A hydraulic variable motor speed control system for recovery of natural gas residual pressure energy

A variable motor and speed control system technology, applied in the field of natural gas residual pressure energy recovery and utilization, can solve the problems of high cost, high price, overhaul and other problems, and achieve the effect of high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

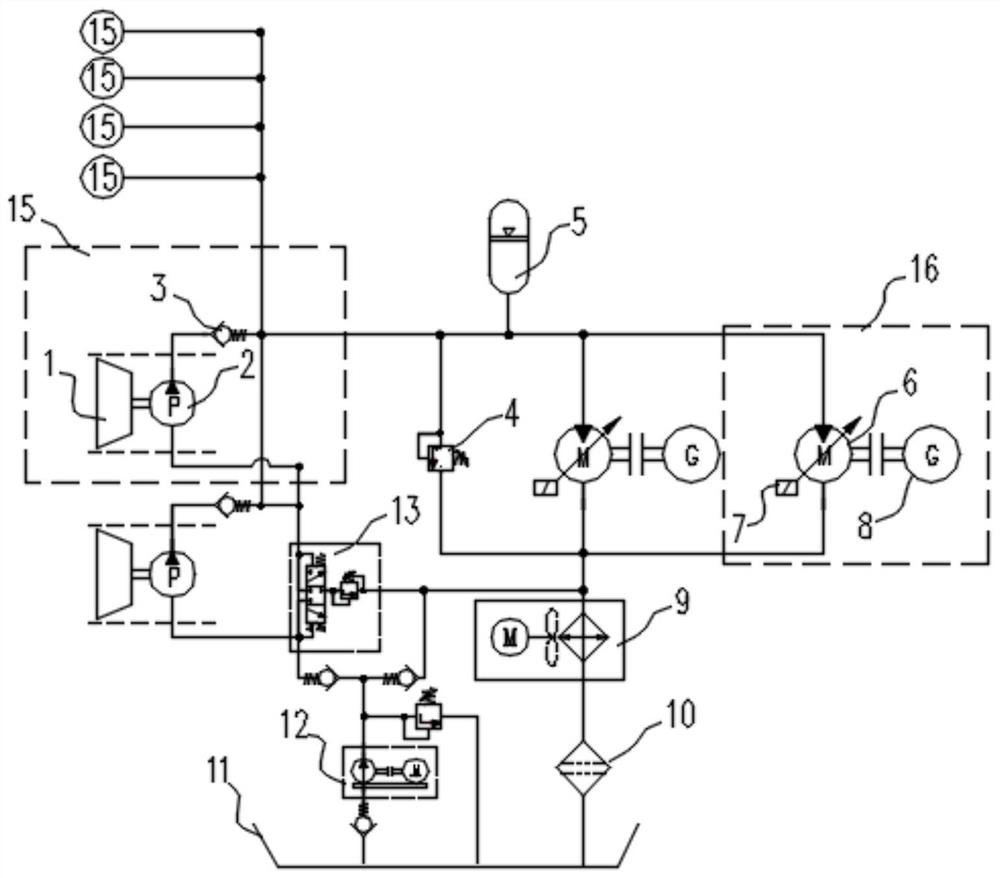

[0044] Please refer to figure 1 , figure 1 It is a structural block diagram of a closed-type hydraulic variable motor 6 speed regulating system for recovering residual pressure energy of natural gas according to the present invention. A closed hydraulic variable speed motor 6 speed control system for recovering residual pressure energy of natural gas, the closed hydraulic variable speed motor 6 speed control system includes an expander 1, a hydraulic pump 2, an accumulator 5, a variable variable motor 6, Controller 7, natural gas pipeline 14; described expander 1 and hydraulic pump 2 are connected together, and placed in natural gas pipeline 14; The quantity in described natural gas pipeline 14 is at least one, and each natural gas pipeline 14 A matching expander 1 and a hydraulic pump 2 are provided; and each hydraulic pump 2 is connected in parallel; the output end of the hydraulic pump 2 is connected to the one-way valve 3; the output end of the one-way valve 3 A safety v...

Embodiment 2

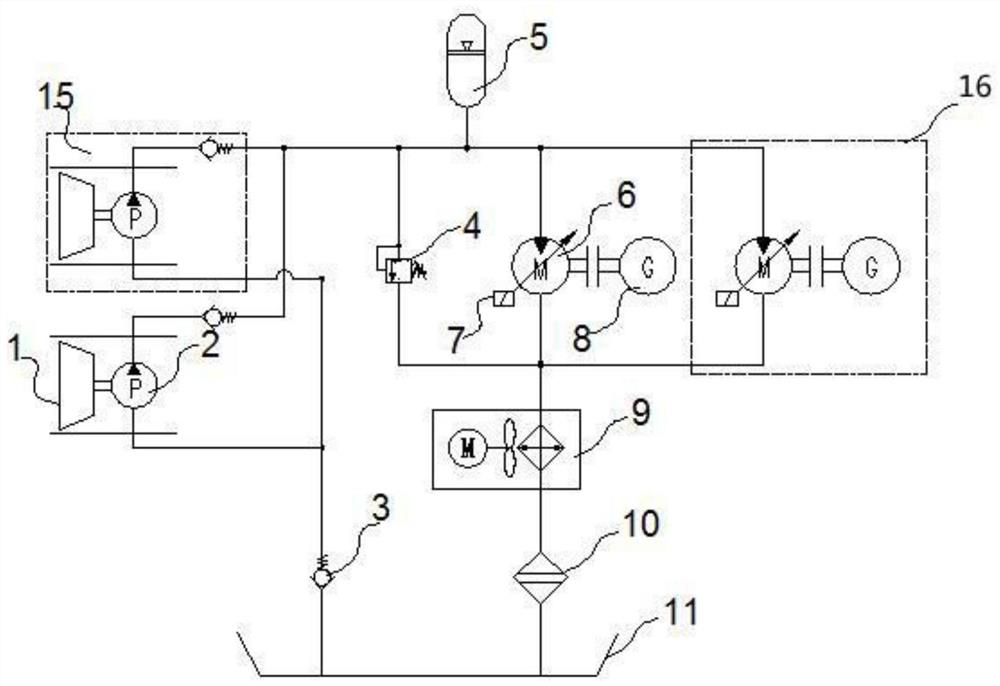

[0062] Please refer to figure 2 , figure 2 It is a structural block diagram of another open hydraulic variable motor speed regulating system for recovering residual pressure energy of natural gas according to the present invention. This embodiment is basically the same as Embodiment 1, the difference is that the hydraulic variable motor speed control system in Embodiment 1 is a closed structure, while the hydraulic variable motor speed control system in this embodiment is an open structure, that is In this embodiment, the flushing valve 13 and the oil supply device 12 are not provided, and the oil tank 11 is directly connected with the hydraulic pump 2 through the check valve 3, which simplifies the structure of the whole system. Secondly, in this embodiment, the variable motor 6, the controller 7, and the generator 8 form a power frequency power generation unit 16, and there is at least one power frequency power generation unit 16, so that the residual pressure of multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com