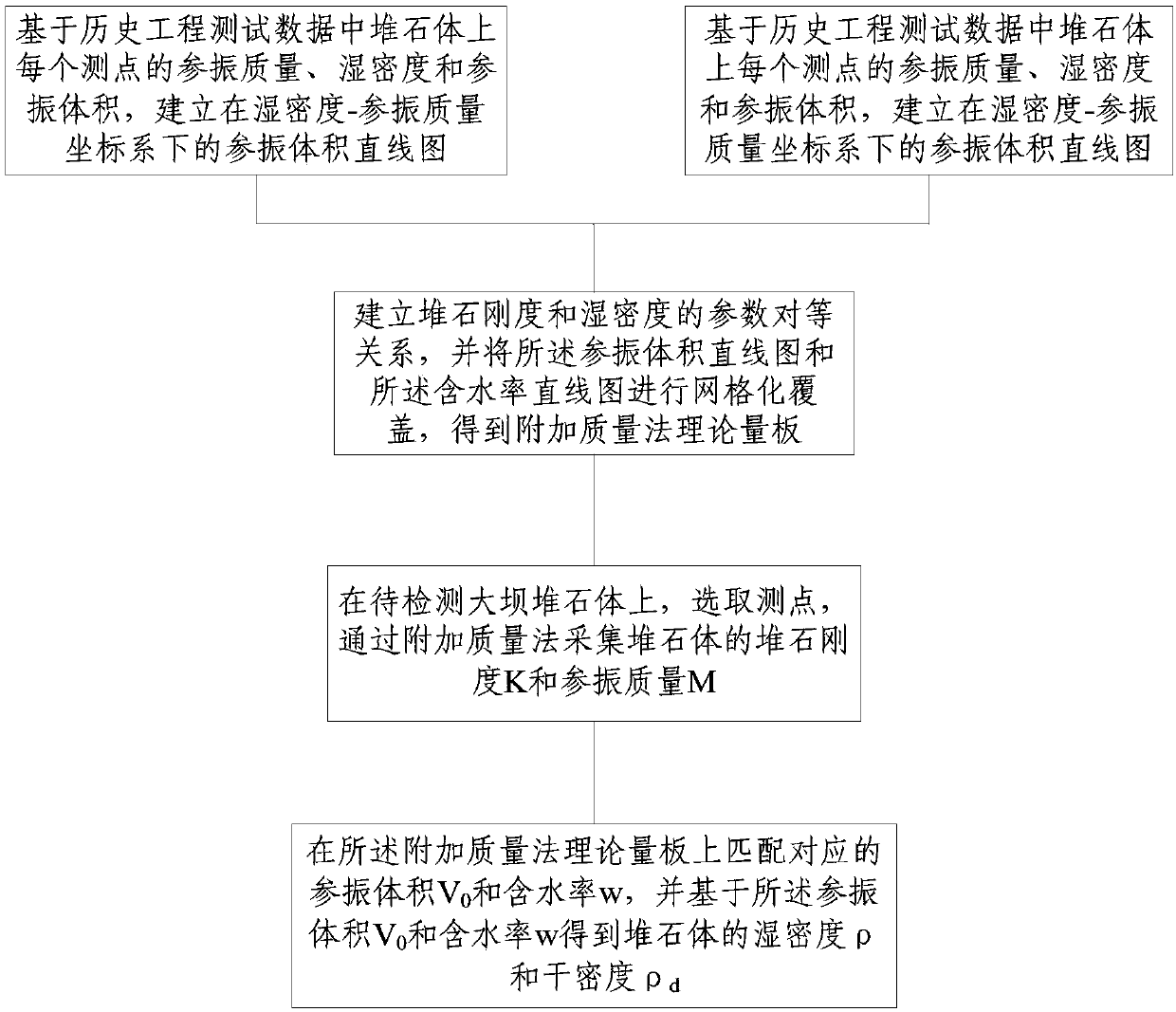

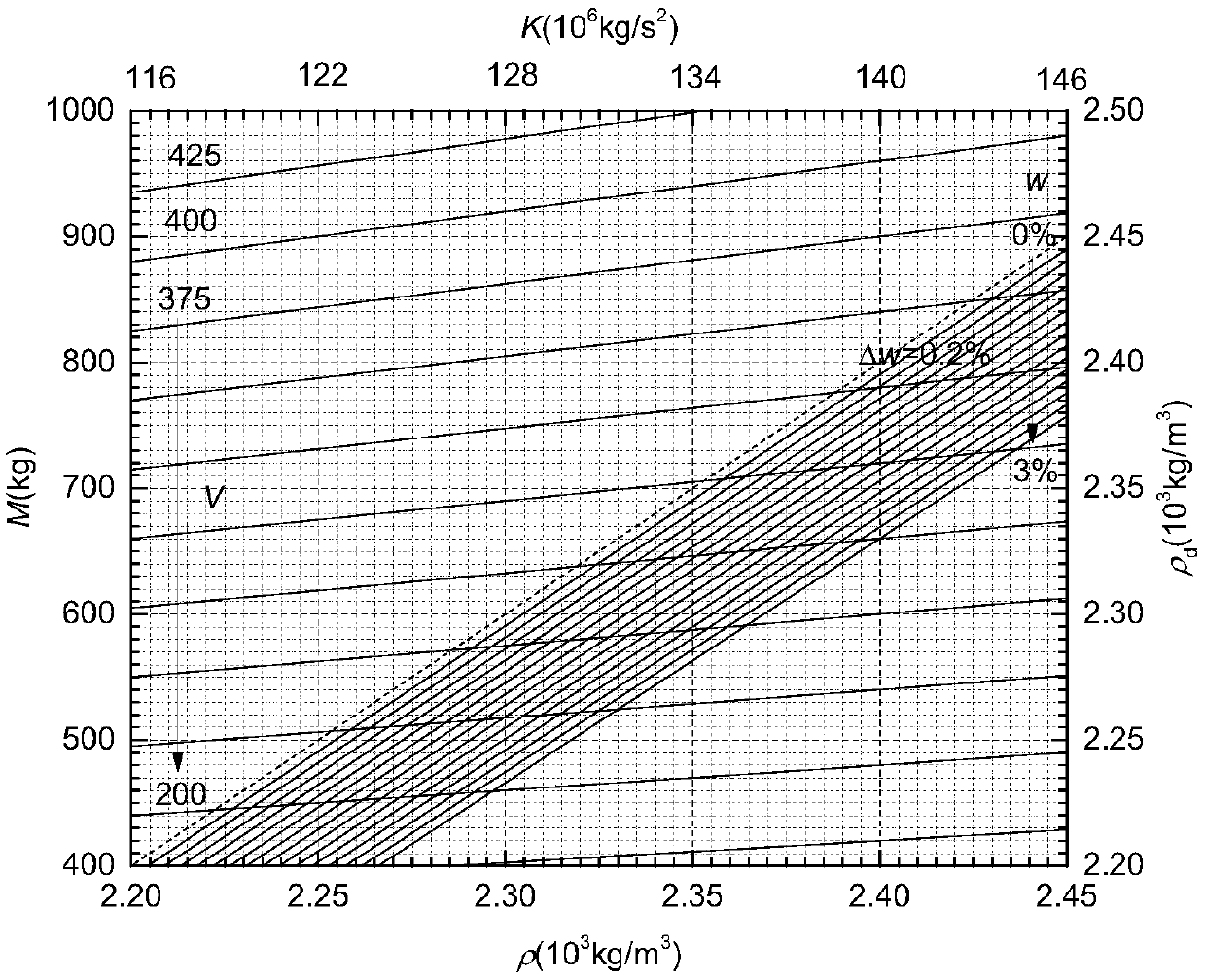

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0026] In the construction process of rock-fill dams, the density of rock-fill bodies is an important parameter to reflect the quality of the dam. Therefore, the detection of the density of rock-fill bodies is of great significance to ensure the quality of dam construction. Common rockfill density detection methods in engineering include direct method and indirect method. The direct method is usually the pit measurement method. Although this method is relatively accurate, it has defects such as low efficiency and high cost. Indirect methods include compaction settlement observation method, vibrating rolling accelerometer method, controlling rolling parameter method, static...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com