Double-swashplate plunger pump

A technology for swash plate plunger pumps and plunger pumps, which is applied in the direction of pumps, multi-cylinder pumps, liquid displacement machines, etc., and can solve complex structures, mixed oil and water, and inability to accurately realize stepless adjustment of displacement of plunger pump speed and steering issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

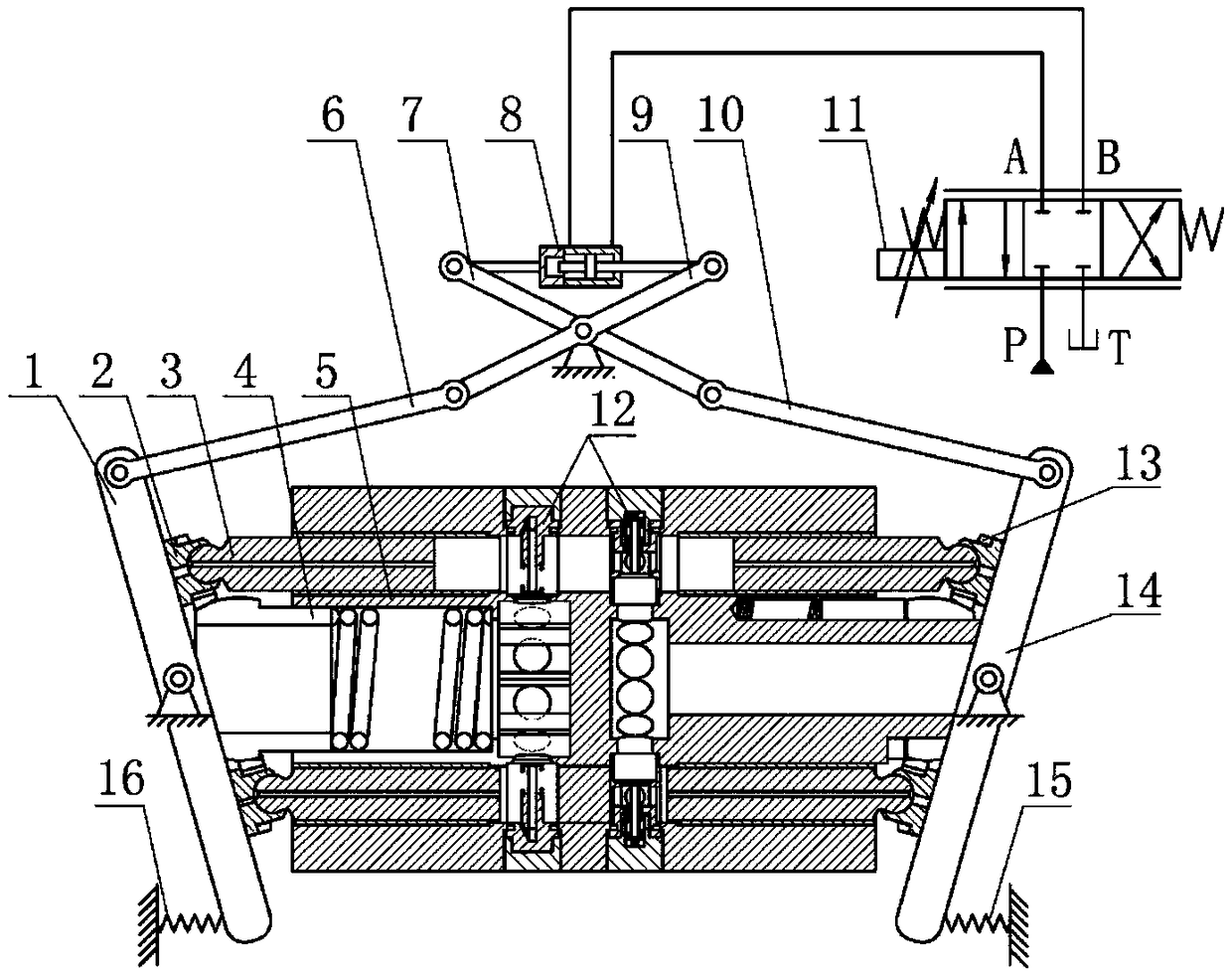

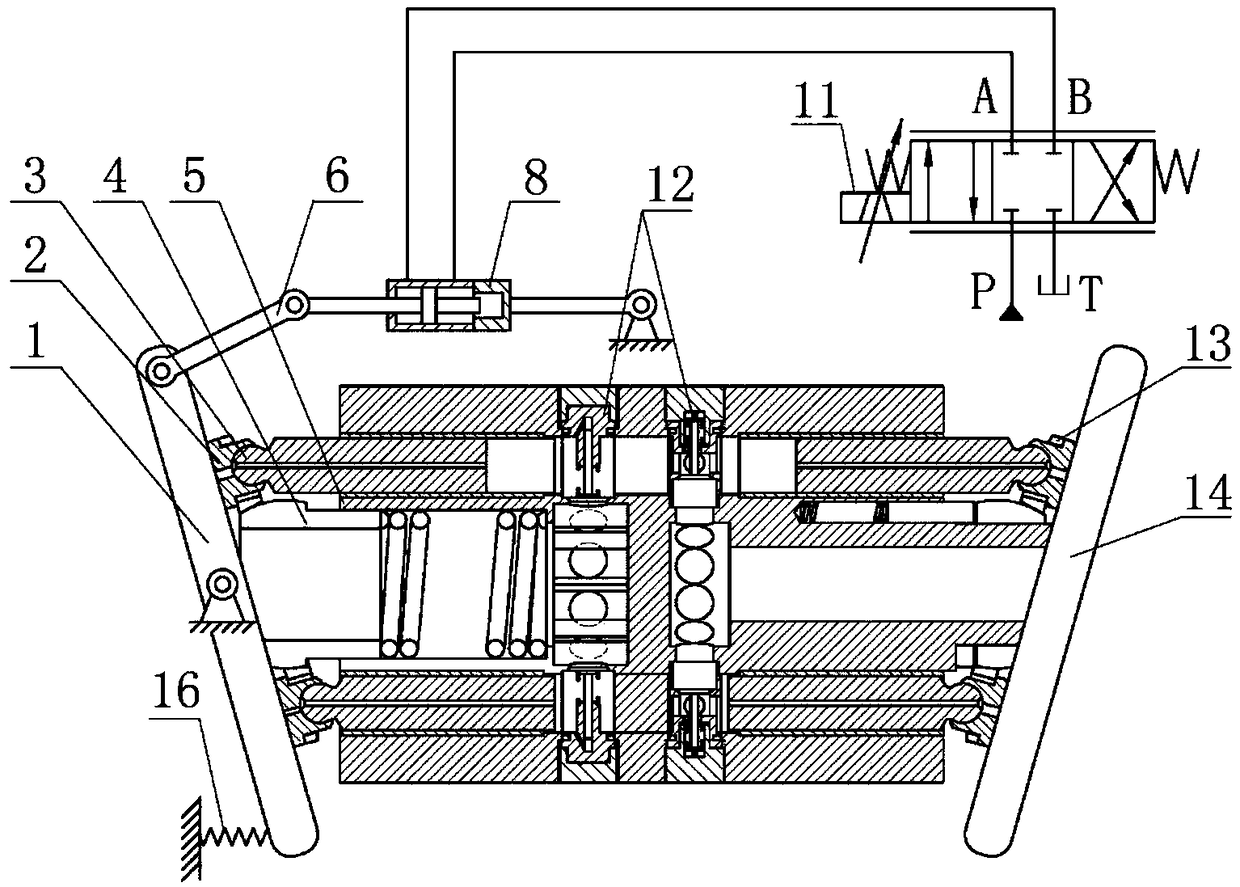

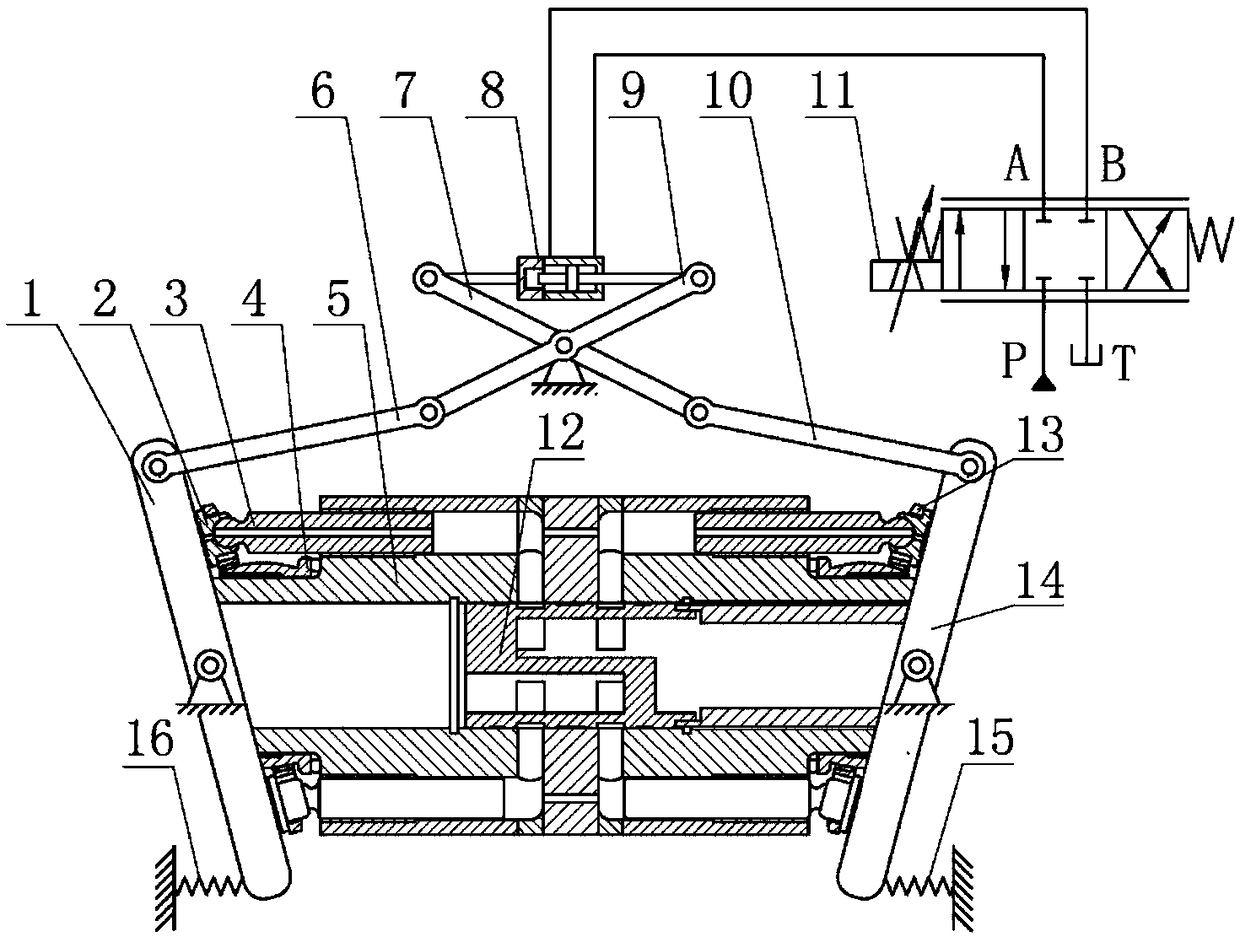

[0034] Such as Figure 1 to Figure 4 As shown, a double swash plate plunger pump includes a cylinder body 5, a plurality of plungers 3, a flow distribution device 12, a double swash plate assembly and a variable adjustment mechanism. Among them, in the rotatable cylinder body 5, a plurality of corresponding plunger holes are arranged at both ends along the circumferential direction, and suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com