Biological organic fertilizer

A bio-organic fertilizer and feces technology, applied in the field of organic fertilizer, can solve the problems of single raw material, limited nutrient supply, soil and crop heavy metal pollution, etc., achieve and regulate crop growth, promote crop growth, and be environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

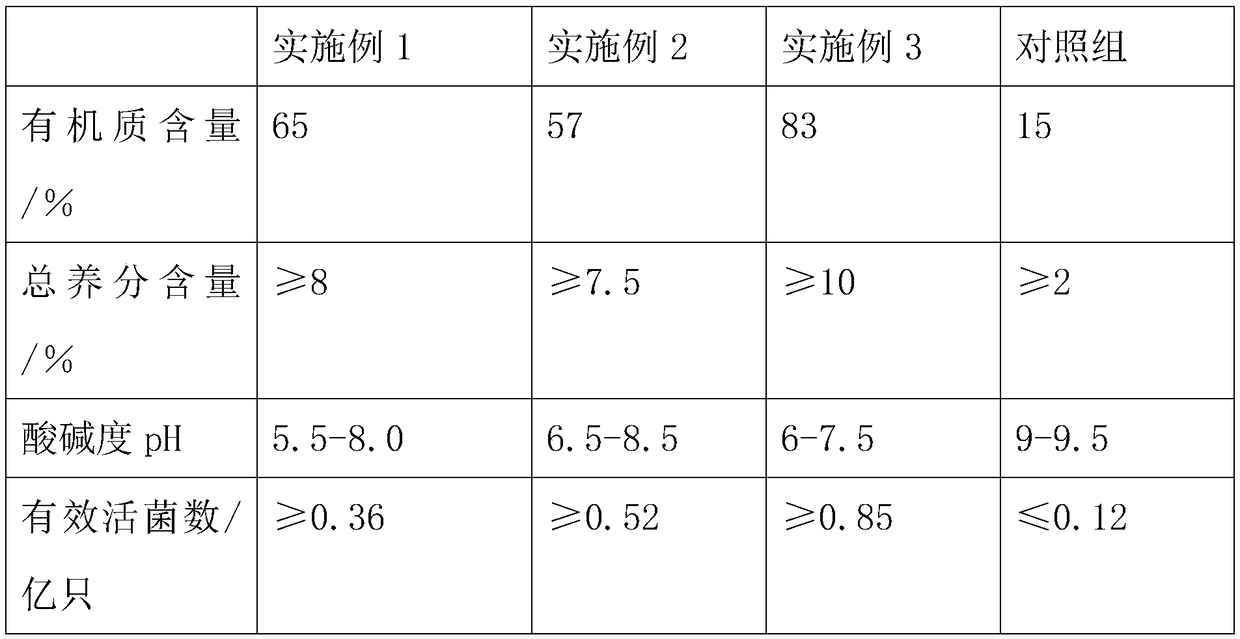

Examples

Embodiment 1

[0018] 1): Breeding manure, wheat bran, fruit pomace, vegetable rotten leaves, corn stalks, acacia leaves, urea, starter and water are selected as raw materials, and the component percentages of the raw materials are respectively: 30% of cultured manure, 8% of wheat bran, 10% of fruit pomace, 11% of rotten vegetable leaves, 12% of corn stalks, 9% of acacia leaves and 16% of water, the raw materials are stirred and turned by an automatic compost turning machine;

[0019] 2): Add urea and starter to the mixer, and continue to stir the raw materials in 1), after the stirring is completed, aerate the obtained mixture, so that the aerated mixture can be held into a ball, let go The effect of both dispersing, wherein the percentage by weight that urea and leavening agent add are respectively 3.4% and 0.6%;

[0020] 3): Lay a layer of plastic film on the bottom and around the fermentation tank, and disinfect the fermentation tank and the film. After the disinfection is completed, pou...

Embodiment 2

[0023] 1): Breeding manure, wheat bran, fruit pomace, rotten vegetable leaves, corn stalks, acacia leaves, urea, starter and water are selected as raw materials, and the component percentages of the raw materials are respectively: 25% of cultured manure, 9% of wheat bran, 11% of fruit pomace, 12% of rotten vegetable leaves, 13% of corn stalks, 10% of acacia leaves and 15% of water, the raw materials are stirred and turned by an automatic compost turning machine;

[0024] 2): Add urea and starter to the mixer, and continue to stir the raw materials in 1), after the stirring is completed, aerate the obtained mixture, so that the aerated mixture can be held into a ball, let go The effect of both dispersing, wherein the percentage by weight that urea and leavening agent add are respectively 4.2% and 0.8%;

[0025] 3): Lay a layer of plastic film on the bottom and around the fermentation tank, and disinfect the fermentation tank and the film. After the disinfection is completed, po...

Embodiment 3

[0028] 1): Breeding manure, wheat bran, fruit pomace, vegetable rotten leaves, corn stalks, acacia leaves, urea, starter and water are selected as raw materials, and the component percentages of the raw materials are respectively: 35% of cultured manure, 7% of wheat bran, 9% of fruit pomace, 9% of rotten vegetable leaves, 10% of corn stalks, 7% of acacia leaves and 18% of water, the raw materials are stirred and turned by an automatic turning machine;

[0029] 2): Add urea and starter to the mixer, and continue to stir the raw materials in 1), after the stirring is completed, aerate the obtained mixture, so that the aerated mixture can be held into a ball, let go The effect of both dispersion, wherein the percentage by weight of urea and leavening agent added is respectively 4% and 1%;

[0030] 3): Lay a layer of plastic film on the bottom and around the fermentation tank, and disinfect the fermentation tank and the film. After the disinfection is completed, pour the mixture o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com