High-quality printing and dyeing device for textile fabric

A high-quality technology for textile fabrics, which is applied in the processing of textile material equipment configuration, textile material processing, spray/jet textile material processing, etc. It can solve the problems of poor dye chromaticity uniformity, low dye utilization rate, and poor dyeing effect And other problems, to achieve the effect of improving the utilization rate, improving the uniformity of spray dyeing, and improving the uniformity of chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

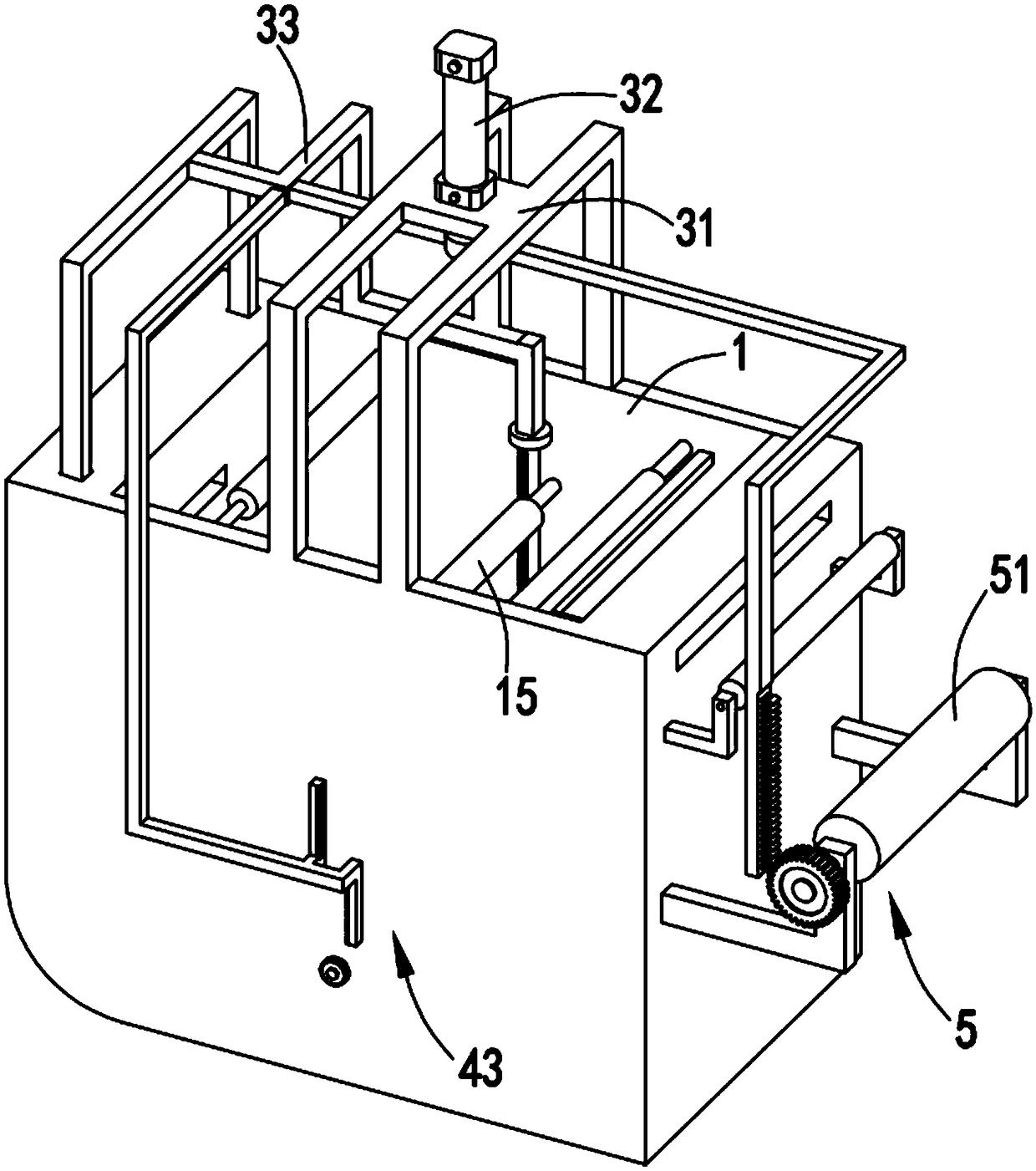

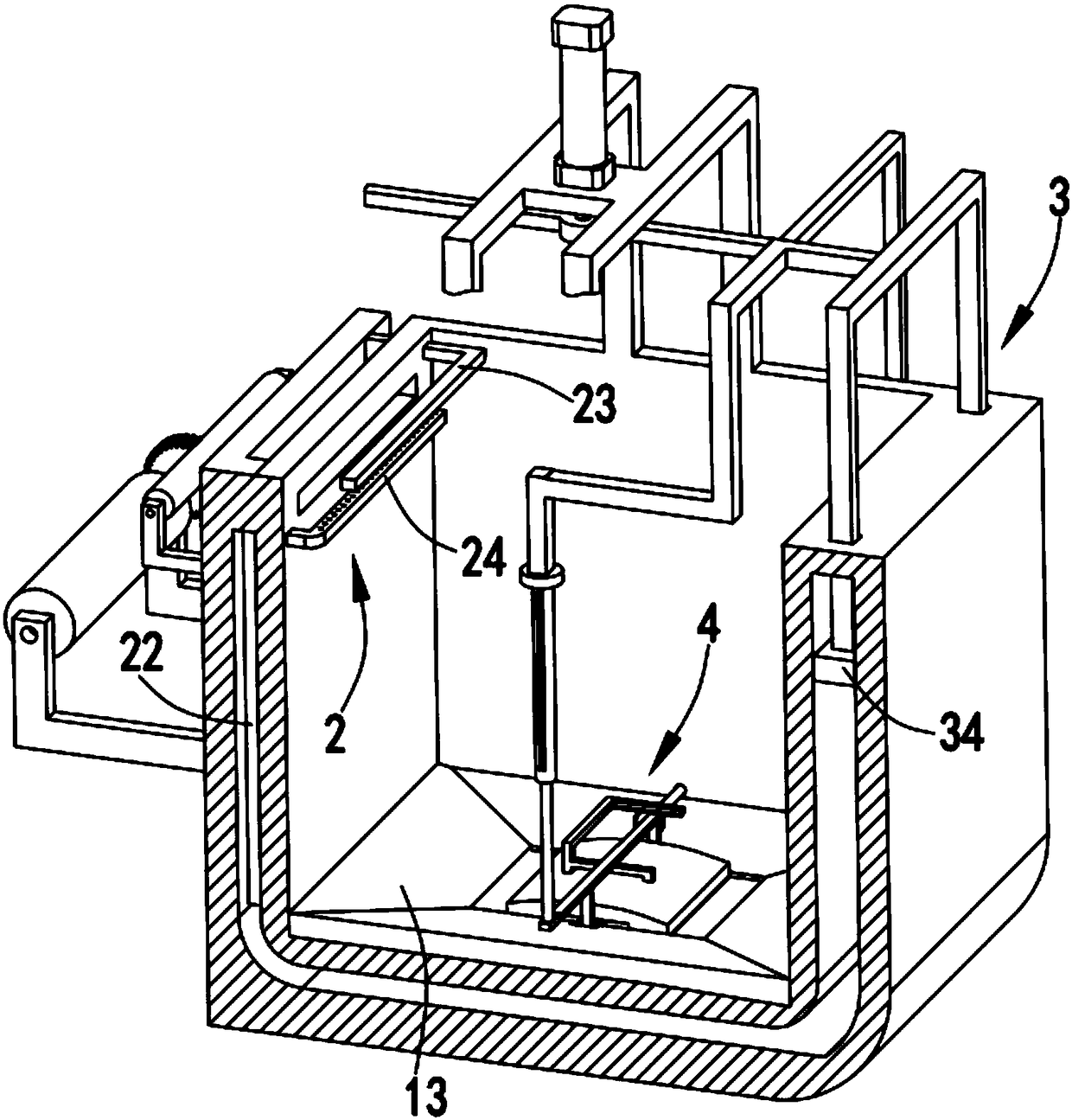

[0039] Such as Figure 1 to Figure 9 As shown, a high-quality printing and dyeing device for textile fabrics includes a dye box 1, an extrusion cavity 11 is opened in the left side of the dye box 1, and a flow guide channel communicating with the extrusion cavity 11 is opened in the bottom edge 12, the right side of which is provided with a spraying mechanism 2 communicating with the diversion channel 12;

[0040] The extruding chamber 11 is provided with an extruding mechanism 3, and the extruding mechanism 3 is used to extrude the dye liquor in the extruding chamber 11 so that the dye liquor is sprayed from the dyeing mechanism 2 to the fabric after passing through the diversion channel 12. 10 on;

[0041]A grinding mechanism 4 is provided at a position close to the bottom edge in the dye box 1, and the grinding mechanism 4 includes a lower grinding assembly 41 arranged above the flow guiding channel 12, an upper grinding assembly 42 arranged above the lower grinding assemb...

Embodiment 2

[0055] Such as figure 1 , Figure 6 and Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is: further, the fabric winding mechanism 5 includes a winding roller 51 arranged on the right side of the dye box 1, and a third gear coaxially arranged with the winding roller 51 52 and the driver 53 fixed on the bracket 33, the driver 53 drives the third gear 52 to rotate with the winding roller 51 when the bracket 33 moves downward, and the third gear 52 and the winding roller 51 rotate together when it moves upward with the bracket 33. The winding roller 51 does not rotate.

[0056] Further, the driving member 53 includes a driving rod 531, a tooth 532 rotatably arranged on the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com